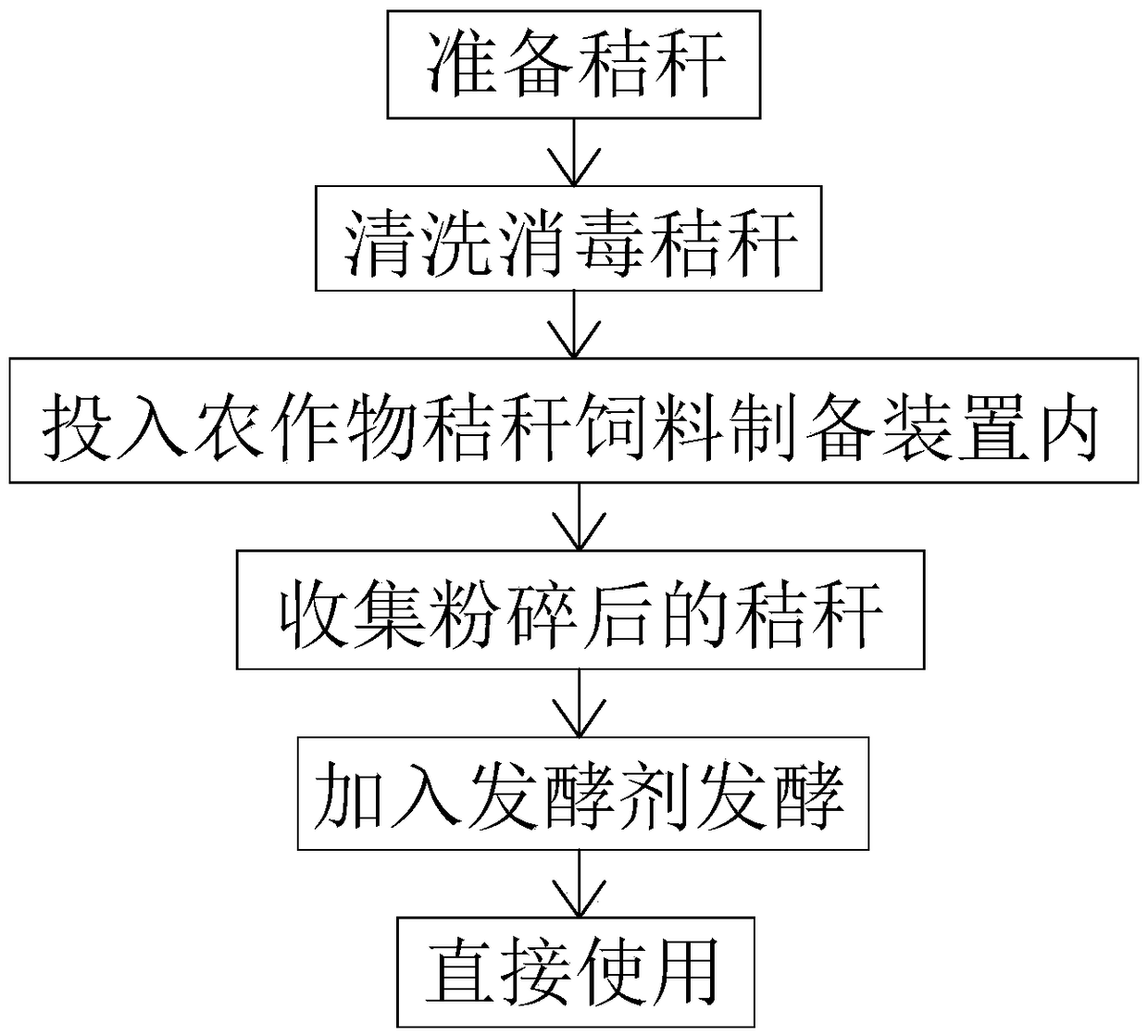

Crop straw feed preparation process

A technology for crop straw and production process, which is applied in animal feed, animal feed, agriculture, etc., can solve the problems of manual switching, troublesome operation, invisible whole process, etc., so as to reduce the phenomenon of straw entanglement, ensure the crushing efficiency, and reduce the crushing efficiency. thoroughly uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

