Drum type washing machine

A drum washing machine and inner drum technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of being unable to clean, easily accumulating dirt, and being unable to expand the washing capacity of the washing machine, so as to achieve increased capacity and volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

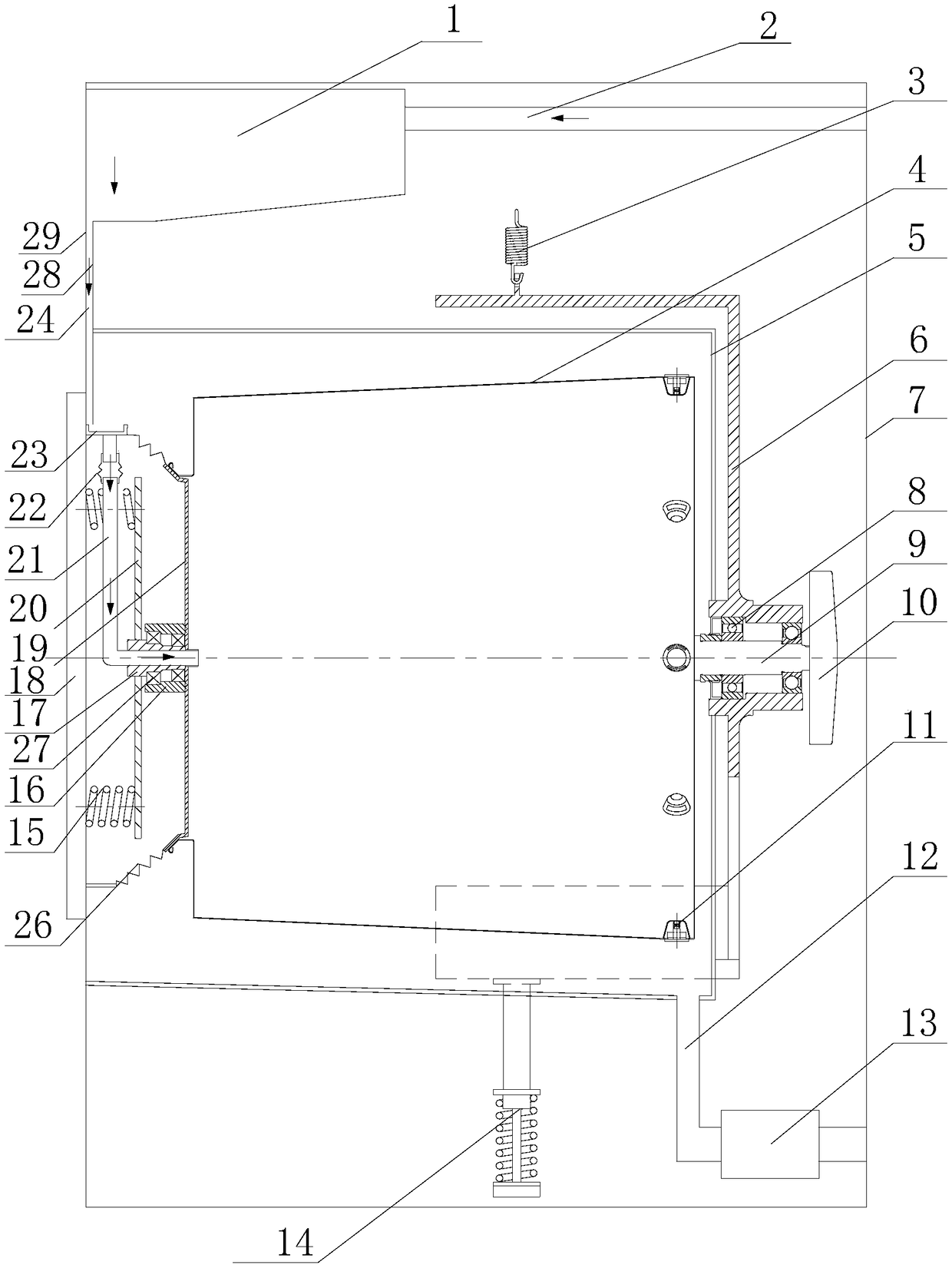

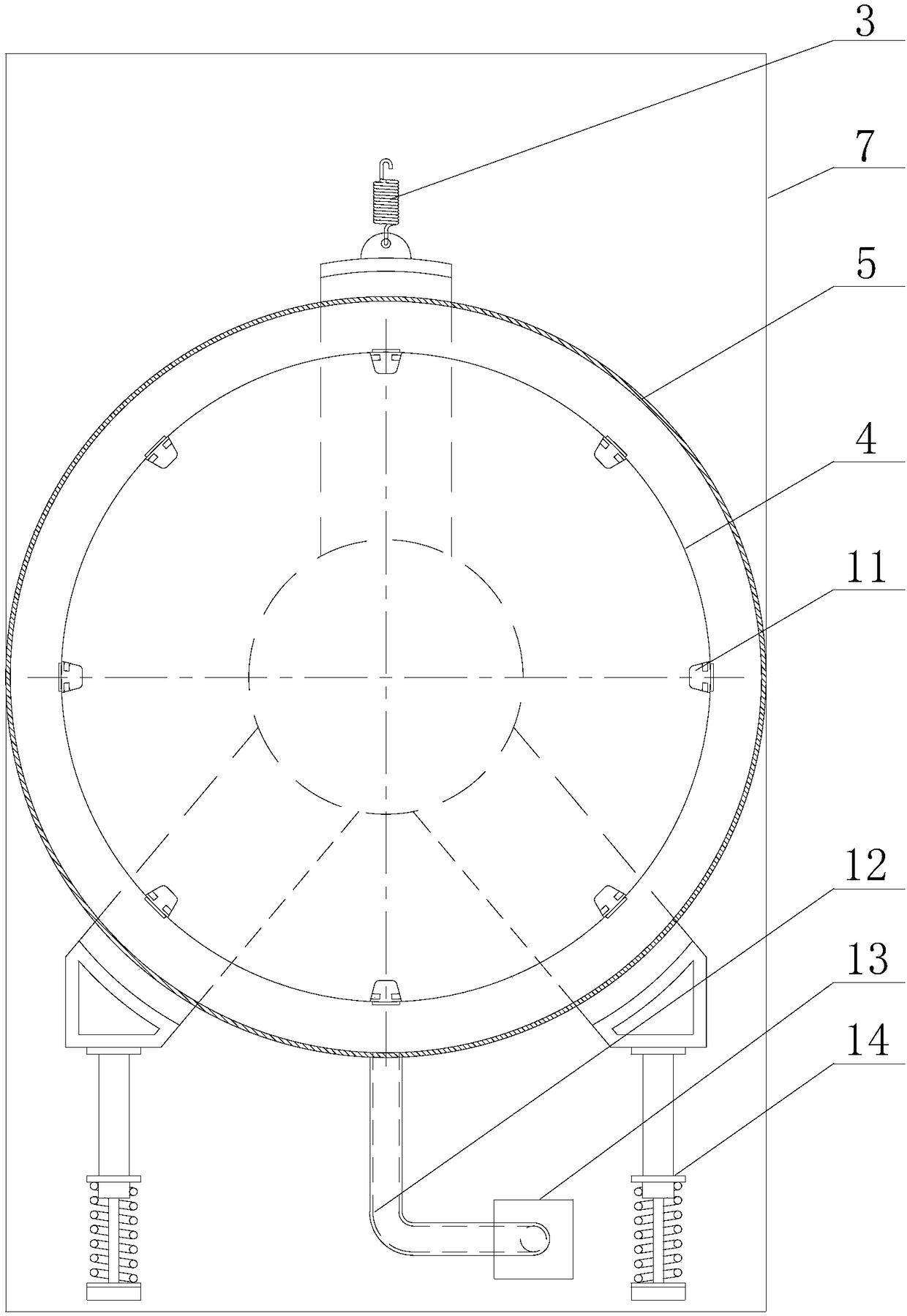

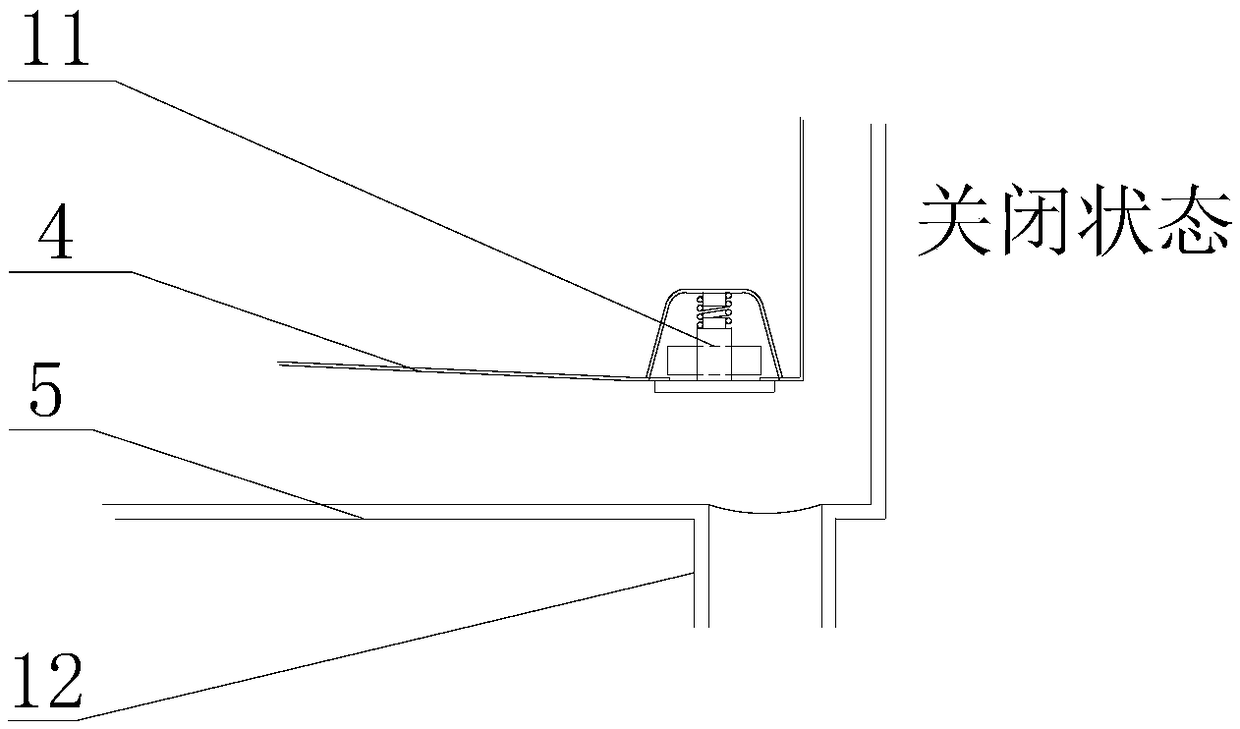

[0031] A kind of drum washing machine of the present invention is described in detail below in conjunction with accompanying drawing:

[0032] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a drum washing machine in this embodiment includes a body 7, a door body and an inner cylinder 4, the inner cylinder 4 is rotatably arranged in the body 7, and the inner cylinder 4 holds water during the washing process; the inner cylinder 4 The front portion of the cylinder 4 is provided with an opening for picking and placing clothes, and the door body can be opened / closed and installed on the front portion of the body 7 and corresponds to the insertion opening of the inner cylinder 4; The door body can be relatively rotatably sealed and connected.

[0033] The inner cylinder 4 of the drum washing machine of this embodiment is a non-porous inner cylinder without dehydration holes on the cylinder wall. During washing, the inner cylinder 4 contains washing water, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com