A method for measuring the agglomeration degree of ferromagnetic powder in a suspension system

A measurement method, ferromagnetic technology, applied in the direction of nuclear magnetic resonance analysis, etc., can solve the problem of difficult comparison of dispersion effect, achieve the effect of improving production process and product performance, simple process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

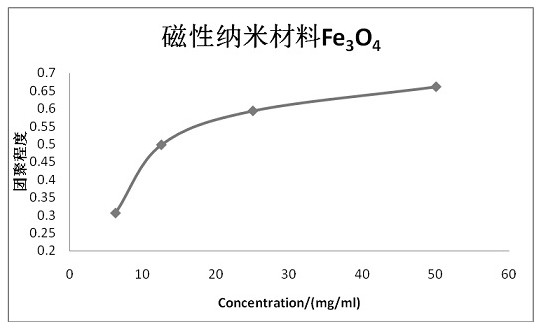

[0039] Method for determining the degree of ferromagnetic powder in a suspension system, including the following steps:

[0040] (1) The powder suspension solution of different solid content ω, the solute is ferromagnetic powder, the solvent is water;

[0041] (2) The solution prepared by the step (1) is separately diluted with pure water, and then the nucleate is measured by the nuclear magnetic resonance technique, respectively, and the Tricho Sample of different gradient concentration powder after the dilution is used. 2 Relaxation time and calculate the relaxation rate R 2 R 2f Where R 2 R 2f The relaxation rate of the powder particulate suspension system and the solvent, that is, respectively, respectively. 2 The reciprocal of the relaxation time; the powder suspension solution that finally derived different solid content is completely dispersed at the Ω 'value of the powder in completely dispersed, and Ω' is completely dispersed in the ideal state;

[0042] (3) Calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com