Intercooling pipeline, cooling system, automobile and cooling method of intercooling pipeline

A heat dissipation system and cold pipe technology, which is applied in the fields of intercooler pipelines, heat dissipation systems, automobiles and intercooler pipelines. The effect of multiple constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

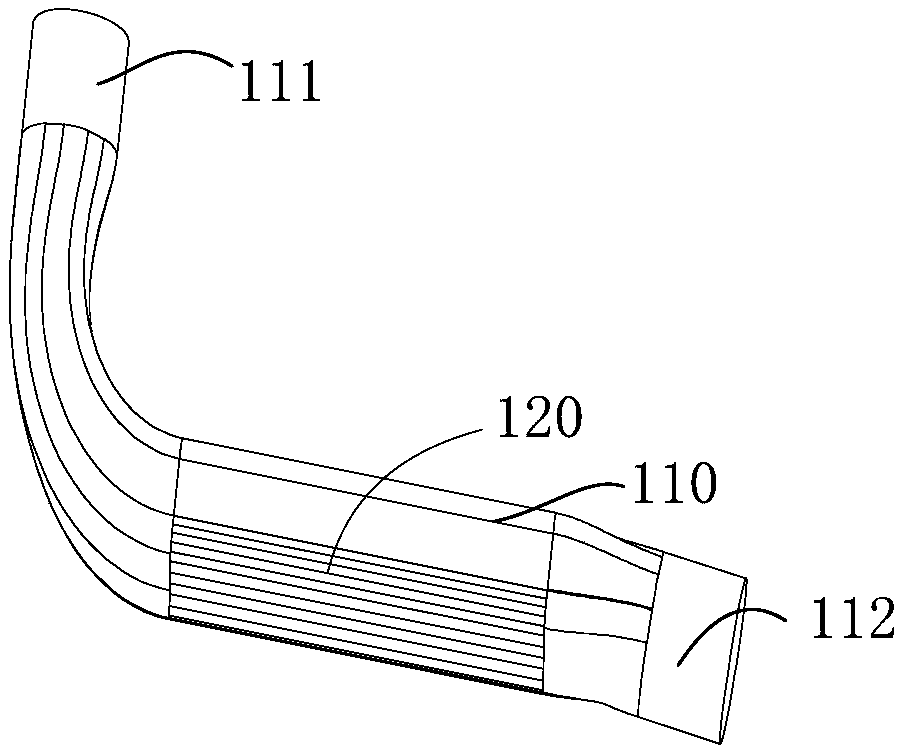

[0047] This example provides an intercooler pipeline, please refer to figure 1 , figure 1 The isometric view of the intercooling pipeline provided by the embodiment of the present invention. It includes a pipeline main body 110 and a heat dissipation structure 120 arranged on the pipeline main body 110,

[0048] The pipeline body 110 includes an inlet port 111 and an outlet port 112 , the inlet port 111 communicates with the air outlet of the turbocharger 630 , and the outlet port 112 communicates with the air inlet of the intercooler 200 .

[0049]The high-temperature gas output by the turbocharger 630 flows to the intercooling pipeline 100, and the external air directly acts on the intercooling pipeline 100. The heat dissipation structure 120 exchanges heat between the high-temperature gas and the external air, and passes through the intercooling pipeline 100 to dissipate heat in the first stage. Afterwards, it flows to the intercooler 200 , and then flows to the air intak...

Embodiment 2

[0061] This embodiment is another preferred solution paralleled with Embodiment 1. The technical solution disclosed in Embodiment 1 outside the distinguishing technical features belongs to the scope disclosed in this embodiment. Embodiment 1 outside the distinguishing technical features The disclosed technical solutions will not be described repeatedly.

