Controlled heating method of a process fluid through concentrating solar thermal plant and heat carrier system and apparatus thereof

a technology of solar thermal plants and process fluids, applied in solar heat devices, solar heat storage, collector working fluids, etc., can solve problems such as variable heat conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

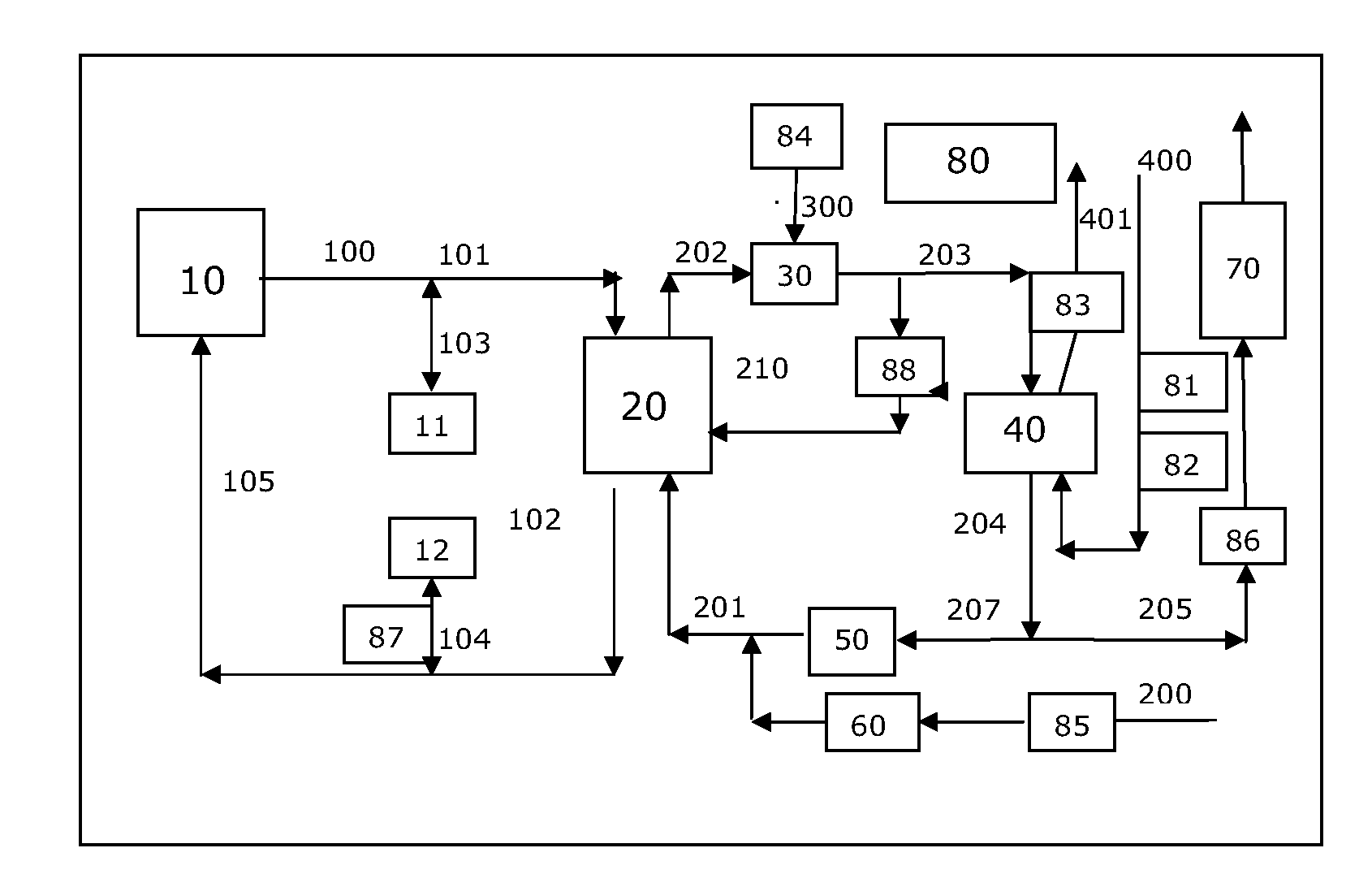

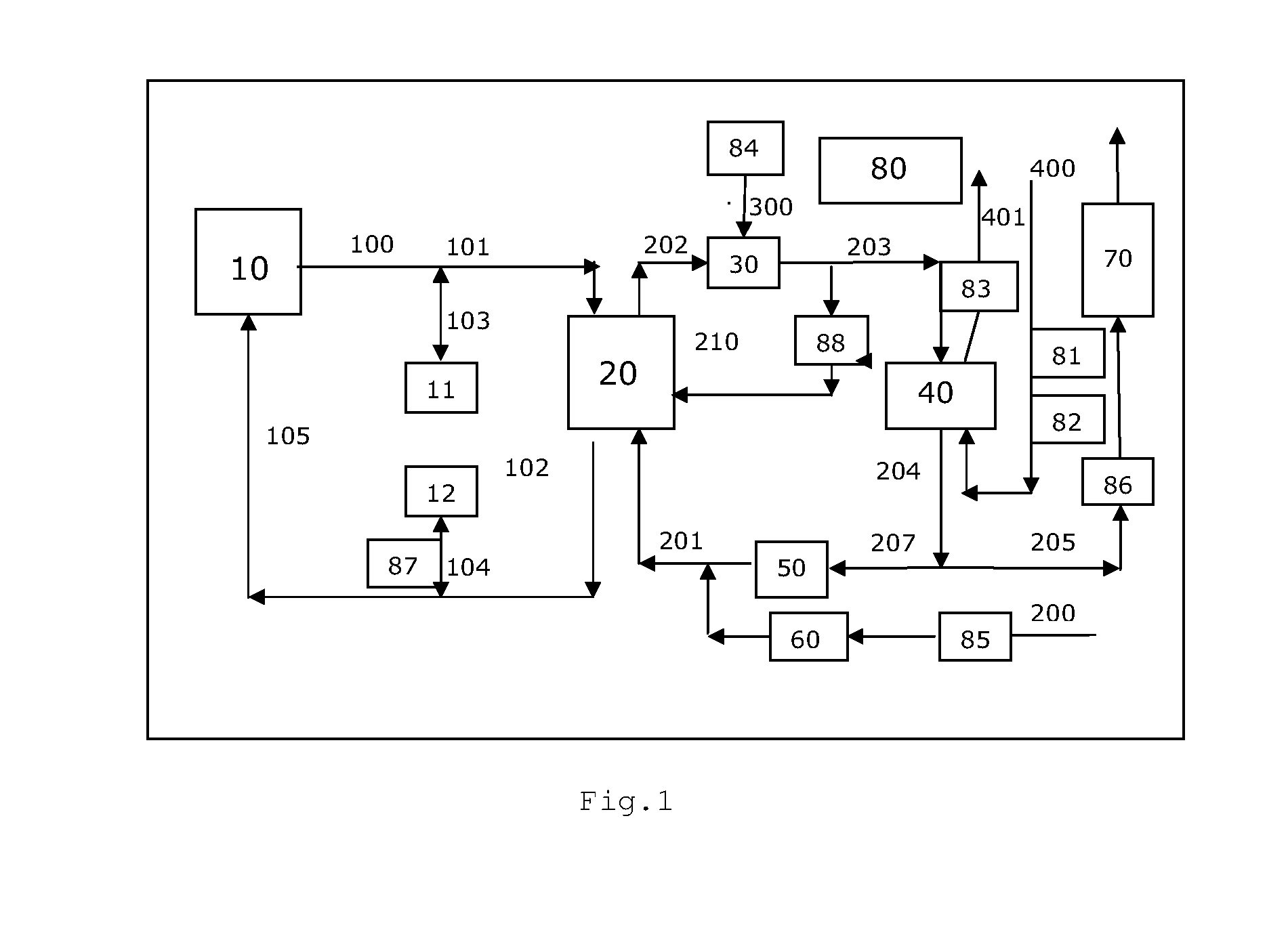

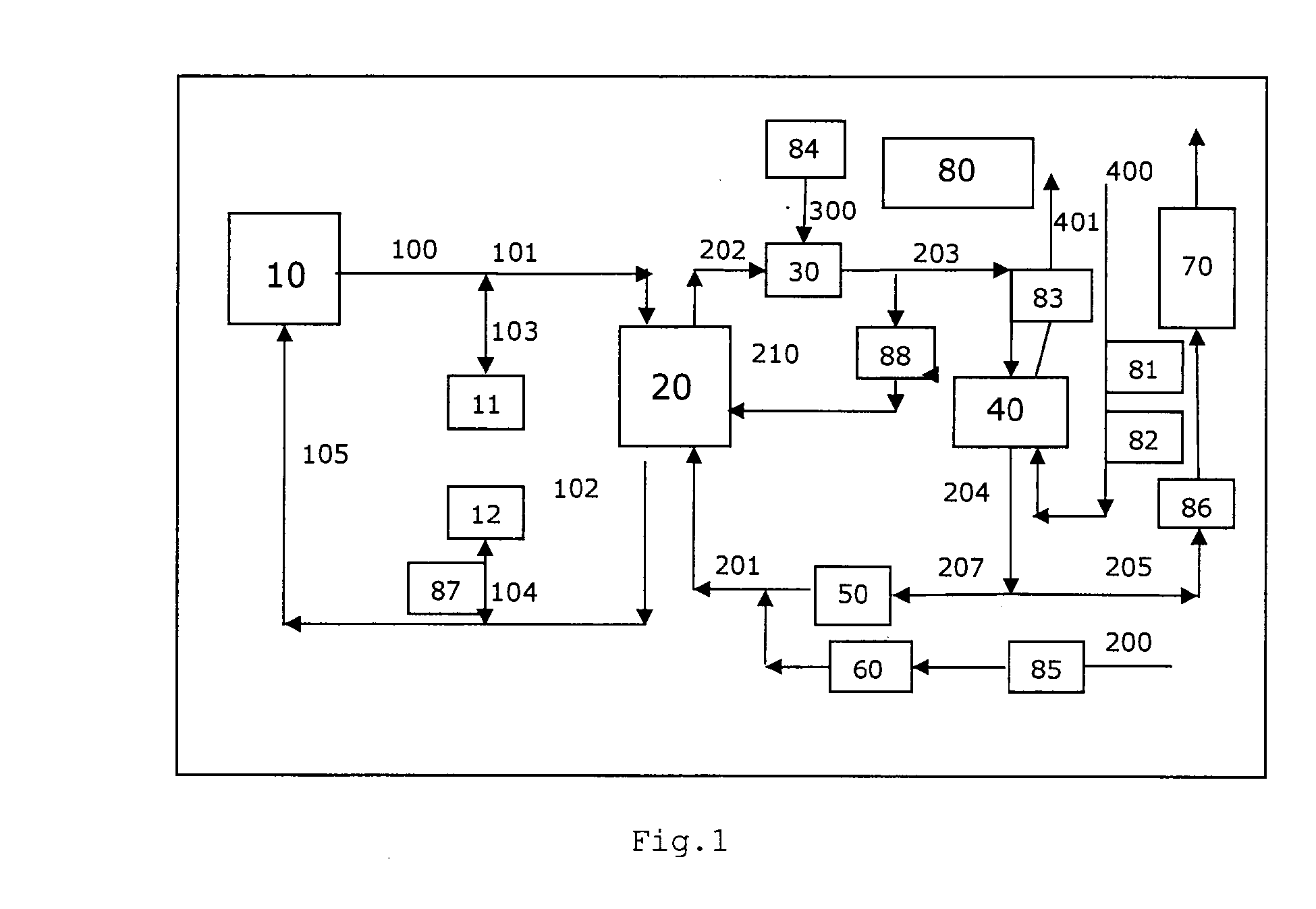

[0022]As illustrated schematically in FIG. 1 main components of the full architecture of present invention consist of a concentrating solar thermal plant 10, a heat exchanger 20 between molten salts and heat carrier and a heat exchanger 40 between heat carrier and process fluid.

[0023]The concentrating solar field 10 and storage system 11 and 12 based on molten salt circulation and storage is designed for absorbing and storing the heat necessary for the active and storage phase (about ⅔ of the continuous operation time of the required process heating).

[0024]The solar collection system 10 comprises one or more tube radiation absorbers and a plurality of through collectors, such a single axis parabolic reflectors.

[0025]Alternatively, any suitable means for concentrating solar radiation, such as Fresnel collectors, may be provided. The thermal fluid is heated within the receiver tubes upon exposure to direct and concentrated solar radiation.

[0026]The hot thermal fluid 100 coming from so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com