Viscous fluid damper with self-testing performance

A viscous fluid and damper technology, applied in the field of civil engineering structural vibration control devices, can solve the problems of difficulty in implementing non-destructive testing and disassembly experimental testing, inability to effectively detect the performance of viscous fluid dampers, and time-consuming and laborious disassembly experimental testing. To ensure long-term effectiveness, reduce vibration, non-destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

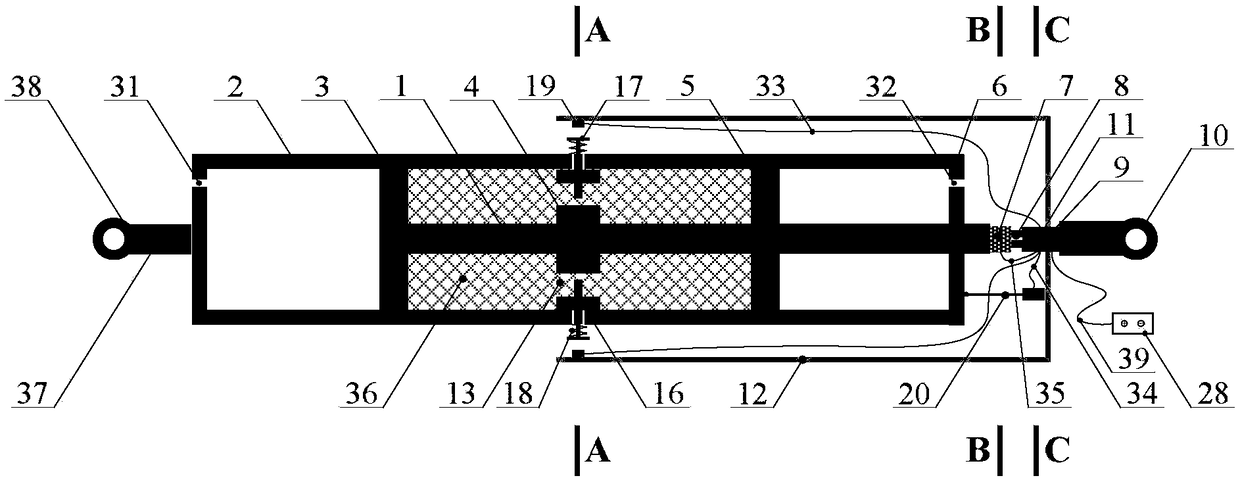

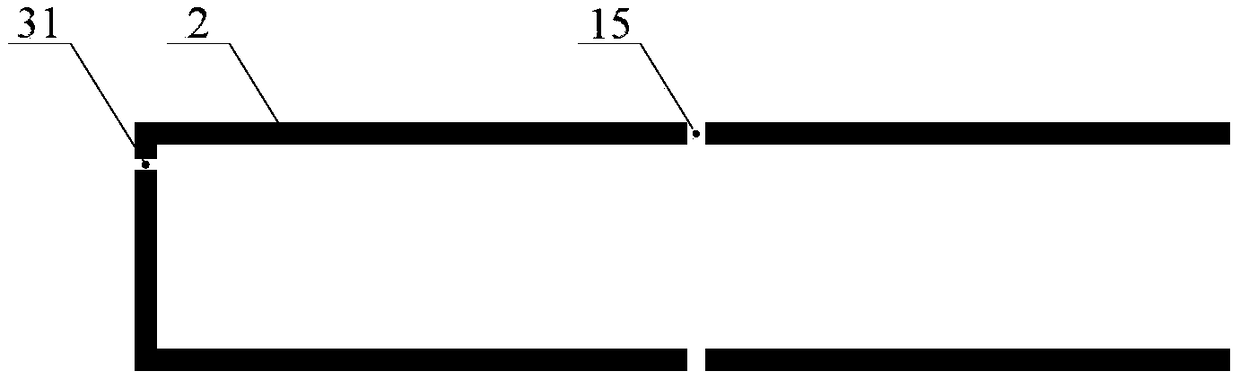

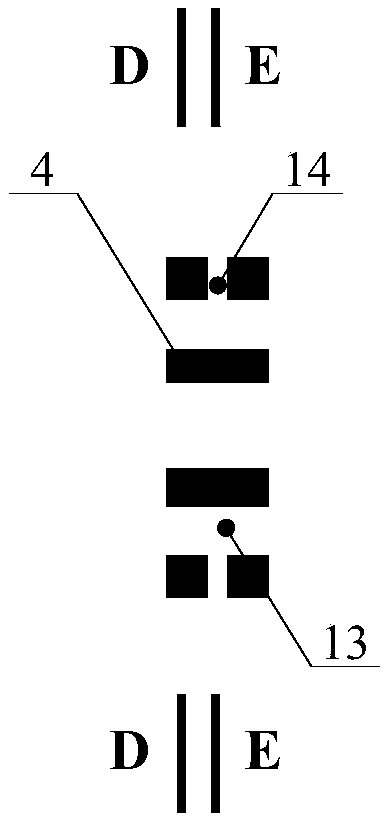

[0020] Such as Figure 1-8 As shown, the left end of the cylinder body 2 is fixedly connected with the first connecting earring 38 through the connecting rod 37, the end plate of the cylinder body 2 is provided with a first vent hole 31, the cover plate 6 is provided with a second vent hole 32, and the guide rod 1 One end passes through the second piston 5, the partition plate 4 and the first piston 3 in turn, and is placed inside the cylinder body 2; Slide; the other end of the guide rod 1 passes through the cover plate 6, and is fixedly connected with the force sensor 7, the transmission rod 8, the stepper motor 9 and the second connecting earring 10 in turn; the cover plate 6 is provided with a second vent hole 32; A cylindrical protective cover 12 is fixed on the outside of the stepper motor 9, and a temperature sensor 11 and a performance self-test system are integrated inside; the stepper motor 9 is connected to the uninterruptible power supply 28 through the stepper mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com