Automatic transmission gearshift quality test board rack and verification method thereof, and gearshift quality evaluation method

A technology for automatic transmission and shift quality, which is applied in the field of automatic transmission shift quality test bench and its calibration, which can solve the problems of reduced test cycle, long test time, and low precision, so as to reduce the test cycle and save the test time. Time, the effect of improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

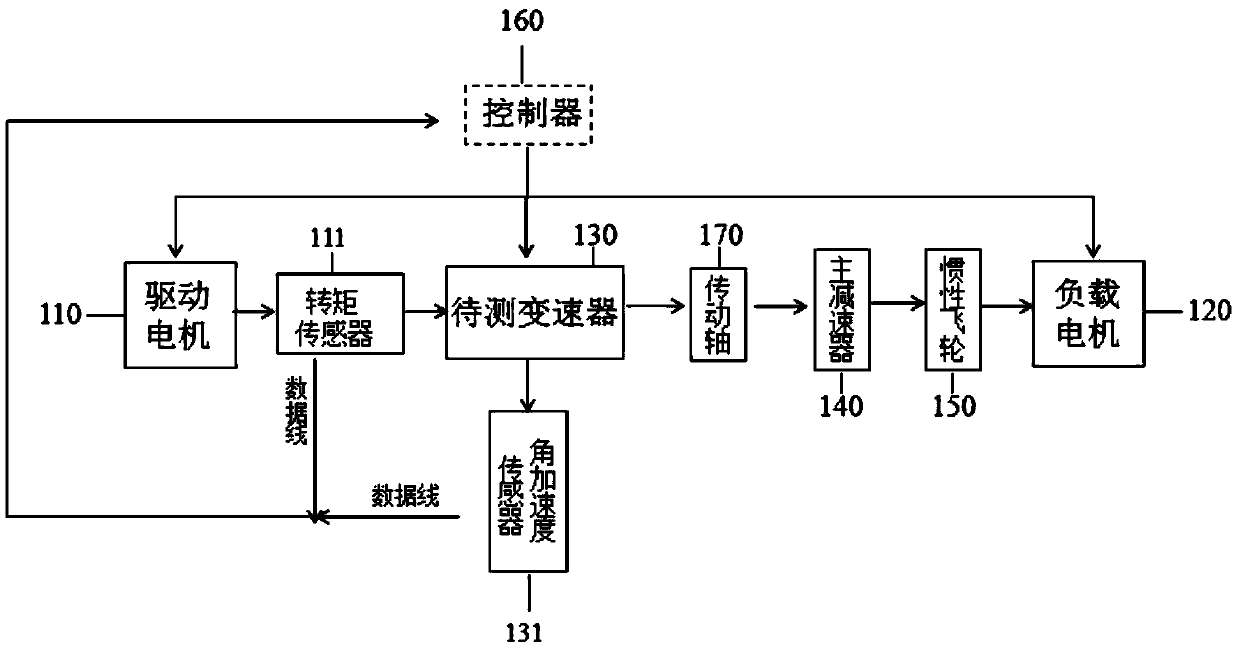

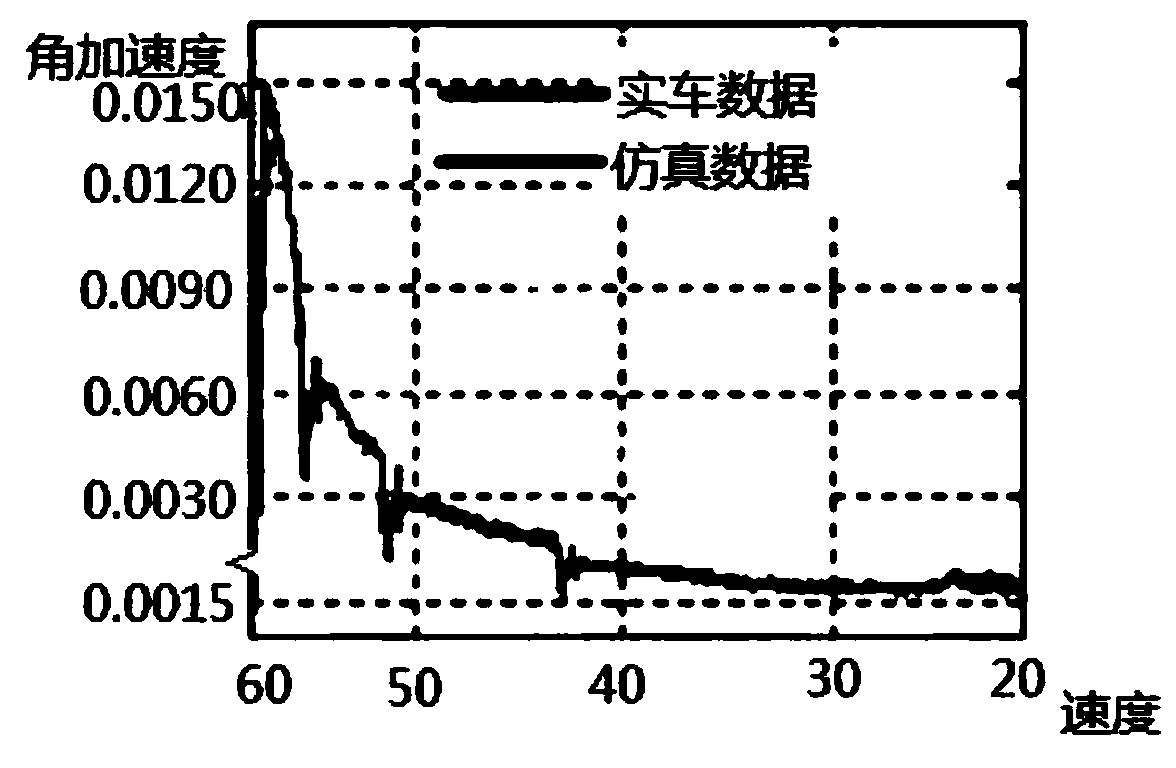

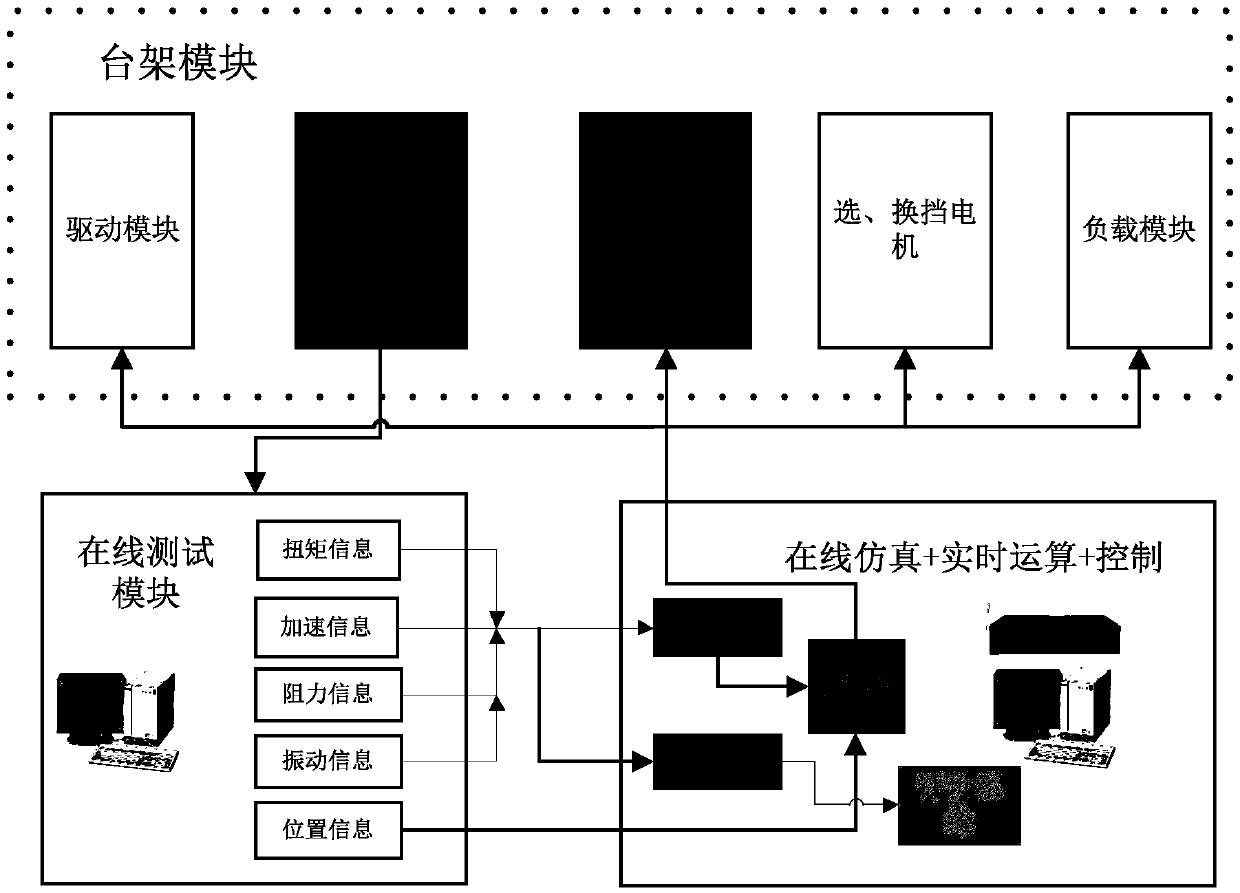

[0107] Step 1: Carry out the actual vehicle test first. After selecting the test vehicle, install a vehicle speed sensor on its output shaft (to measure the vehicle speed), install an acceleration sensor on the chassis (to measure the acceleration of the vehicle), and use bolts on the output shaft of the power motor A flange-type torque sensor is installed through the threaded hole on the flange (that is, to measure the input torque of the automatic transmission), and an angular acceleration sensor is installed on the output shaft of the automatic transmission (to measure the angular acceleration of the output shaft of the automatic transmission), and through sampling The circuit, after several times of digital filtering and data amplification, is input to the test host by the data acquisition card for data processing and data storage. The parameters of the car are shown in Table 1;

[0108] Table 1

[0109] vehicle weight

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com