Coal bed gas separating system and process

A separation system, coalbed methane technology, applied in the petroleum industry, gas fuel, fuel and other directions, to avoid potential safety hazards, efficient removal, reaction mitigation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

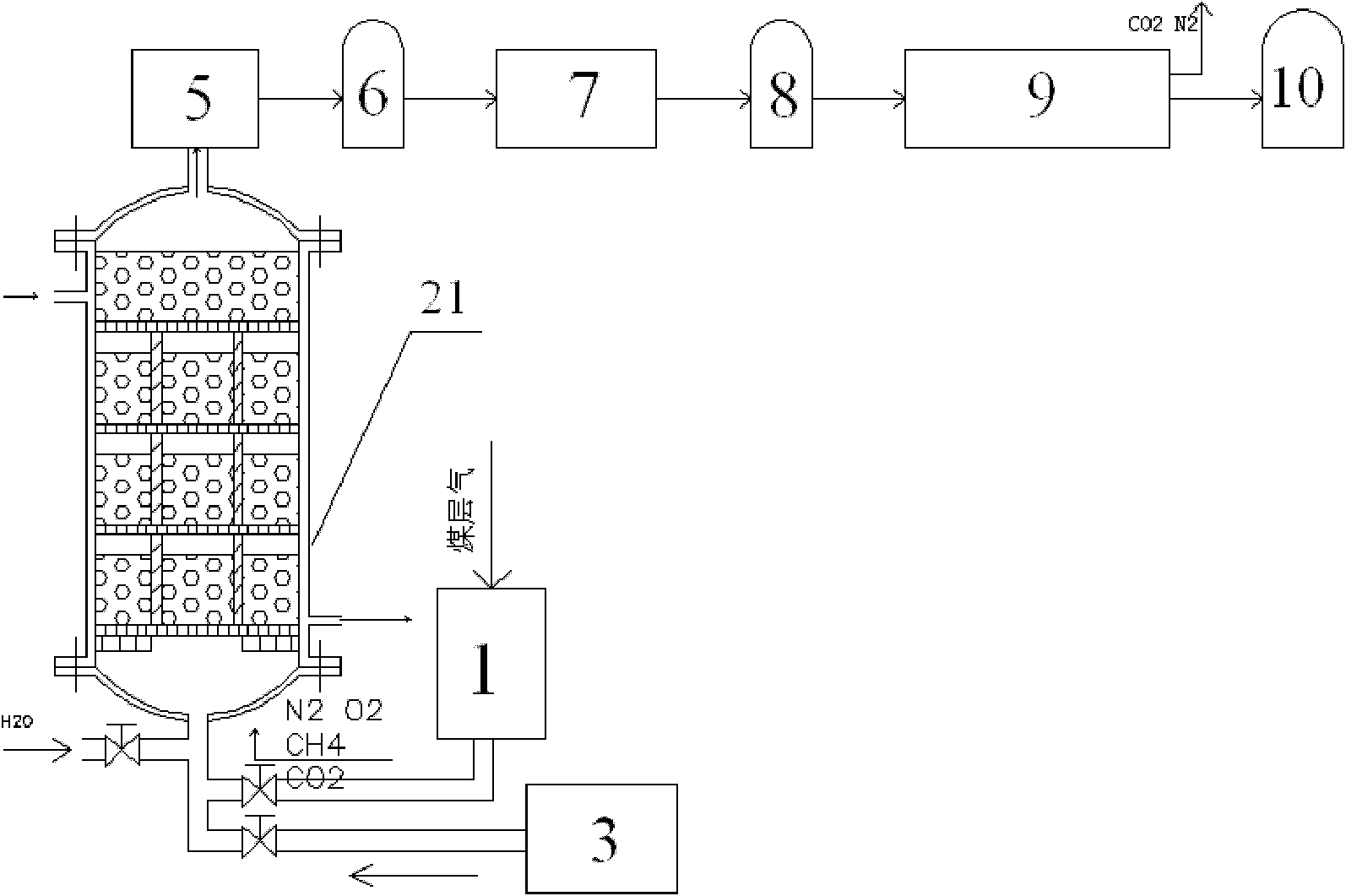

[0077] Such as figure 2 Shown, the system of coalbed methane separation of the present invention comprises compression purification device 1,0 2 Removal device, purification and degreasing device, CH 4 Separation system and product collection and delivery system;

[0078] The compression purification device 1 is used for pretreatment of the coalbed methane, and the compression purification device includes dust removal equipment, sulfur removal equipment and water removal equipment, and is used for pretreatment of the coalbed methane. The selected dust removal equipment is a water curtain or a return tank; the sulfur removal equipment is a dry alkaline catalyst filter tank or a wet copper sulfate washing tank; the water removal equipment is an organic silica gel adsorption and desorption tank. so that the coalbed methane only contains O 2 , N 2 、CH 4 and CO 2 Wait for gas.

[0079] The O 2 The removal device is used to remove the O contained in the purified coalbed met...

