Boiler characteristic calibration method based on operating data

A technology of operation data and calibration method, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of deviation of characteristic design data, uncertainty of model accuracy, and inconsistency between simulation model characteristics and actual characteristics, etc. Achieve the effect of overcoming uncertainty and improving simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment and working process of the present invention will be further described below.

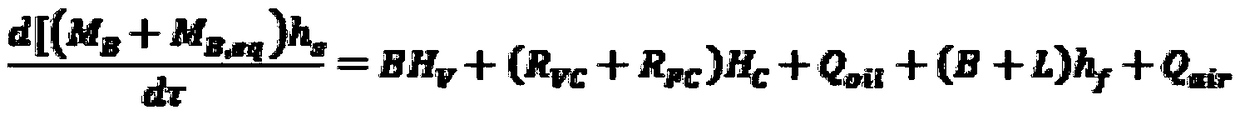

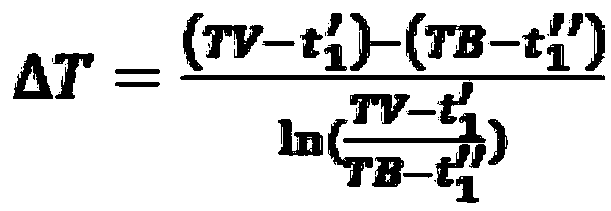

[0020] The boiler characteristic calibration method based on operation data involved in the present invention, the calibration method includes constructing a boiler system steady-state model, determining a minimum measurement variable parameter set, data collection, data preprocessing, and calibration calculation.

[0021] Determine the minimum measurement variable parameter set: through boiler operation analysis, construct a boiler system steady-state model including the relationship between material balance and energy balance; and through steady-state model verification, screen out measurable variables and design operations that can complete the calculation of boiler operating characteristics The process is to determine the minimum set of measured variable parameters that can complete the calculation of the boiler operating characteristics.

[0022] In this process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com