Joint for concentration solar plants

A joint and elastic device technology, applied in the field of joints, can solve the problems of increased volume and damaged pipe structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

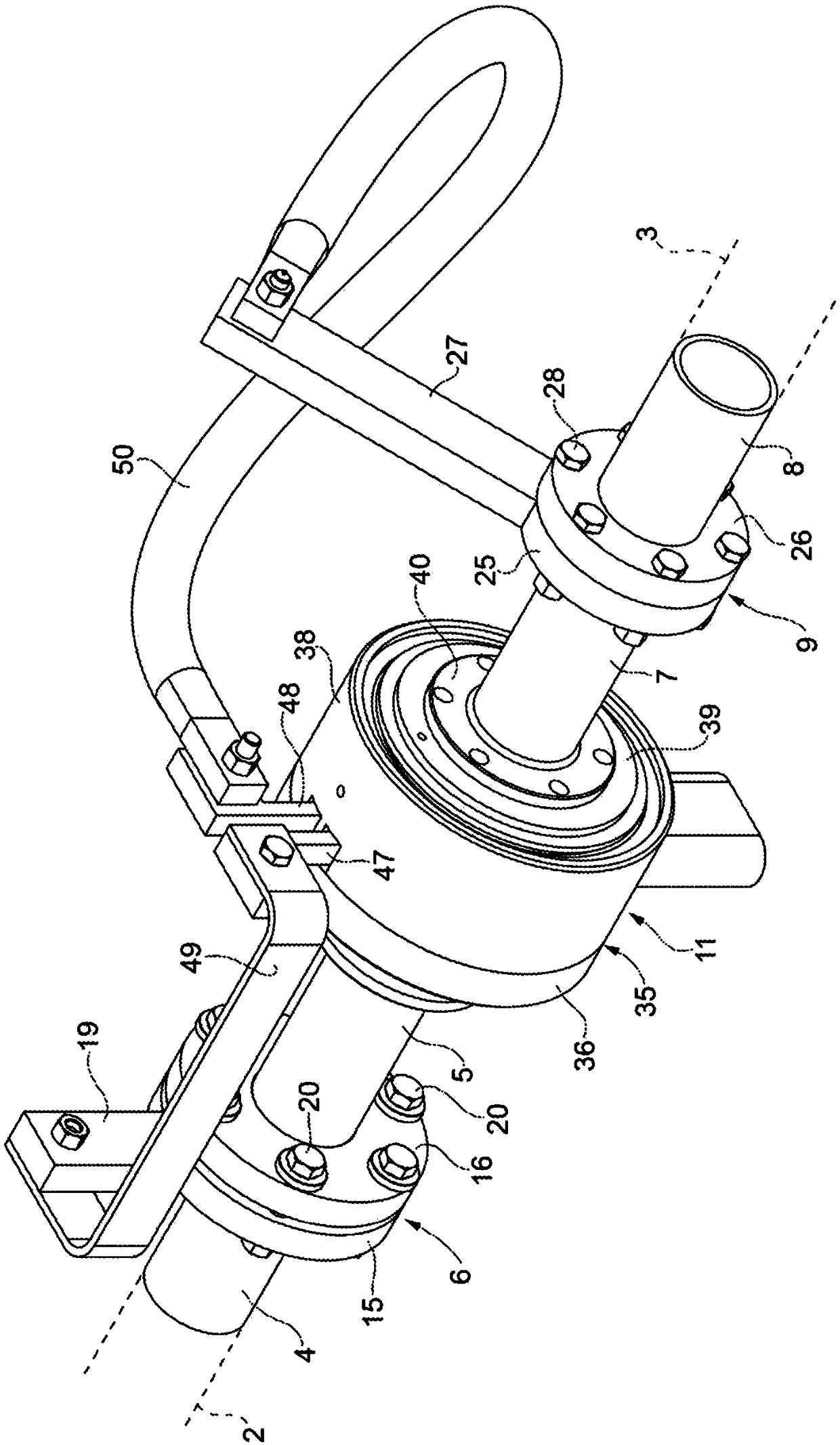

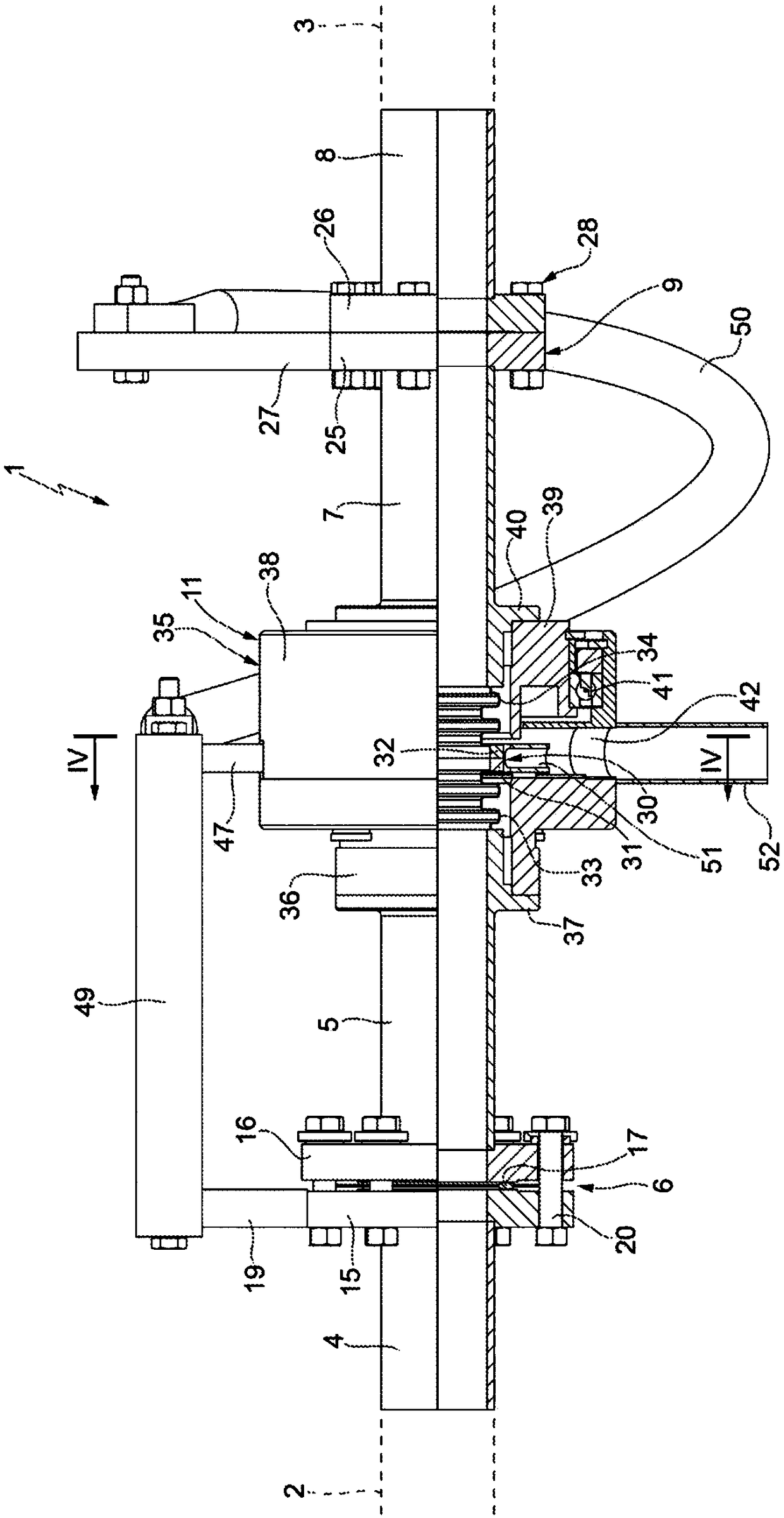

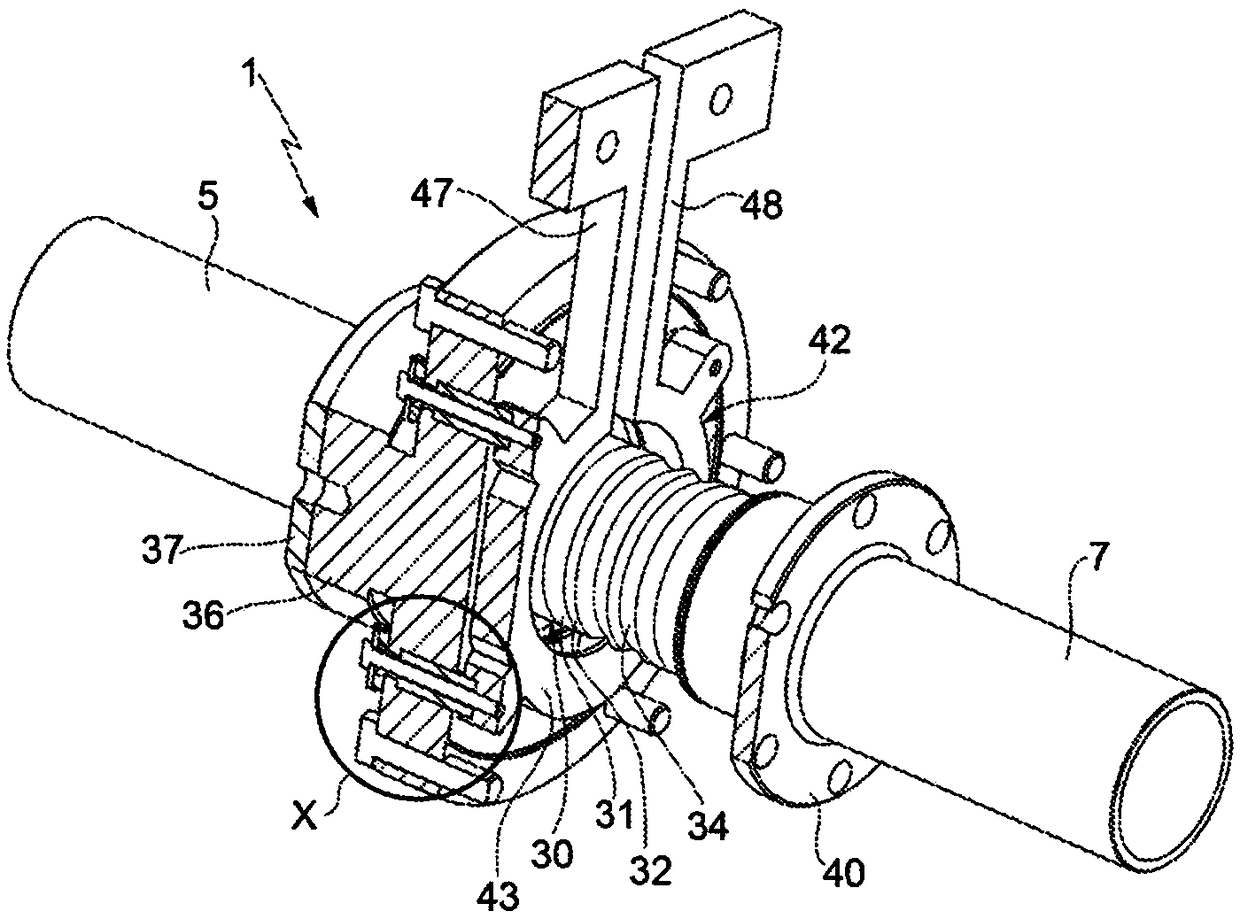

[0021] refer to figure 1 and figure 2 , reference numeral 1 as a whole designates a connecting unit for sealingly connecting two coaxial, mutually rotating tubes 2 , 3 (partially shown). In particular, pipe 2 may be formed by a fixed ground pipe; pipe 3 may be formed by a connecting pipe connected to a receiving pipe of a parabolic mirror of a CSP system (not shown) using a heat transfer fluid with a relatively high freezing temperature , such as NaNO 3 +KNO3. Tube 3 is preferably a flexible tube.

[0022] The connection unit basically consists of:

[0023] a first end tube 4 rigidly and sealingly connected to the tube 2;

[0024] first intermediate pipe 5;

[0025] an insulating joint 6 connecting the first end tube 4 to the first intermediate tube 5 and interposed axially between the first end tube 4 and the first intermediate tube 5;

[0026] the second tube 7; and

[0027] A swivel joint 11 sealingly connects the first intermediate tube 5 to the second tube 7 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com