Embodiment 2

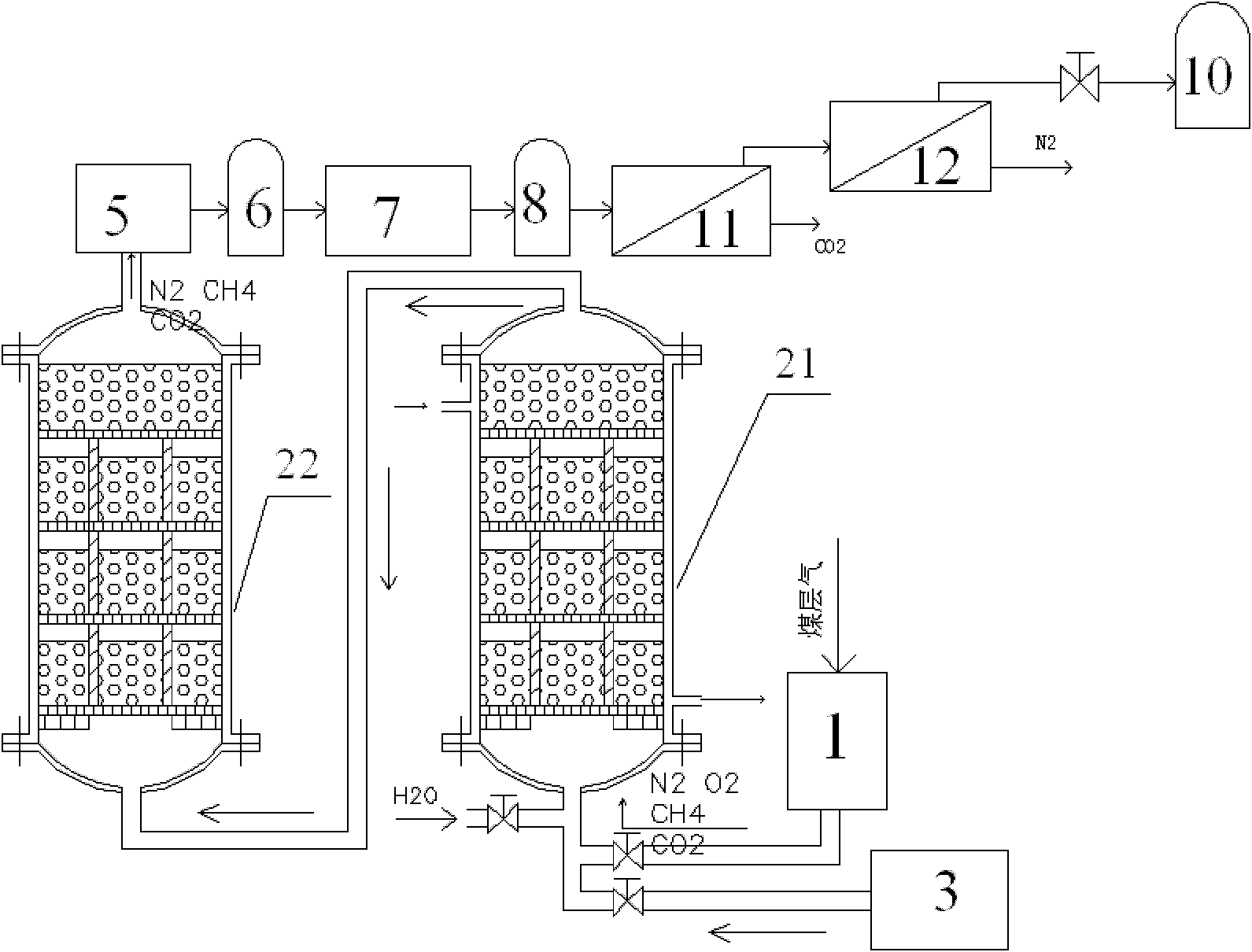

[0092] Such as image 3 Shown, the system of coalbed methane separation of the present invention comprises compression purification device 1,0 2 Removal device, purification and degreasing device, CH 4 Separation system and product collection and delivery system;

[0093] The compression purification device 1 is used for pretreatment of the coalbed methane, and the compression purification device includes dust removal equipment, sulfur removal equipment and water removal equipment, and is used for pretreatment of the coalbed methane. The selected dust removal equipment is a water curtain or a return tank; the sulfur removal equipment is a dry alkaline catalyst filter tank or a wet copper sulfate washing tank; the water removal equipment is an organic silica gel adsorption and desorption tank. so that the coalbed methane only contains O 2 , N 2 、CH 4 and CO 2 Wait for gas.

[0094] The O 2 The removal device is used to remove the O contained in the purified coalbed meth...

Embodiment 3

[0110] Such as Figure 4 Shown, the system of coalbed methane separation of the present invention comprises compression purification device 1,0 2 Removal device, purification and degreasing device, CH 4 Separation system and product collection and delivery system;

[0111] The compression purification device 1 is used for pretreatment of the coalbed methane, and the compression purification device 1 includes dust removal equipment, sulfur removal equipment and water removal equipment, and is used for pretreatment of the coalbed methane. The selected dust removal equipment is a water curtain or a return tank; the sulfur removal equipment is a dry alkaline catalyst filter tank or a wet copper sulfate washing tank; the water removal equipment is an organic silica gel adsorption and desorption tank. so that the coalbed methane only contains O 2 , N 2 、CH 4 and CO 2 Wait for gas.

[0112] The O 2 The removal device is used to remove the O contained in the purified coalbed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com