Model-based manufacturing execution management system and method

A manufacturing execution and management system technology, applied in the field of enterprise management, can solve problems such as dynamic construction of station capacity, uncertain process path, and unstable personnel, so as to enhance the market competitiveness of enterprises, make the operation process transparent, and reduce excessive dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

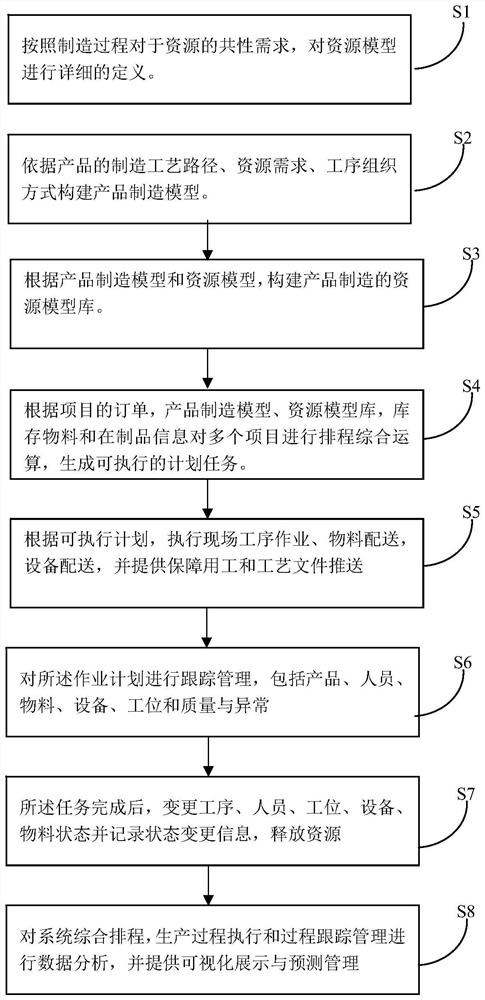

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

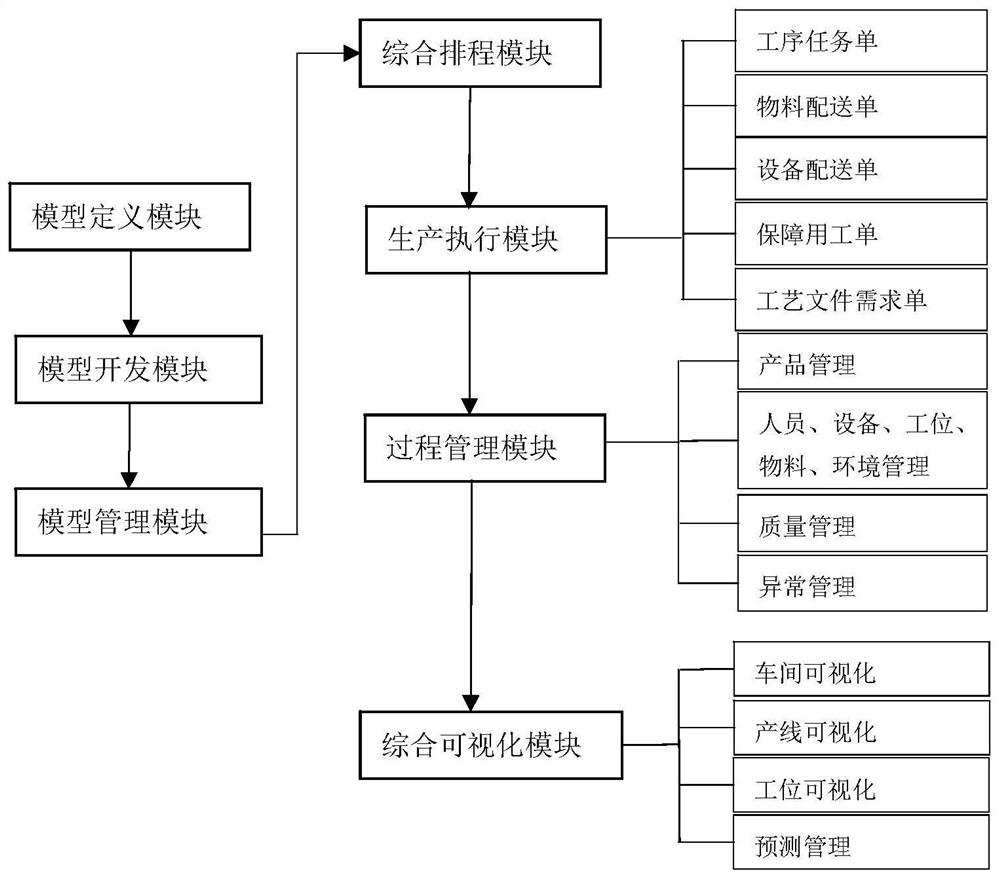

[0039] An embodiment of the present invention provides a model-based manufacturing execution management system, such as figure 1 As shown, it includes model definition module, model development module, model management module, comprehensive scheduling module, production execution module, process management module and comprehensive visualization module.

[0040] Wherein, the model definition module is used to formulate basic resource models and feature definitions such as personnel, equipment, materials, process documents, and workstations, as well as product manufacturing models and feature definitions.

[0041] Wherein, the model development module constructs a model library according to the model specified by the model definition module and the corresponding feature definitions of each model, specifically including a product manufacturing model library, a personnel m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com