Exhaust device

A technology of exhaust device and mounting plate, applied in the direction of fuel tank safety measures, can solve problems such as poor stealth effect of aircraft, and achieve the effect of ensuring electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

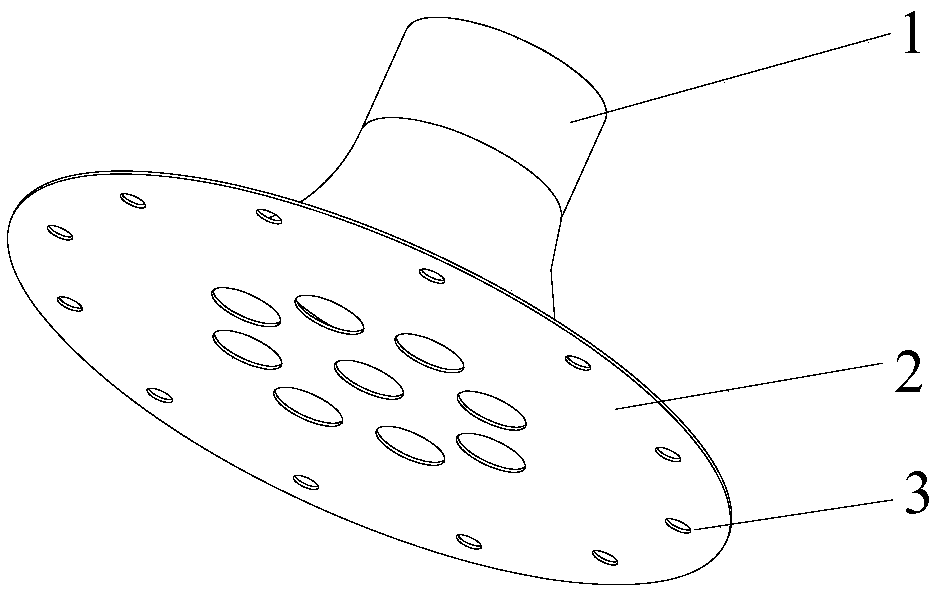

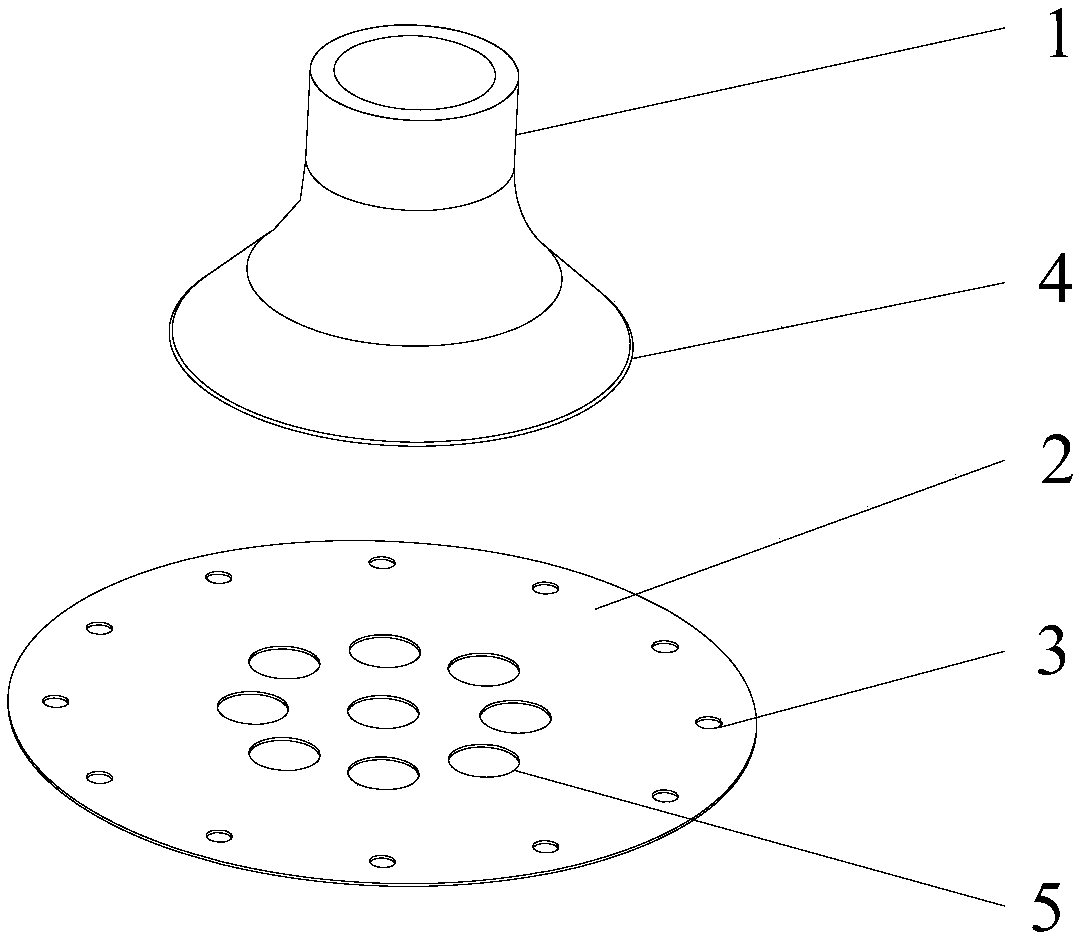

[0014] An exhaust device of the present invention is composed of a diffuser pipe 1 and a mounting plate 2 , the diffuser pipe 1 is an inner hollow structure, one end is a straight pipe section, and the other end is a bell mouth 4 . The mounting plate 2 is provided with a ventilation hole 5 and a mounting hole 3, the mounting hole 3 is used to connect the exhaust device with the aircraft surface skin structure, and the ventilation hole 5 is used to communicate with the fuel tank ventilation pipeline and the external atmospheric environment to realize Fuel tank vent function. The bell mouth 4 end of the diffuser tube 1 and the mounting plate 2 are combined into a whole through welding, and the vent hole 5 is located in the inner cavity of the bell mouth 4 after welding.

[0015] The straight pipe section end of diffusion pipe 1 is 1mm larger than the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com