A treatment system for aviation oil wastewater

A technology of aviation oil and treatment system, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc. The effect of reducing calorific value emissions and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

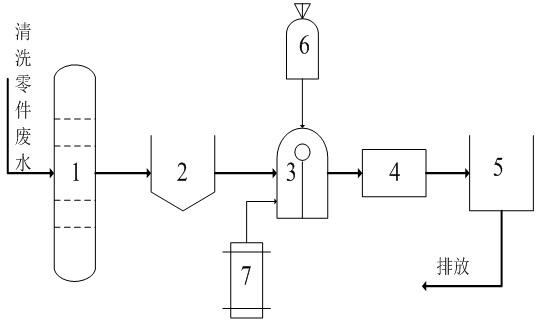

[0019] Such as figure 1A treatment system for aviation oil waste water is shown, which is characterized in that the system includes: 1-grid, 2-grit chamber, 3-full effect treatment tank, 4-MBR process, 5-reservoir, 6 - liquid nitrogen storage tank, 7-sodium hydroxide storage tank; wherein, the waste water from cleaning aviation parts is connected to the water inlet of the grid 1 through the pipeline, and the leaves contained in the waste water, the falling off Parts and other sundries are intercepted, and the outlet of the grille 1 is connected to the water inlet of the grit chamber 2 through a pipeline. The waste water is left standing in the grit chamber 2 for 60 minutes. Above, sand and gravel and other particulate matter settle at the bottom under the action of gravity, and an automatic slag scraper is provided at the bottom of the sediment tank 2. After the waste water is discharged, the slag scraper discharges the garbage out of the pool. The water outlet of the grit ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com