Cover plate wear resistance test device

A test device and wear resistance technology, which is applied in the field of cover plate wear resistance test device, can solve the problems affecting the authenticity of test results and the reduction of positive pressure, etc., and achieve the effect of simple and practical device, stable pressure balance and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

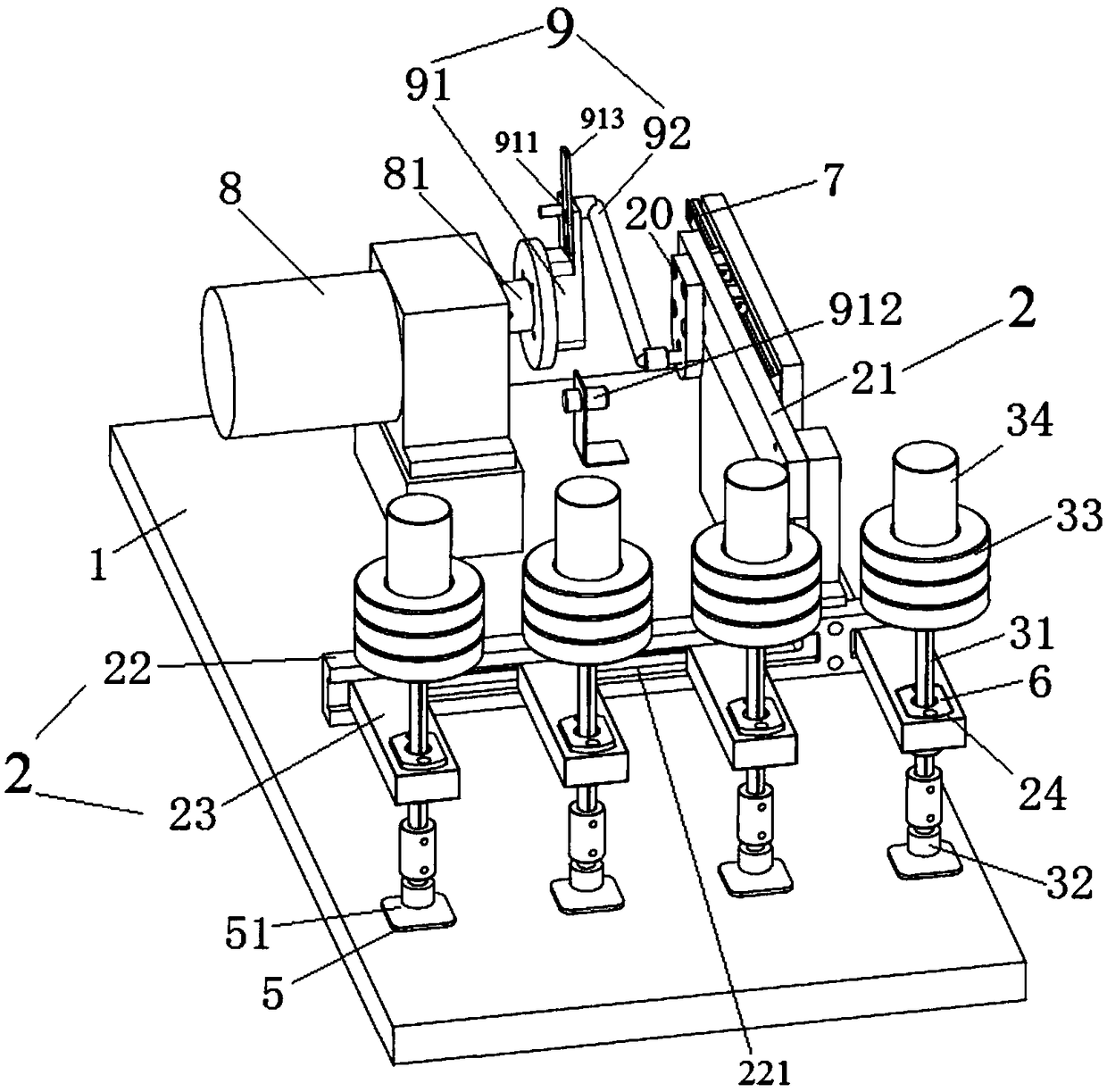

[0026] see figure 1 The test device for the wear resistance of the cover plate includes a bottom plate 1, a horizontal moving member 2 and a friction assembly 3 arranged on the bottom plate. The horizontal moving member can move back and forth along a straight track in the horizontal direction above the bottom plate, and the friction assembly is arranged on the horizontal moving member. Above, the friction assembly includes a vertical slide bar 31, a grinding head 32 and a counterweight 33, the length direction of the vertical slide bar is set along the vertical direction, the counterweight is pressed on the top of the vertical slide bar, and the grinding head is detachable Fixed at the bottom of the vertical slide bar, the end surface of the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com