Method and furnace installation for heat treating metal strip

A technology for metal strips and heating furnaces, applied in heat treatment equipment, lighting and heating equipment, heat treatment furnaces, etc., can solve the problems of short residence time of internal oxidation and adverse effects on product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

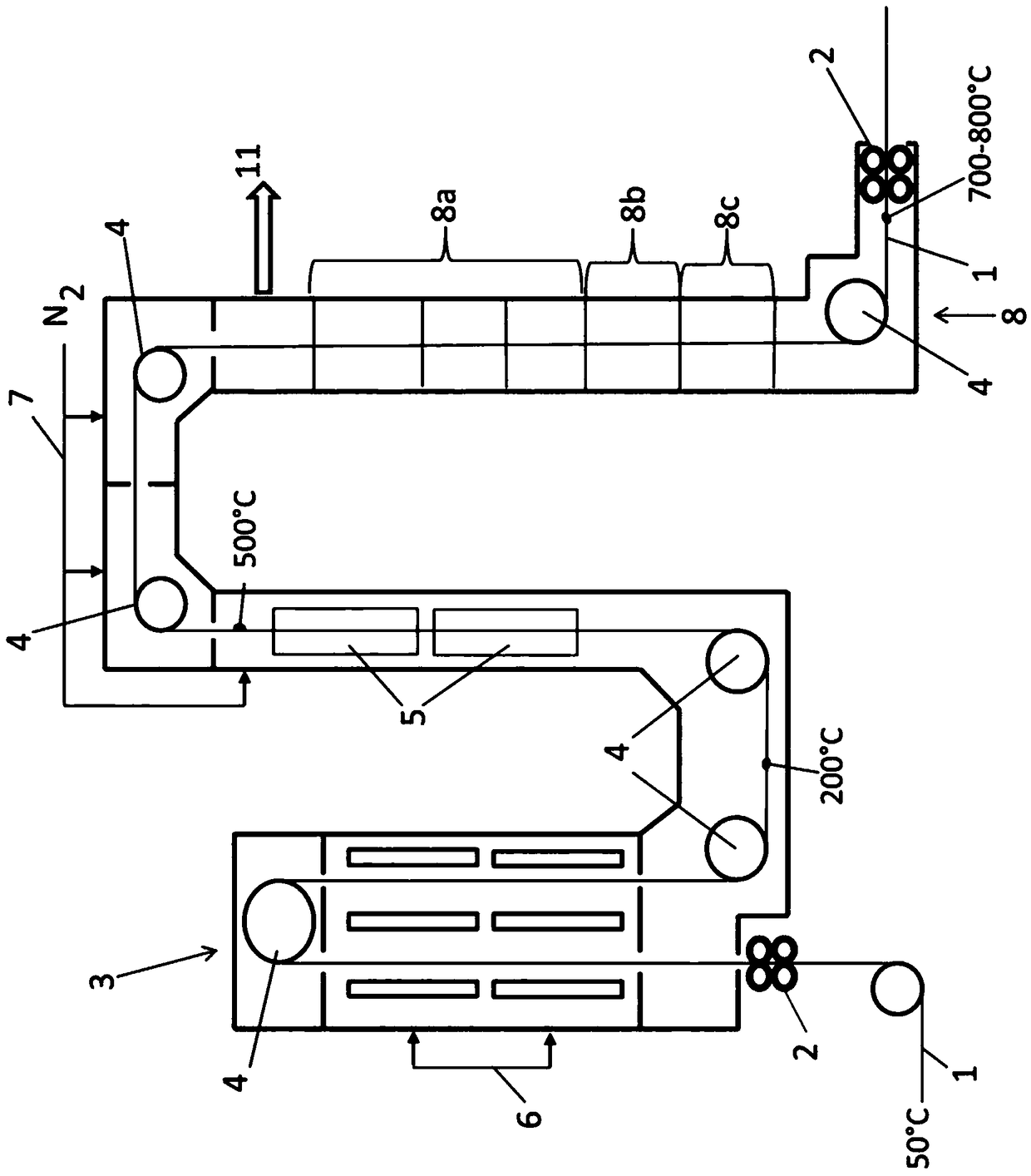

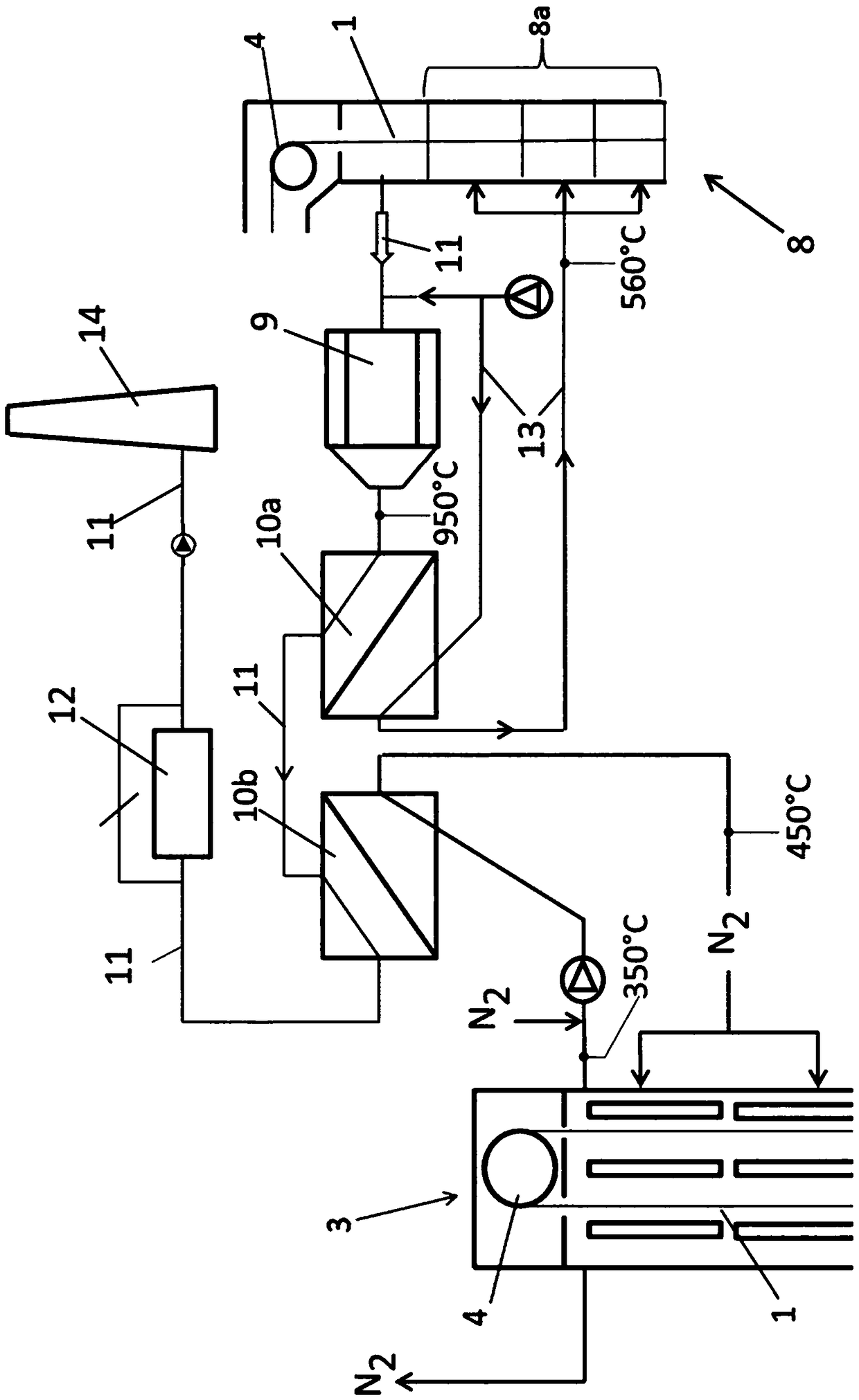

[0021] exist figure 1 At an entry temperature of approximately 50° C., the metal strip 1 passes through the pair of sealing rollers 2 continuously into the preheating zone 3 of the furnace installation and is heated there by means of hot nitrogen 6 to approximately 200° C. Hot nitrogen gas 6 is blown directly onto the metal strip 1 through nozzles. Turning rollers 4 guide the metal strip 1 through the furnace arrangement. Adjoining the preheating zone 3 , the metal strip 1 is further heated to approximately 500° C. in a protective gas atmosphere by means of an induction heater 5 . Nitrogen is also fed into this zone via line 7 . The metal strip then enters a direct-fired furnace 8, where the metal strip 1 is further heated in the starting zone 8a, and then the metal strip is stripped of the oxide layer in a reducing atmosphere at about 720° C. in the reducing zone 8b. Next, the metal strip 1 from which the oxide layer has been removed is subjected to an oxidizing atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com