Current-type sulfuretted hydrogen sensor using Pt-Rh/C as sensitive electrode and preparation method thereof

A hydrogen sulfide sensor and sensitive electrode technology, which is used in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve the problems such as the inability to meet the requirements of real-time monitoring of hydrogen sulfide, the large size of large-scale analytical instruments, and the complicated operation. The effect of zero power consumption, lower detection limit and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

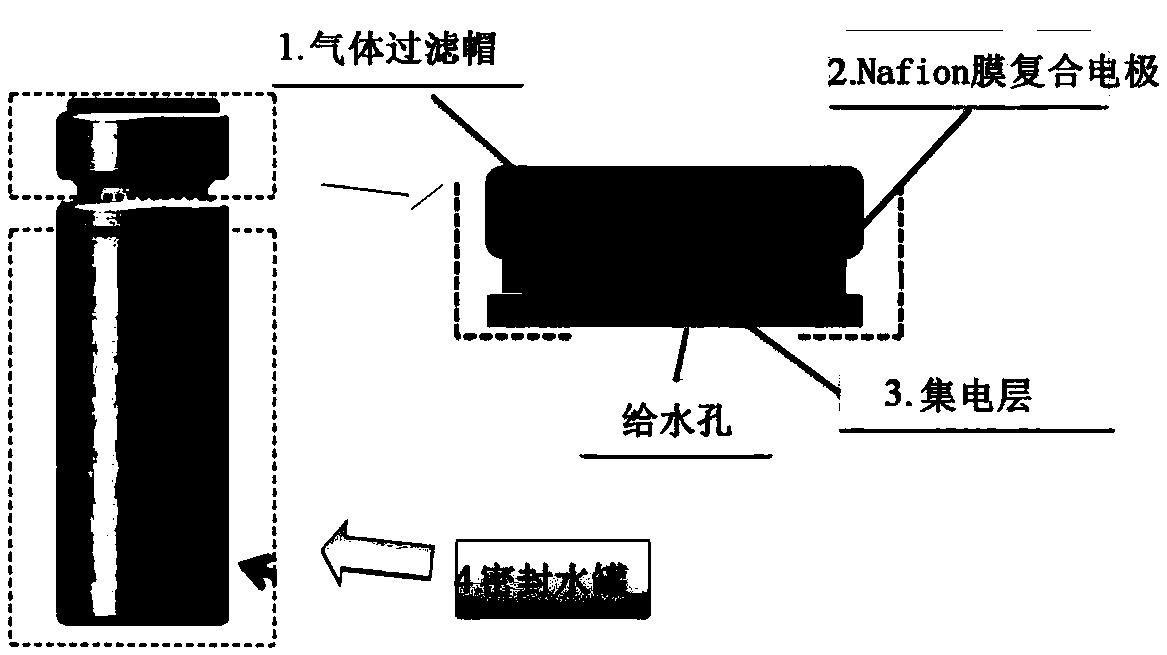

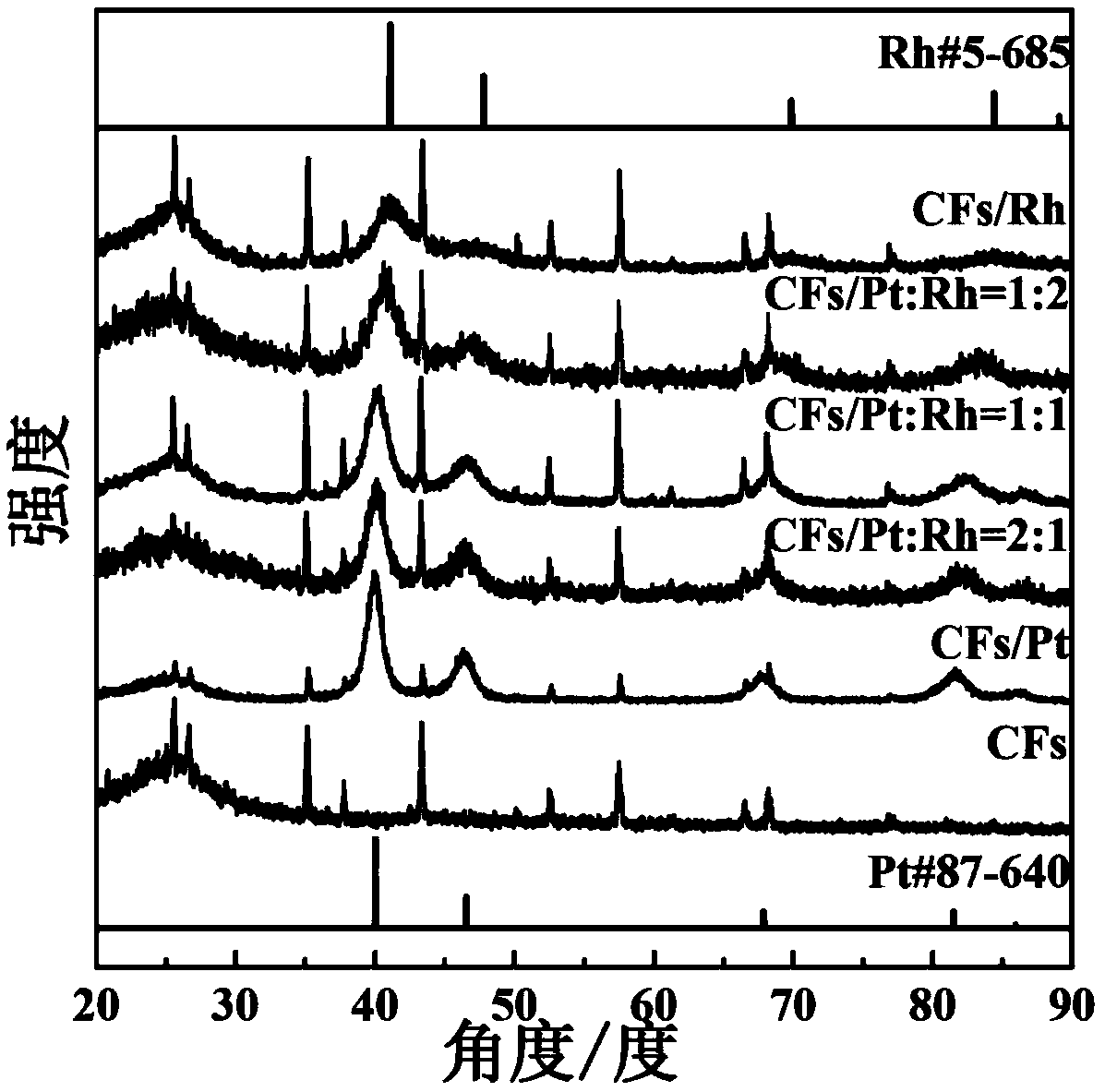

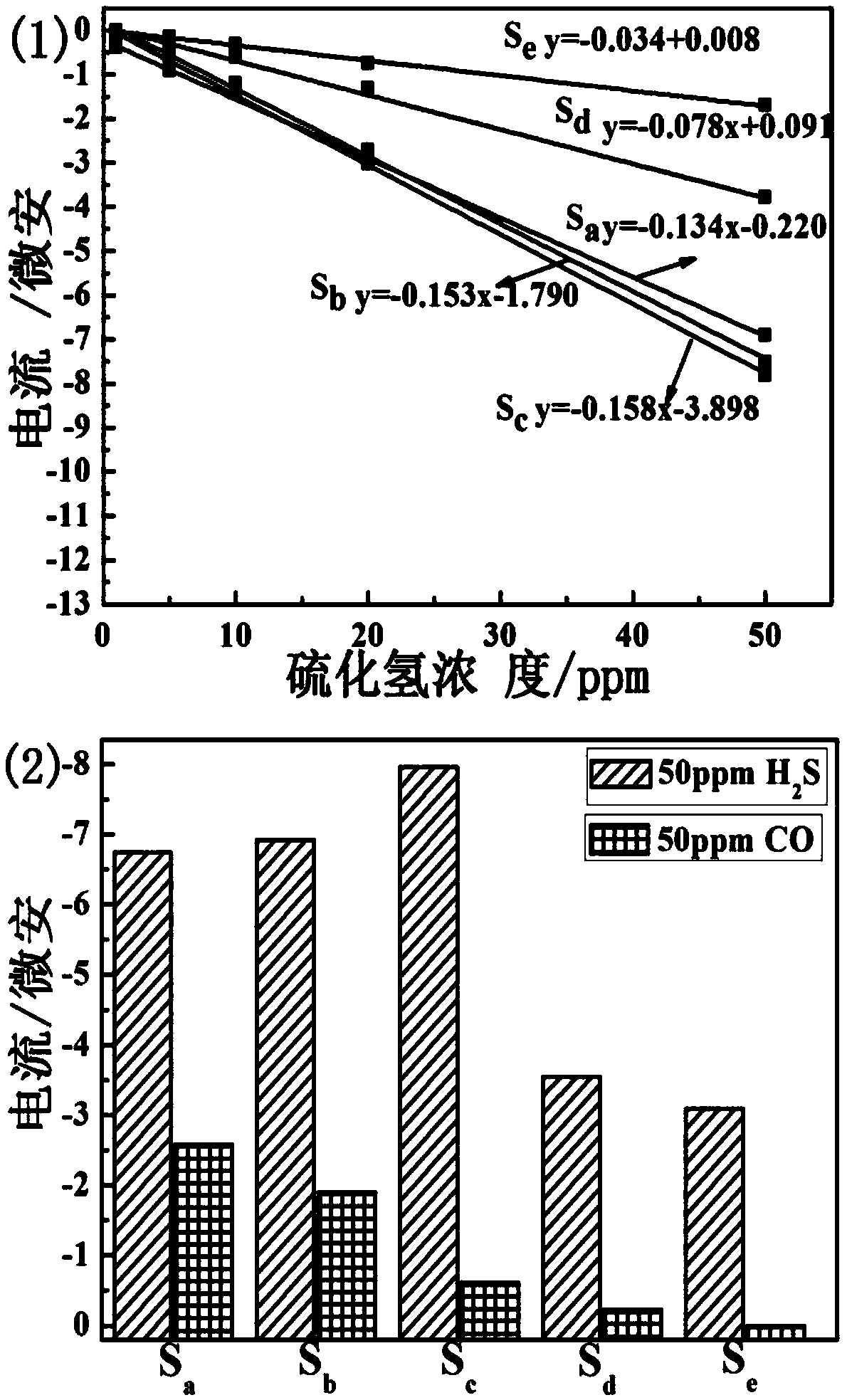

[0055] The Pt-Rh sensitive electrode material supported by carbon fiber was prepared by liquid phase reduction method, and the