Construction method of semicircular caisson and pile foundation combination breakwater

A construction method and semi-circular technology, applied in breakwaters, caisson, infrastructure engineering, etc., can solve problems such as restricting application, increasing construction cost, destroying ecological environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

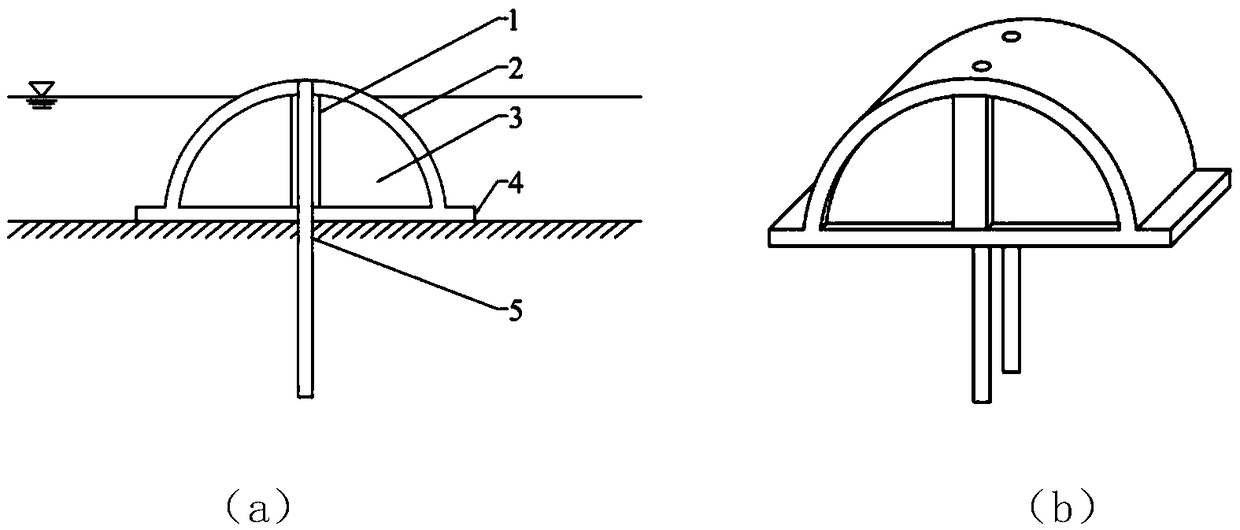

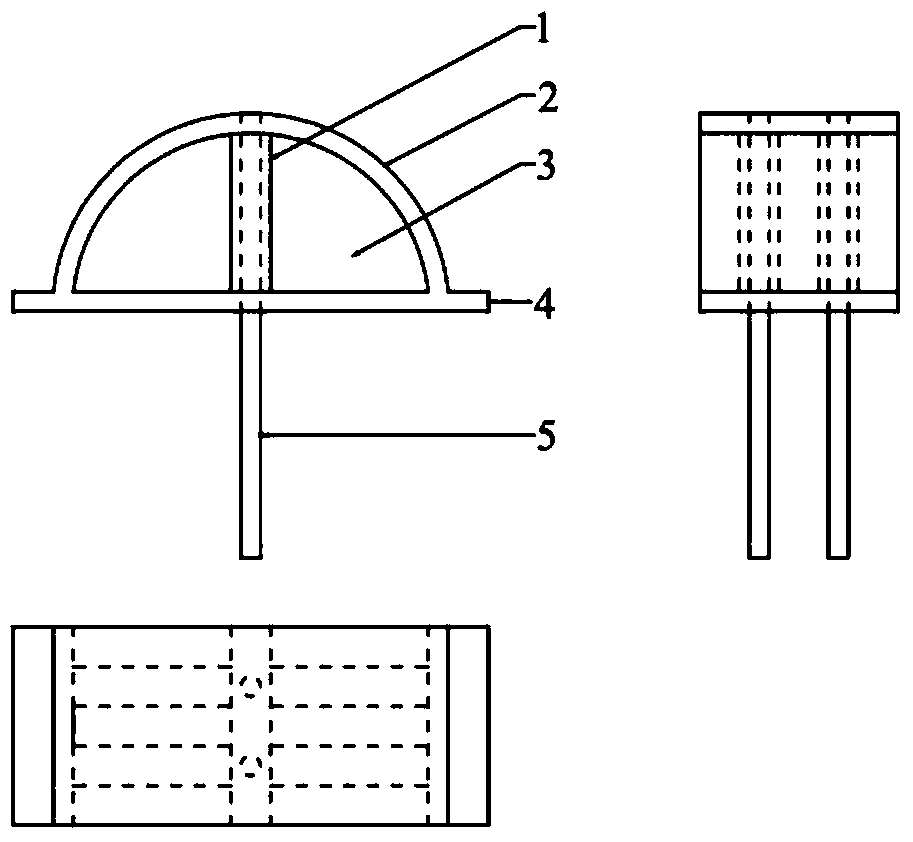

[0013] figure 1 It is the exterior view of a single set of semicircular caisson and pile foundation combined breakwater; figure 2 It is a structural diagram of a single set of semicircular caisson and pile foundation combined breakwater. figure 2 Among them, 1 is the vertical plate, 2 is the semicircular arch ring, 3 is the rib plate, 4 is the bottom plate, and 5 is the pile foundation, in which the semicircular arch ring can be appropriately opened as the sand filling hole of the semicircular caisson At the same time, when the semicircular caisson sinks, water can be injected through the opening to facilitate the semicircular caisson to sit on the bottom.

[0014] The main construction process of the semicircular caisson and pile foundation combined breakwater is as follows: firstly, using the combined steel formwork, it is poured step by step in the order of bottom plate 4, vertical plate 1, rib plate 3, and semicircular arch ring 2 in the precast yard Semi-circular cais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com