Sheet material sticking apparatus and sticking method

A technology for sticking device and sheet material, applied in the field of sheet material sticking device, can solve the problems of slow speed, low efficiency, high labor cost, etc., and achieve the effect of high efficiency, high degree of automation, and reduction of labor cost and time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

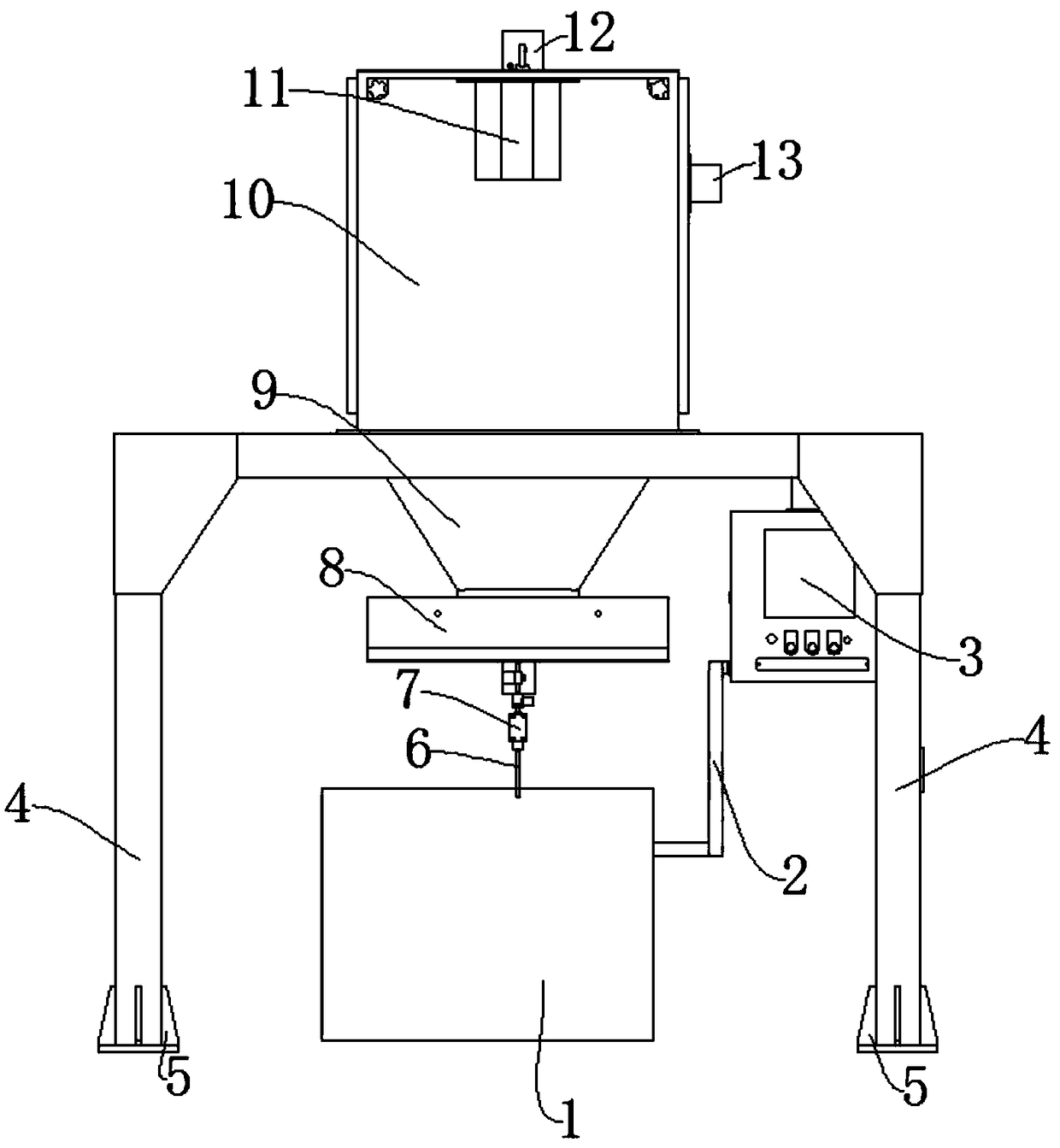

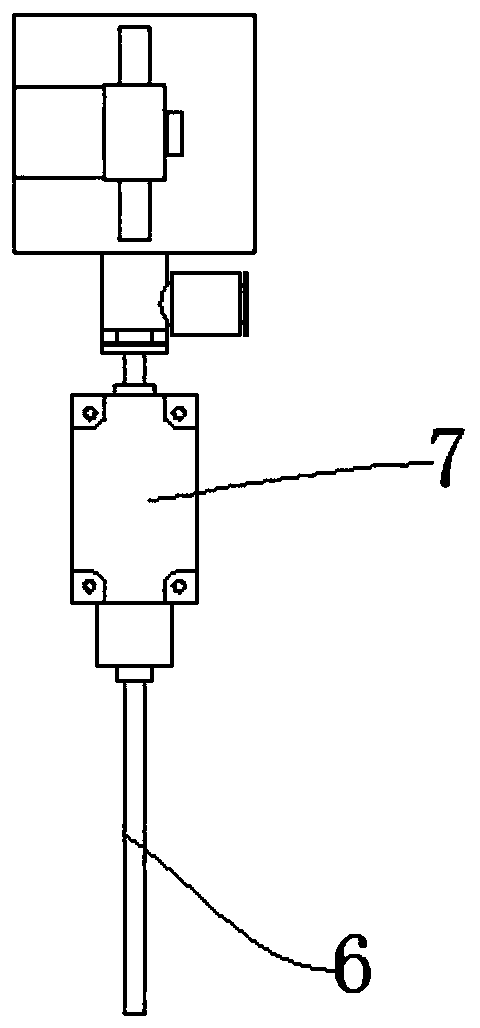

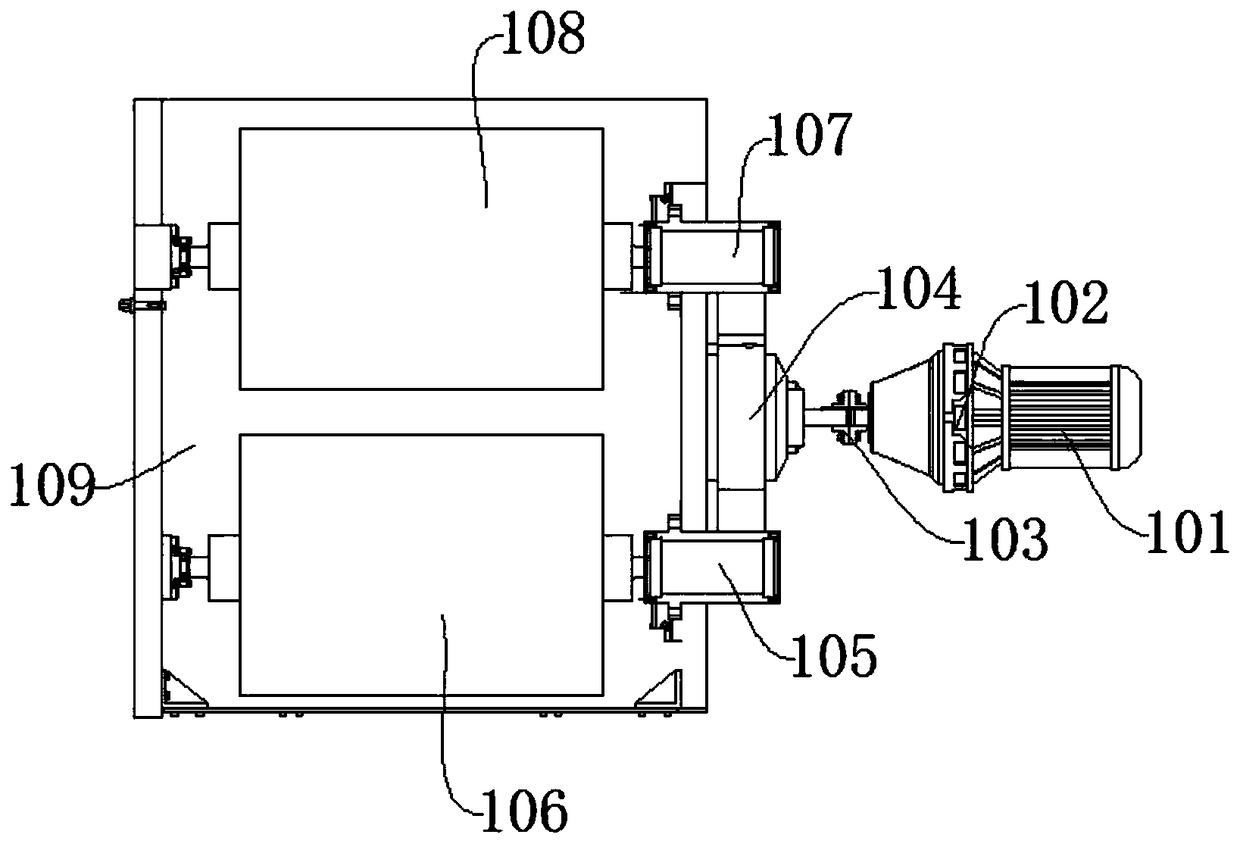

[0028] Such as Figure 1-Figure 4 As shown, a sheet pasting device includes a pasting box 1 and a glue box 10, the pasting box 1 is connected with a control cabinet 3 through a waterproof cable 2, and the control cabinet 3 is installed on the side of the support frame 4 , the bottom of the support frame 4 is provided with a buried fixing bolt 5, and an adhesive head 6 is arranged above the pasting box 1, and the adhesive head 6 is connected with a feed pump 8 through a restrictor 7, and the A feeding trough 9 is arranged between the feed pump 8 and the glue tank 10, and the inside of the glue tank 10 is provided with a heat preservation pipe 11, and the heat preservation pipe 11 is connected with a transformer 12, and the side of the heat preservation pipe 11 A rubber injection pipe 13 is arranged on the side, and the paste box 1 is composed of a motor 101, a gearbox 102, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com