sensitive electrode material was hot-pressed on both sides of Nafion membrane to form a membrane electrode, and finally assembled to form a Nafion-based current-type hydrogen sulfide sensor. Its specific production process:

[0056] 1. Preparation of Pt-Rh / C sensitive electrode materials by liquid phase reduction method

[0057] Specific material preparation process:

[0058] (1) Weigh 0.4g carbon fiber powder into a beaker, add 10.26mL, 50mmol / L H 2 PtCl 6 solution, so that the mass ratio of carbon fiber and Pt is 4:1;

[0059] (2) Add 0.3 g of trisodium citrate as a stabilizer to the beaker of (1), wherein the mass ratio of Pt to trisodium citrate is 1:3, add deionized water, and prepare 50 mL of suspension;

[0060] (3) Put the prepared suspension into an ultrasonic cleaner for ultrasonic treatment for 30 minutes to make it evenly dispersed;

...

Embodiment 2

[0079] Prepare a sensitive electrode material with Pt:Rh=2:1, weigh the medicine according to the ratio shown in Table 1, and make the sensor as in Example 1. The difference from Example 1 is that sensitive electrode materials with different weight ratios of Pt and Rh are used, and the rest of the preparation conditions remain the same.

Embodiment 3

[0081] Prepare a sensitive electrode material with Pt:Rh=1:1, weigh the medicine according to the ratio shown in Table 1, and make the sensor as in Example 1. The difference from Example 1 is that sensitive electrode materials with different weight ratios of Pt and Rh are used, and the rest of the preparation conditions remain the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com