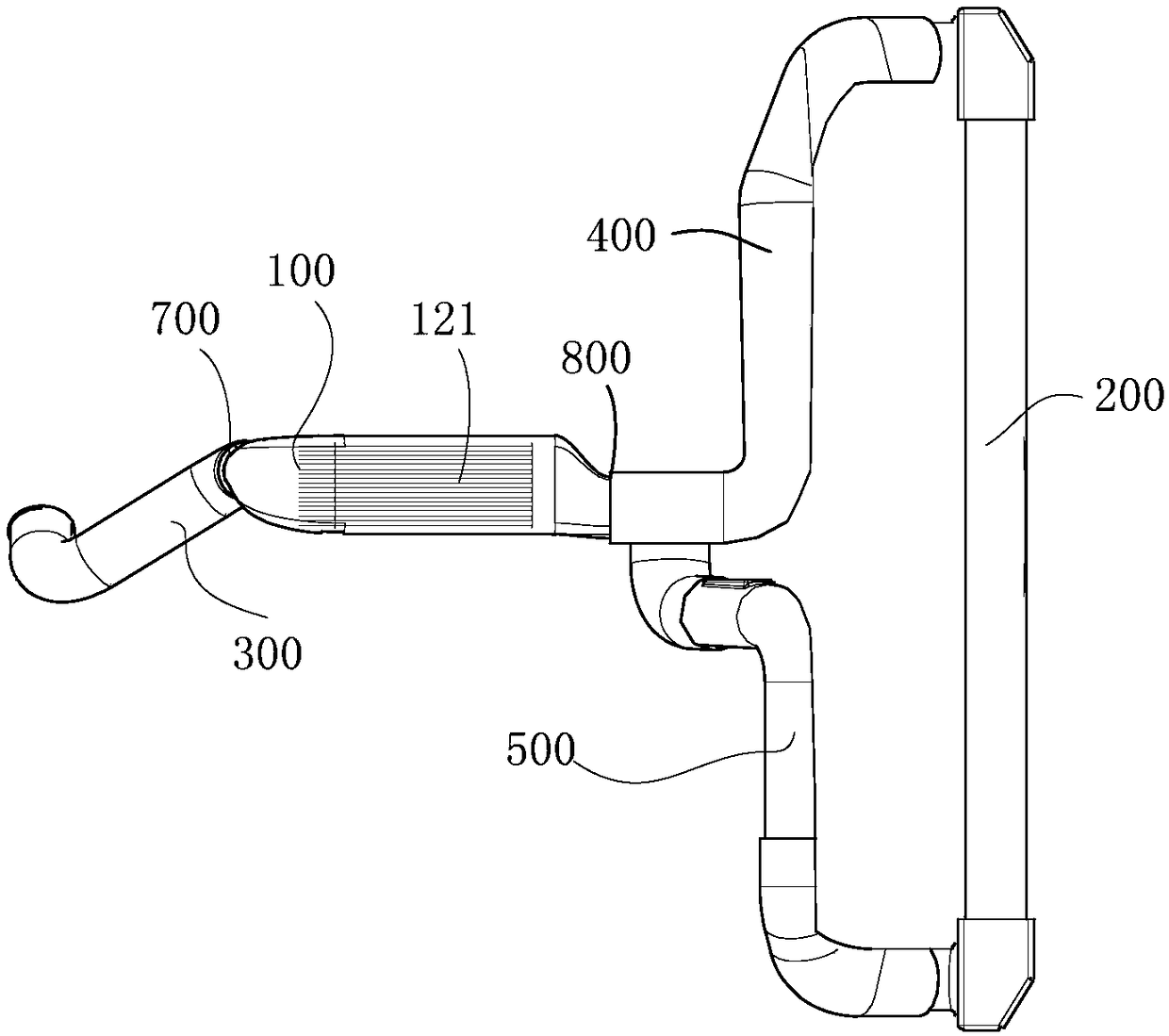

[0062] This embodiment provides a cooling system, please refer to Figure 1 to Figure 2 , figure 1 An axonometric view of the intercooling pipeline provided for the embodiment of the present invention; figure 2 The bottom view of the heat dissipation system provided by the embodiment of the present invention includes an intercooler pipeline 100 .

[0063] The high-temperature gas output by the turbocharger 630 flows to the intercooler pipeline 100, the outside air directly acts on the intercooler pipeline 100, passes through the intercooler pipeline 100 to dissipate heat, and then flows to the intercooler 200, and then pas...

Embodiment 3

[0071] This embodiment is another preferred solution juxtaposed with Embodiment 1 to Embodiment 2. The technical solutions disclosed in Embodiment 1 to Embodiment 2 other than distinguishing technical features belong to the scope disclosed in this embodiment. The technical solutions disclosed in Embodiment 1 to Embodiment 2 other than the technical features will not be described again.

