Cement bag collection device for road construction

A technology for road construction and collection devices, which is applied in the direction of stacking receiving devices, transportation and packaging, and sending objects, etc., which can solve problems such as polluting the environment, blowing cement bags, and having no cement bag collection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

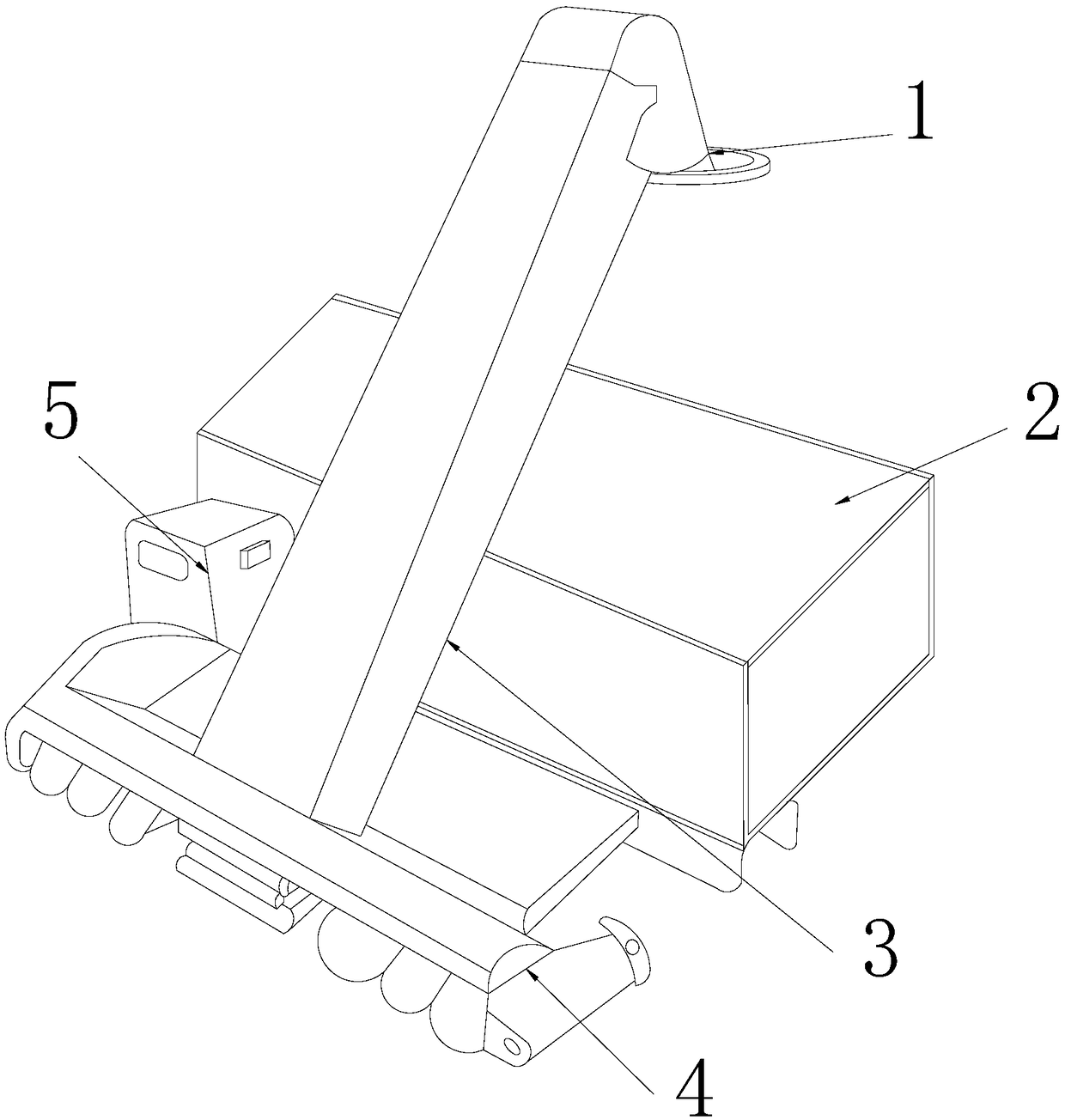

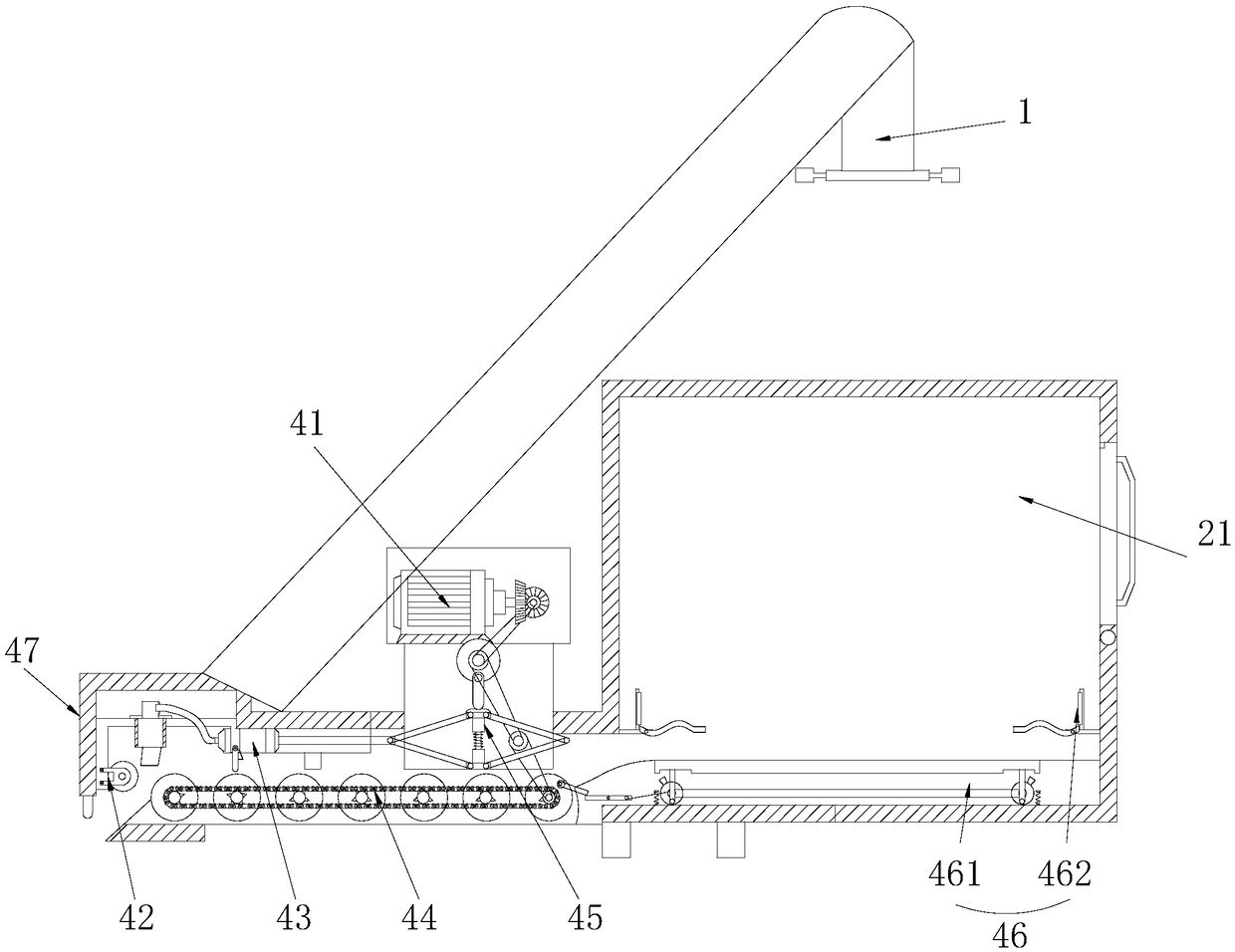

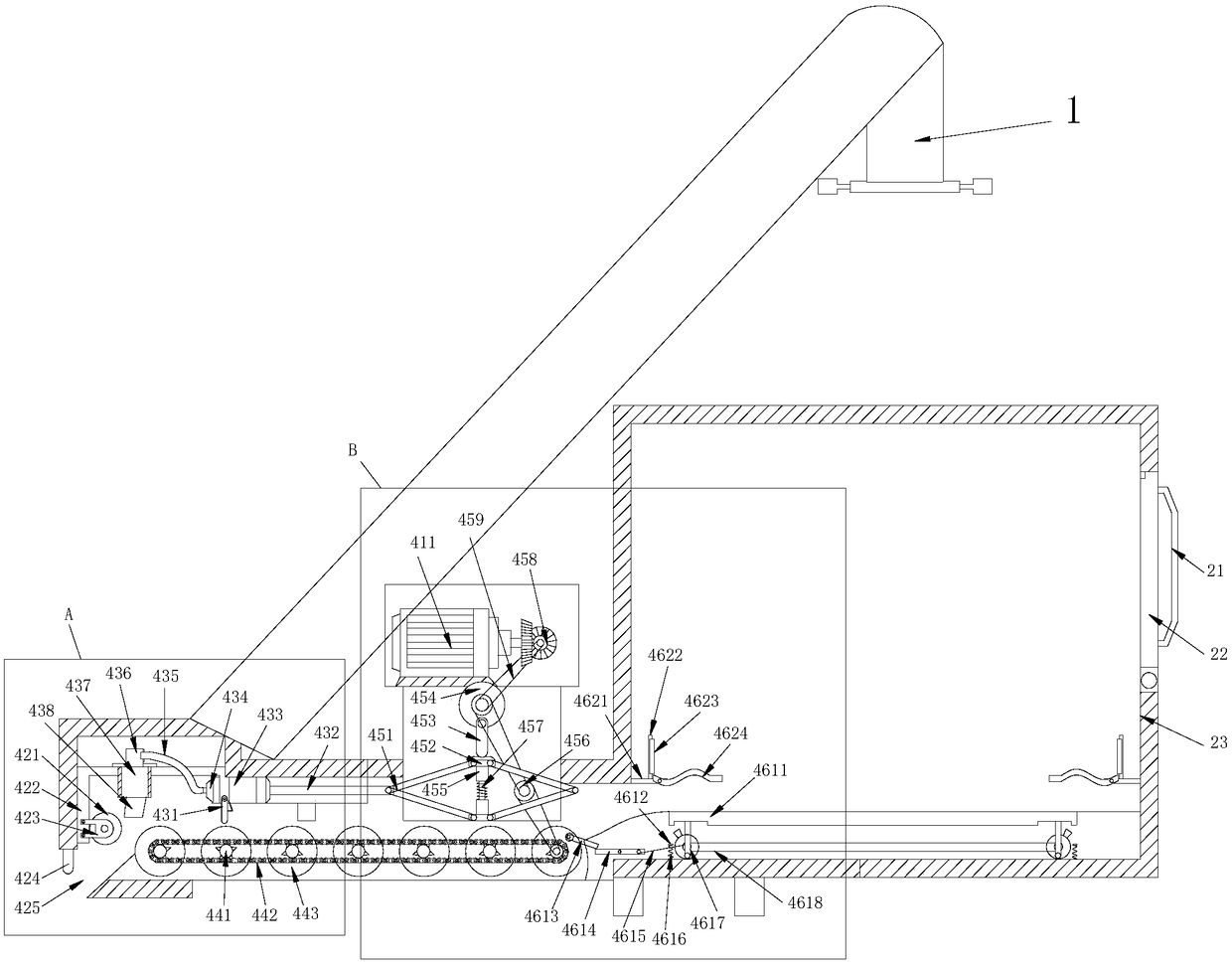

[0024] see Figure 1-Figure 5, the present invention provides a cement bag collection device for road construction, its structure includes a handrail 1, a storage box 2, a diagonal brace 3, a flat absorption structure 4, and a motor box 5, and the flat absorption structure 4 is obliquely installed with A diagonal brace 3, the head end of the diagonal brace 3 is fixed with a handrail 1, and the flat absorption structure 4 is not only mechanically connected to the storage box 2 on one side thereof, but also fixedly connected to the motor box 5 on the top surface thereof. The absorption structure 4 is provided with a motor 41, an inlet leveling structure 42, a negative pressure structure 43, a roller transmission structure 44, a main body linkage structure 45, a pressure collecting structure 46, and a housing 47, and one end of the housing 47 is mechanically connected to the storage box 2 , the other end is equipped with an inlet flat structure 42, the upper and lower ends betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com