Intelligent sensitization adjusting system and method

A technology of adjusting system and adjusting method, which is applied in blasting and other directions, can solve the problems of low adjustment efficiency and inability to accurately adjust the flow of sensitizer, and achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

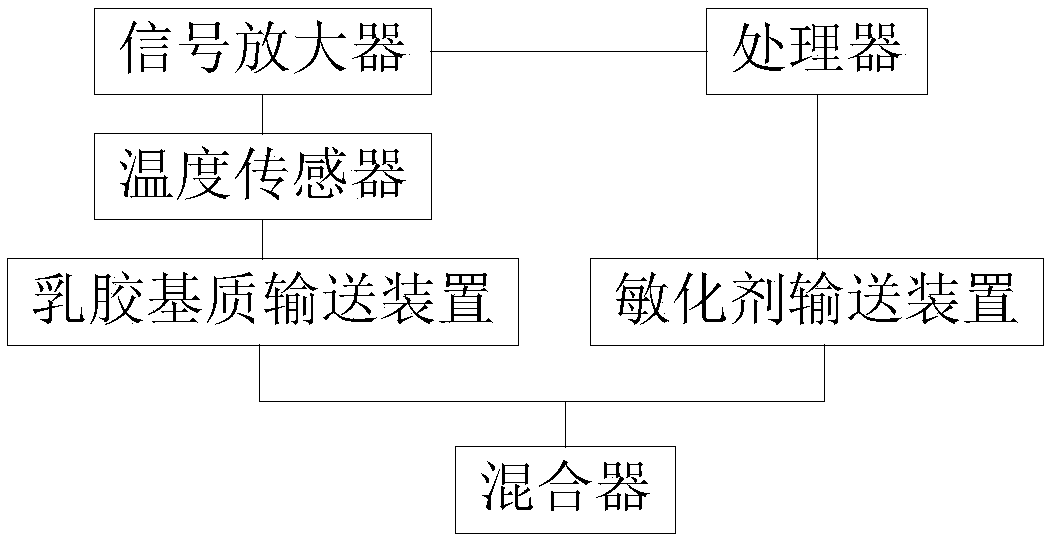

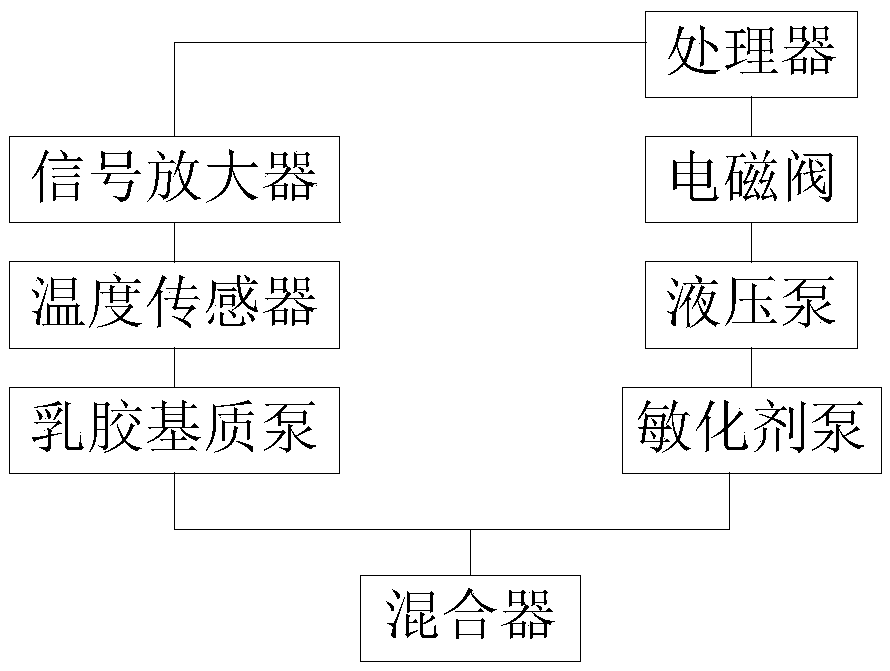

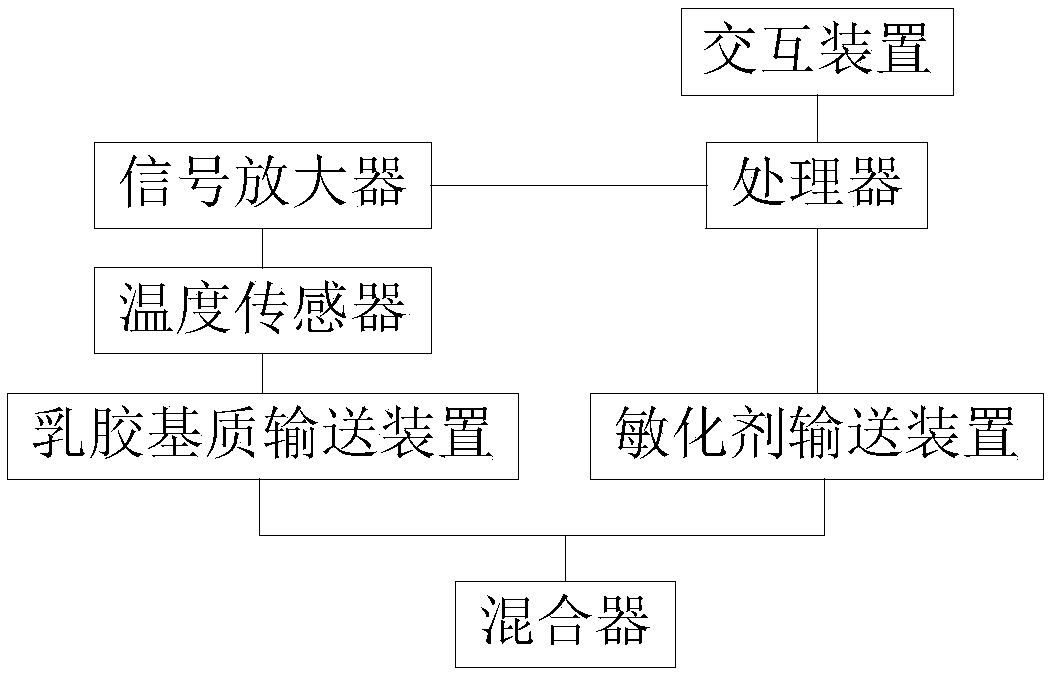

[0050] figure 1 A structural block diagram of an intelligent sensitization adjustment system provided by an embodiment of the present invention, the system is applied to an on-site mixing vehicle, and the on-site mixing vehicle includes a latex matrix conveying device for conveying latex matrix, a Sensitizer delivery devices for agents and mixers for mixing latex base and sensitizers, such as figure 1 As shown, the system includes: temperature sensor, signal amplifier and processor;

[0051] The temperature sensor is arranged on the latex matrix conveying device and is used to detect the temperature of the latex matrix, generate a temperature signal and send it to the signal amplifier for amplification;

[0052] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com