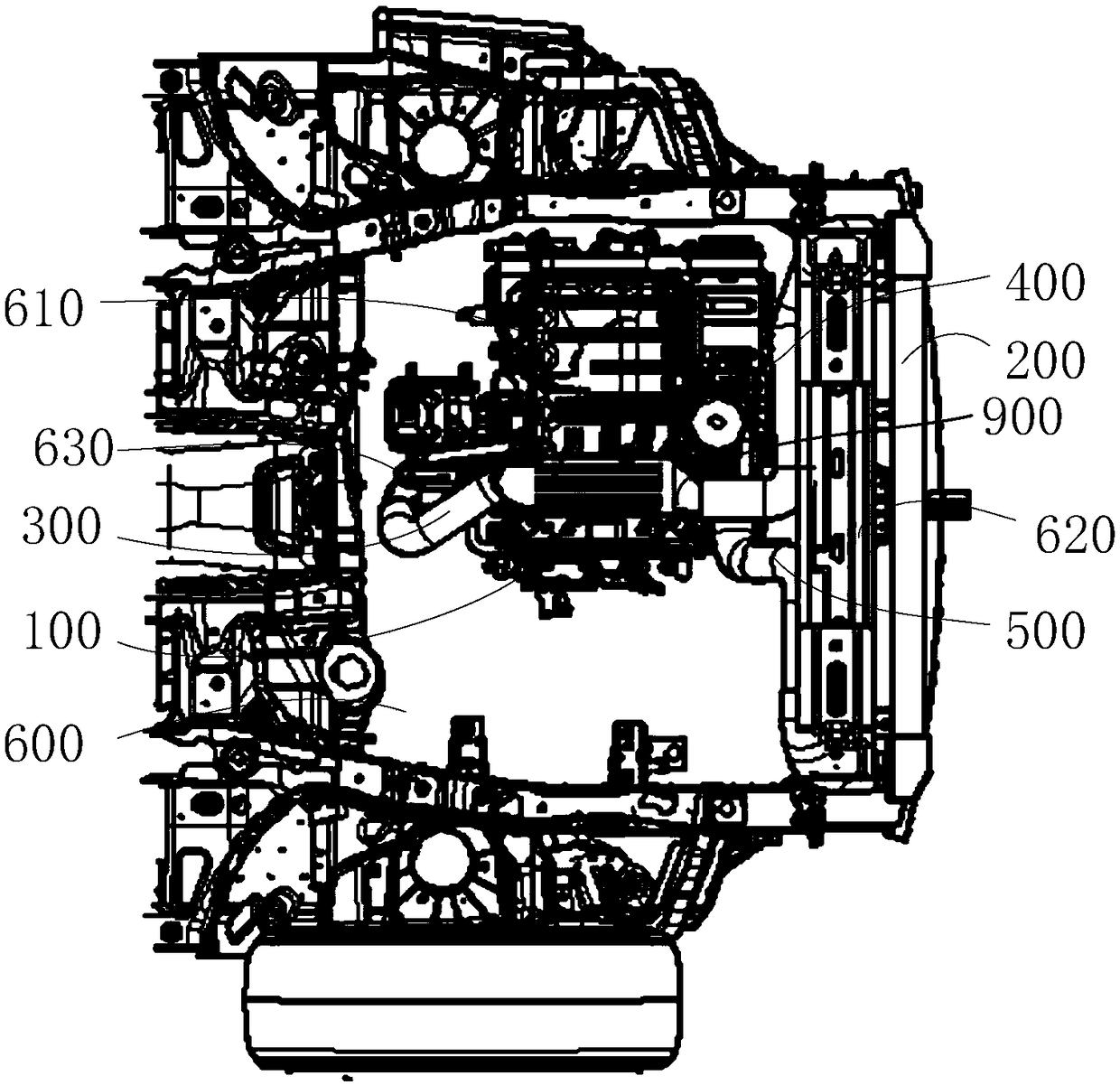

[0072] This embodiment provides a car, please refer to Figure 1 to Figure 3 , figure 1 An axonometric view of the intercooling pipeline provided for the embodiment of the present invention; figure 2 The bottom view of the cooling system provided for the embodiment of the present invention; image 3 The bottom view of the engine compartment in the car provided by the embodiment of the present invention. Including cooling system and engine compartment 600.

[0073] An engine 610, a bumper 620 and a turbocharger 630 are arranged in the engine compartment 600; the intercooler pipeline 100 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com