Engine device

An engine and auxiliary machine technology, applied in the direction of engine components, machines/engines, lubricant conduit devices, etc., can solve the problem of low ratio of rigidity increase, and achieve the effect of increasing surface area, preventing deformation, and preventing poor rotation of camshafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

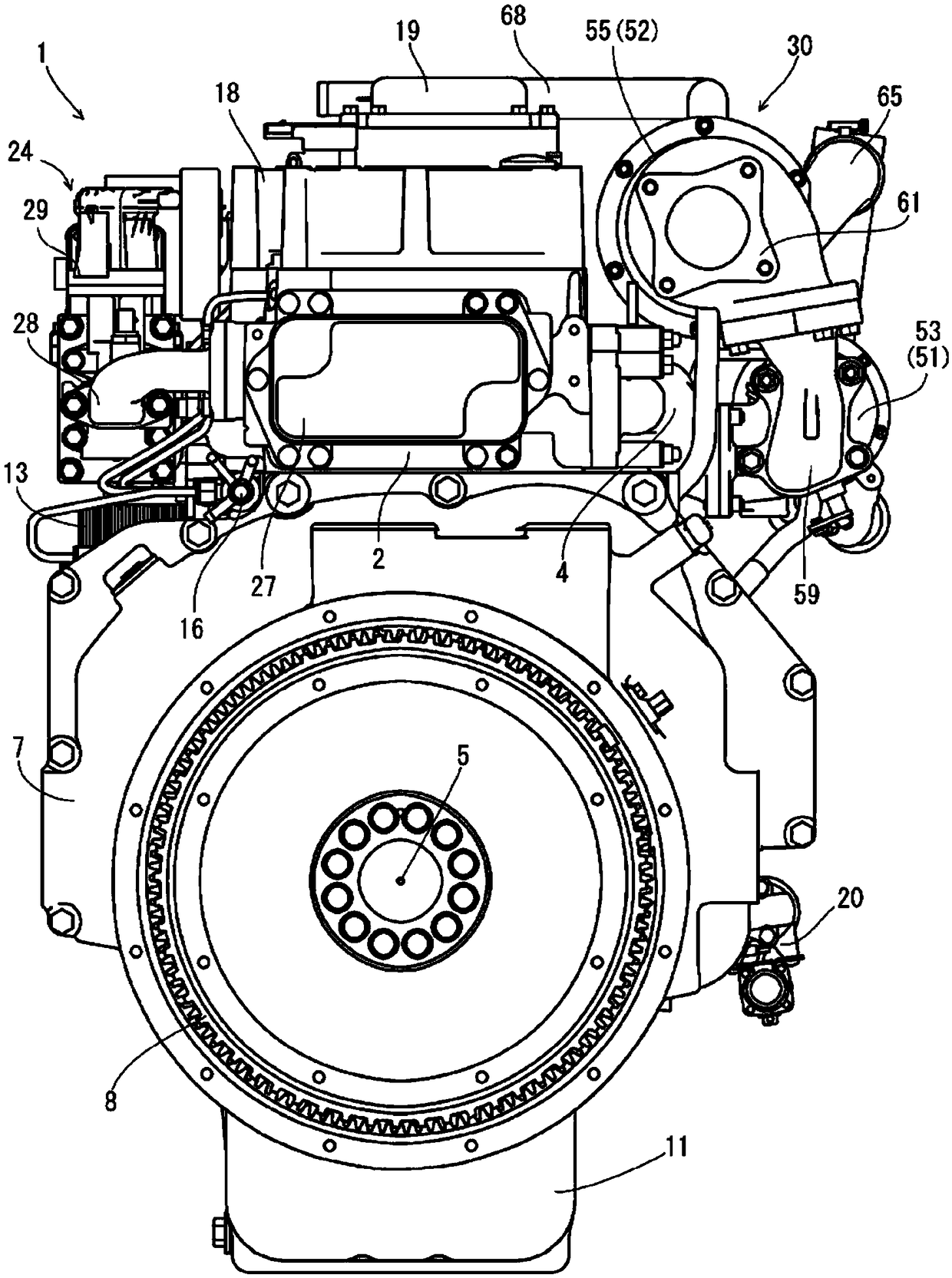

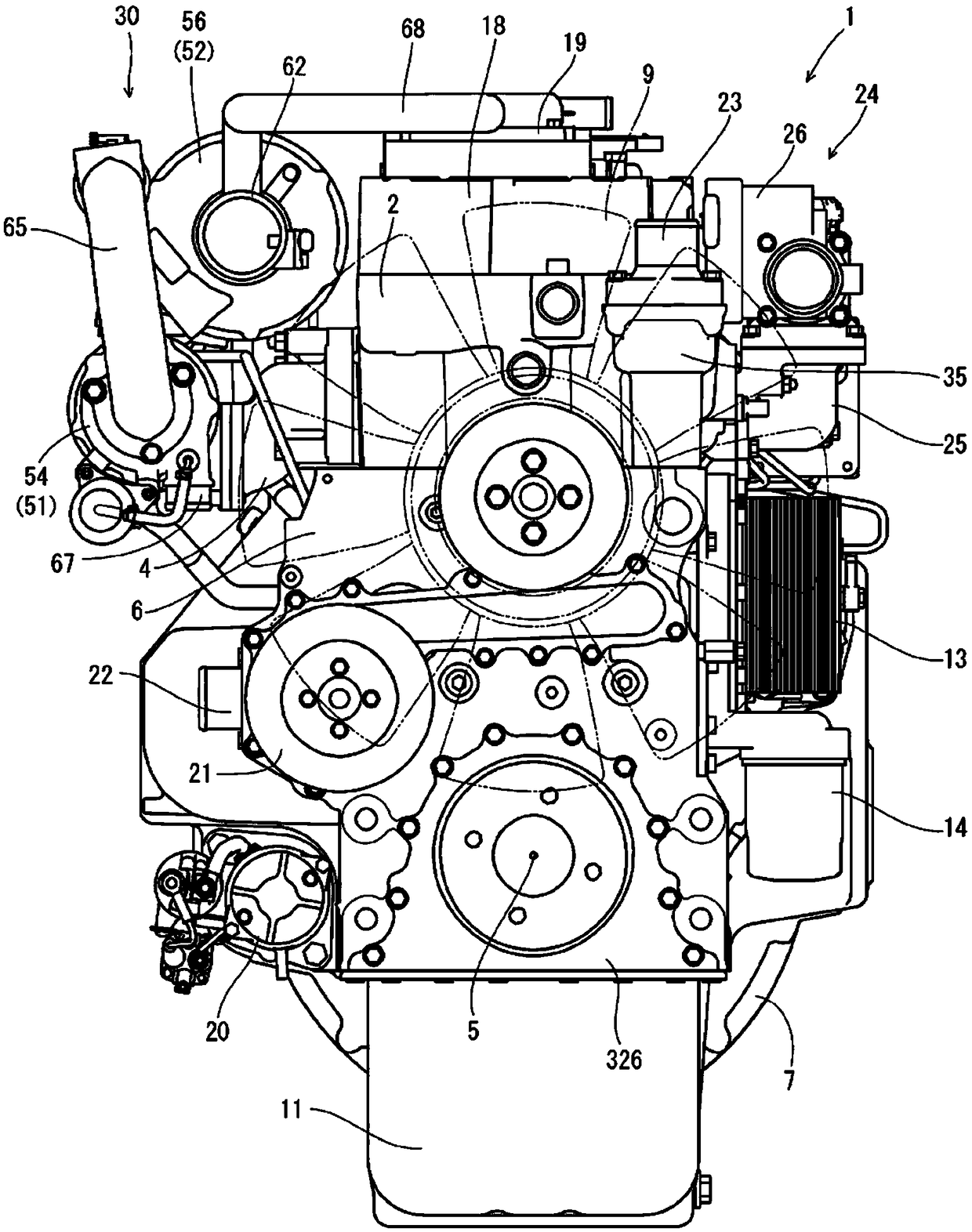

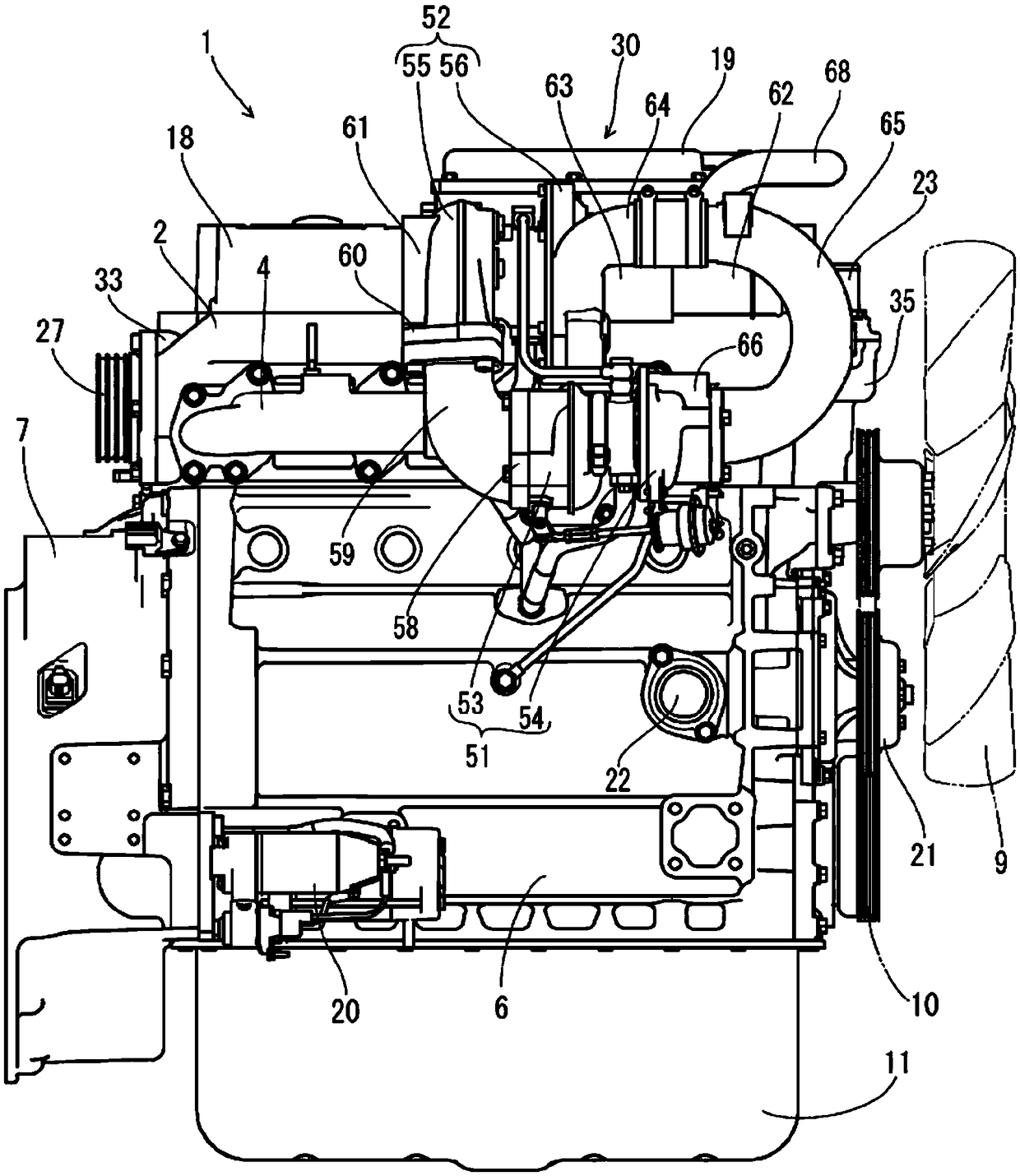

[0044] Hereinafter, specific embodiments of the present invention will be described based on the drawings. First, refer to Figure 1 to Figure 8 The overall structure of the diesel engine (engine unit) 1 will be described. In addition, in the following description, the two sides parallel to the crankshaft 5 (sides sandwiching the crankshaft 5) are called left and right, the side where the flywheel cover 7 is installed is called the front side, and the side where the cooling fan 9 is installed is called the front side. For the rear side, they are used as references for the four directions and the up and down positional relationship of the diesel engine 1 for the sake of explanation.

[0045] like Figure 1 to Figure 8 As shown, an intake manifold 3 is arranged on one side of the diesel engine 1 parallel to the crankshaft 5 , and an exhaust manifold 4 is arranged on the other side. In the embodiment, the intake manifold 3 is formed integrally with the cylinder head 2 on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com