Tunnel type drying oven

A drying oven and tunnel-type technology, which is applied in the field of tunnel-type drying ovens, can solve the problems of dust generation in the transmission system, increase production costs, and dust generation, and achieve the effects of stable structure, energy saving, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

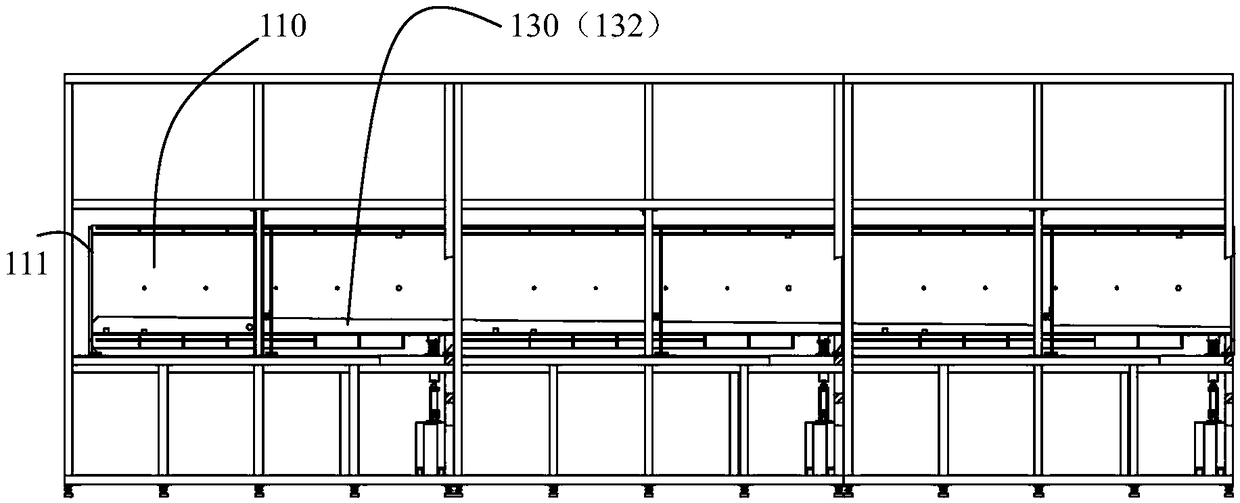

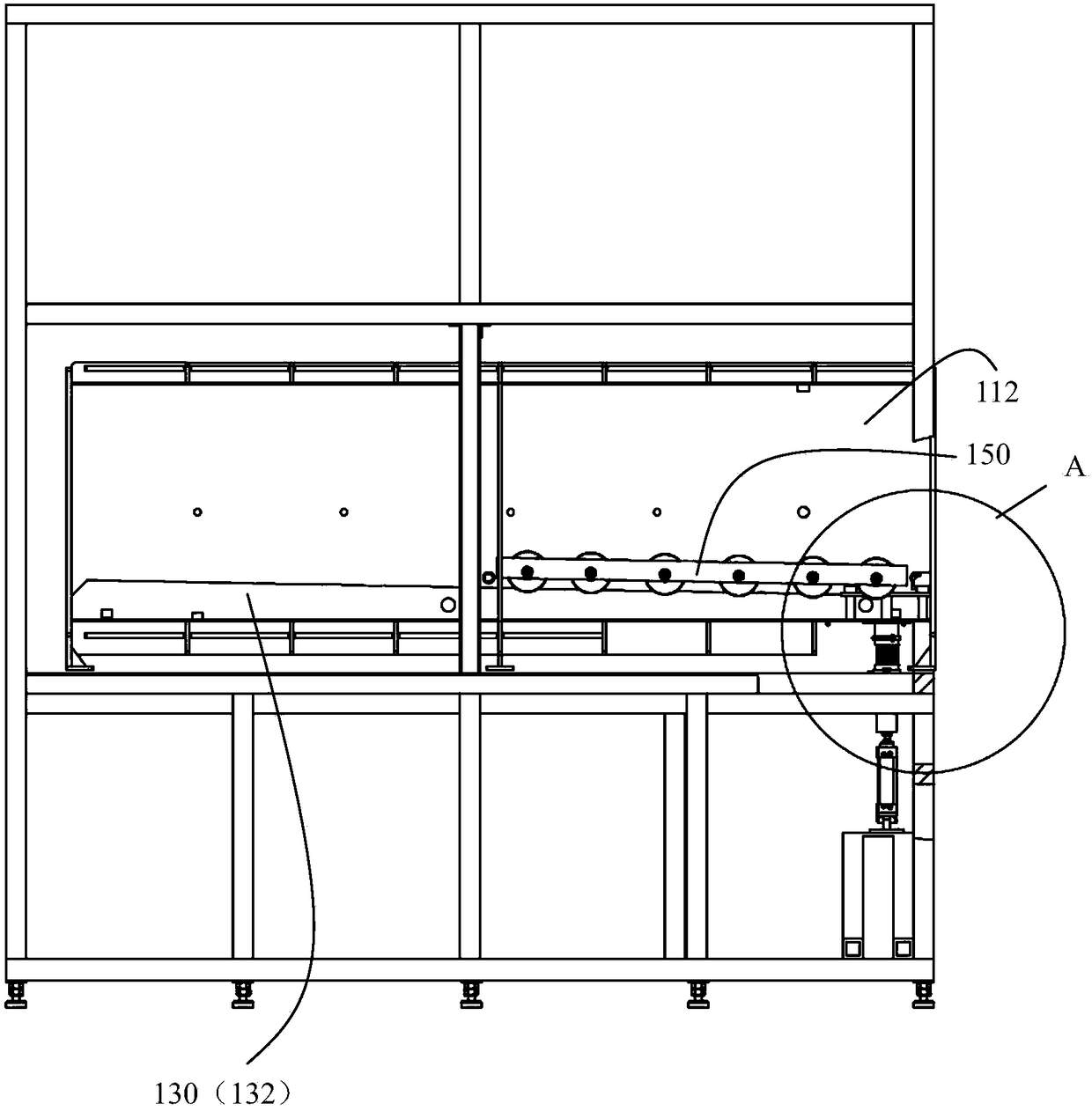

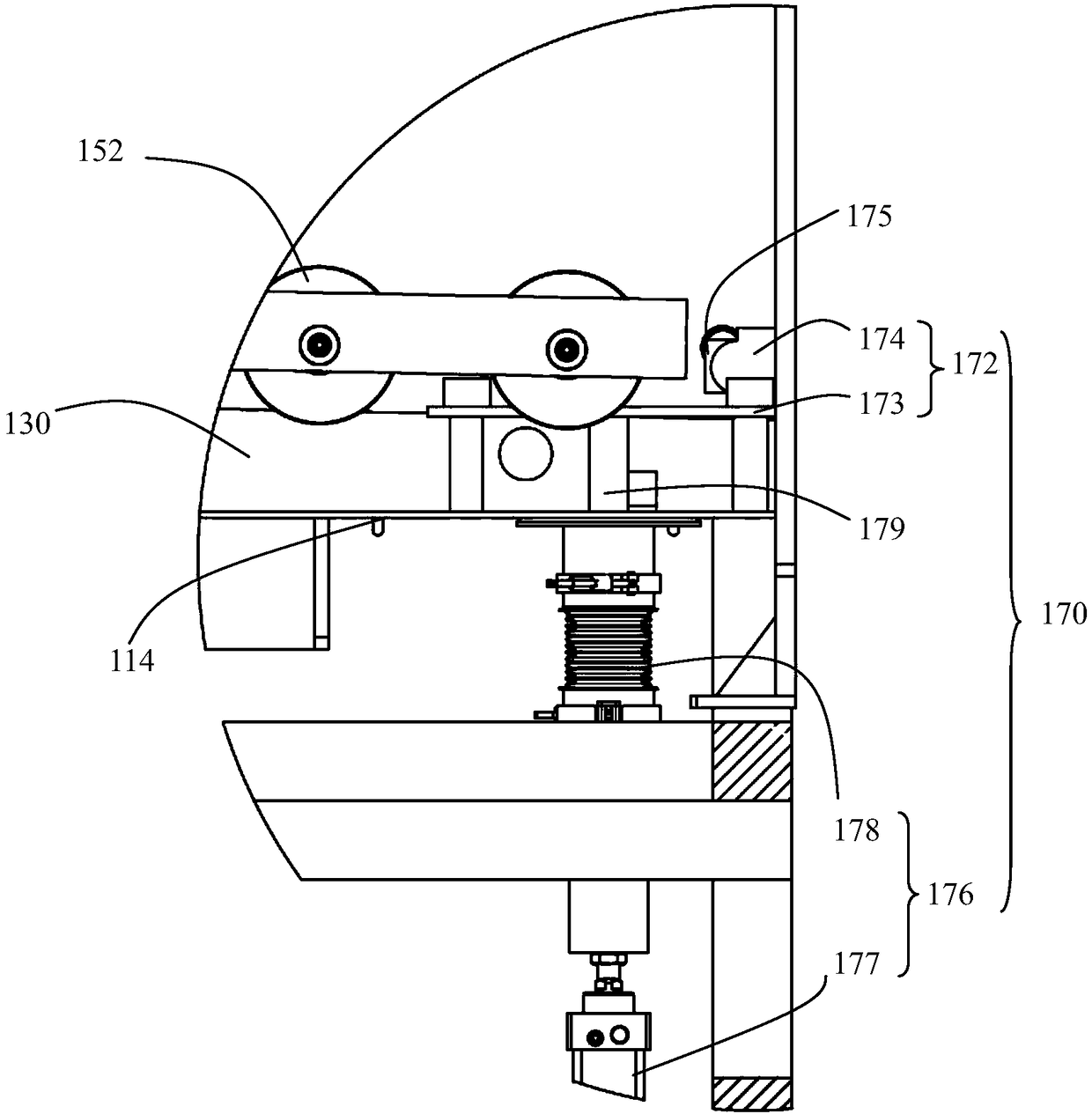

[0028] refer to Figure 1-Figure 3 , The first embodiment of the present invention provides a tunnel-type drying furnace, which mainly includes: a furnace body 110 , a guide rail 130 , and a transfer vehicle 150 . Body of furnace 110 comprises 3 furnace chambers 112 connected in sequence, all furnace chambers 112 are connected, and the inside of whole body of furnace 110 is an airtight cavity, promptly is provided with movable airtight door 111 at the head end and tail end of body of furnace, for Drying requires that the cavity be a vacuum or a near-vacuum cavity. In this embodiment, a movable airtight door (not shown in the figure) is also provided between adjacent furnace chambers 112 to ensure sufficient vacuum in each furnace chamber 112 . The furnace body 110 includes a bottom plate 114 , and the guide rail 130 is installed on the bottom plate 114 in this embodiment.

[0029] The guide rail 130 is laid inside the furnace body 110, and the guide rail 130 is inclined at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com