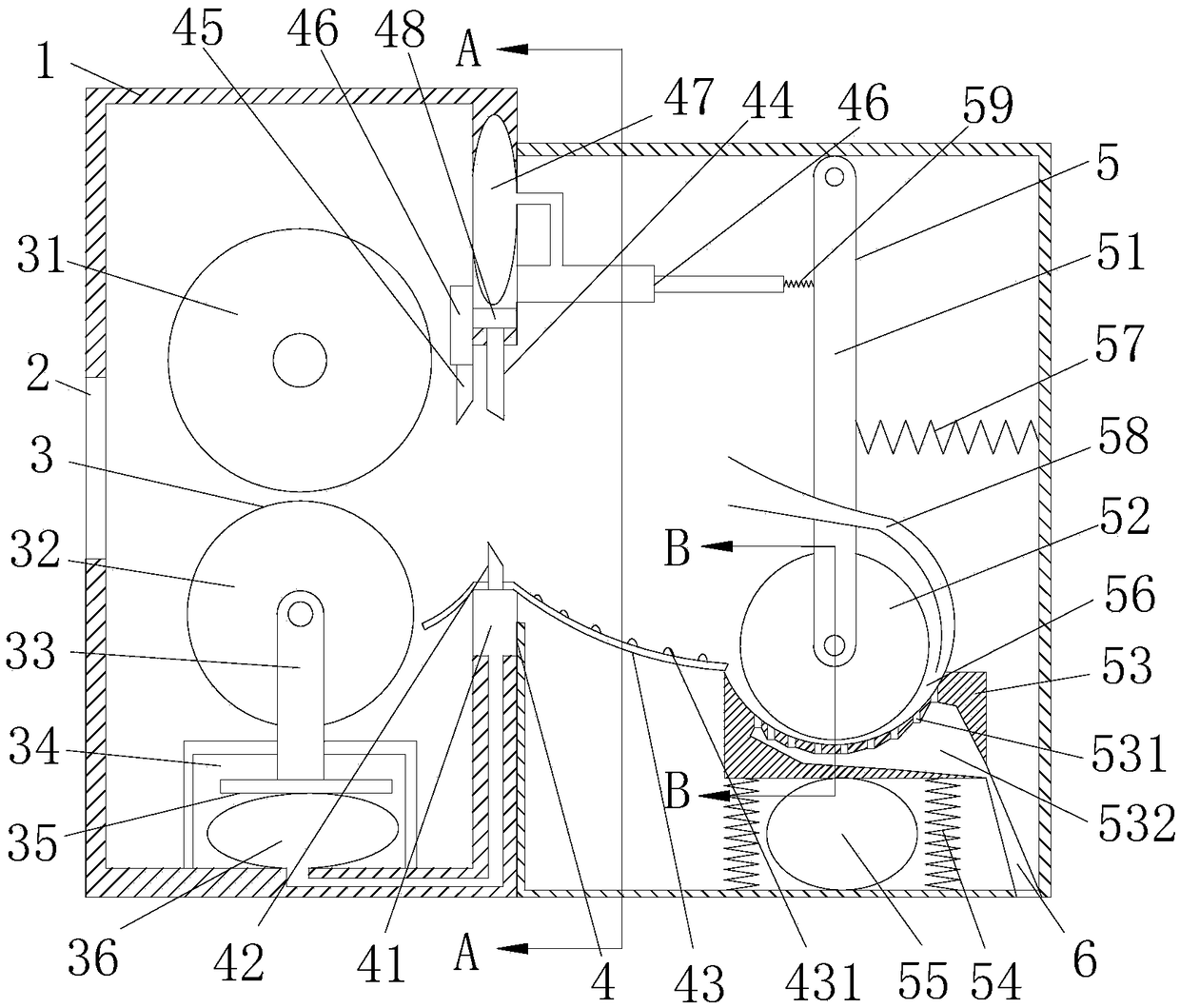

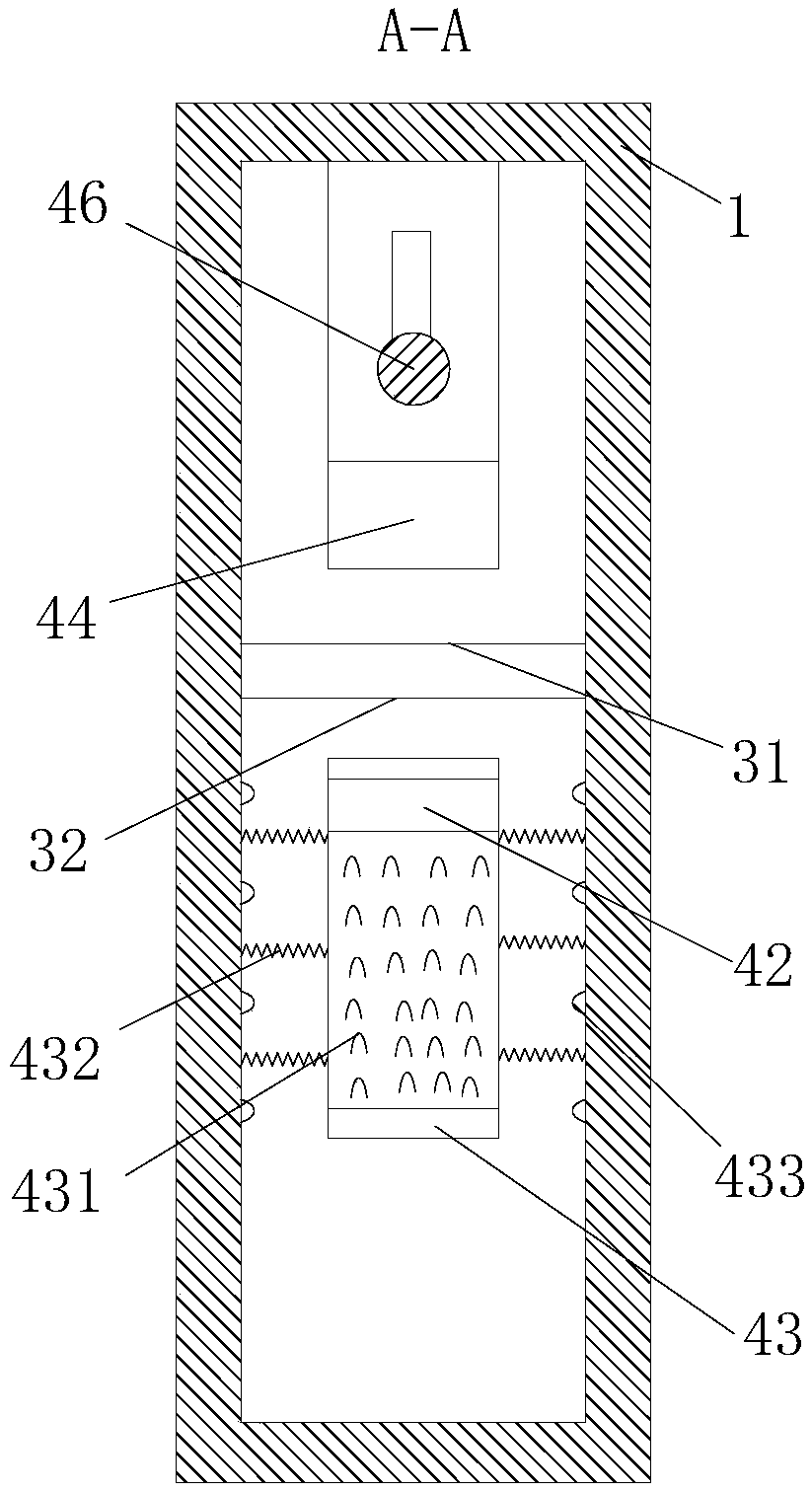

[0041] As an embodiment of the present invention, the crushing cabin 5 includes a swing rod 51, a crushing shaft 52, a vibrating block 53, a first spring 54 and a third air bag 55; the swing rod 51 is rotatably connected to the inner side of the frame body 1 surface; the left side of the swing rod 51 is provided with a second air cylinder 46 fixedly connected to the inner side of the frame body 1; the second air cylinder 46 communicates with the second air bag 47 through a trachea; The third spring 59 is fixedly connected between the end and the swing rod 51; the lower end of the swing rod 51 is rotatably connected with a crushing shaft 52; the lower end of the crushing shaft 52 is provided with a vibrating block 53; There is a crushing groove 56 on one side of the crushing groove. The crushing groove 56 is set on an arc surface, and the diameter is slightly larger than the diameter of the crushing shaft 52; when working, the crushing shaft 52 rotates and swings in the crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com