Flexible LED filament bar

A technology of LED filament and LED chip, applied in the field of filament, can solve the problems of LED flip-chip damage, easy leakage current, and high price of flexible LED filament strips, and achieve the effect of avoiding metal wires, avoiding leakage current, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

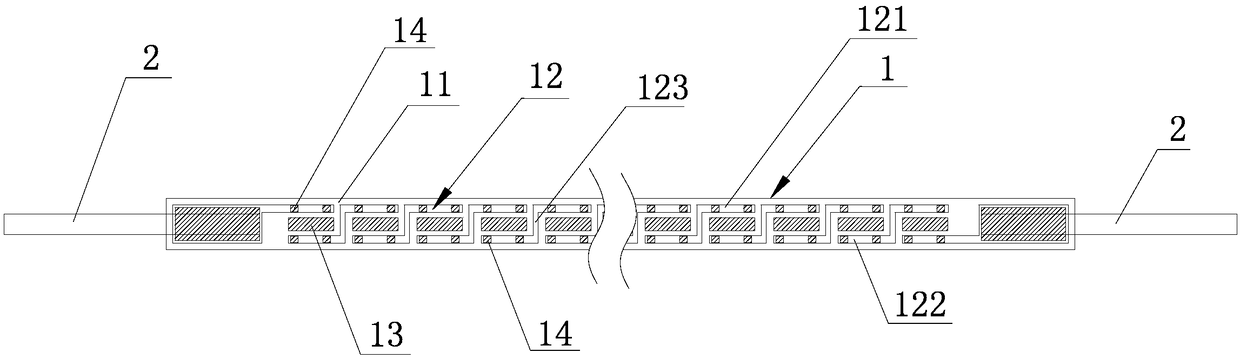

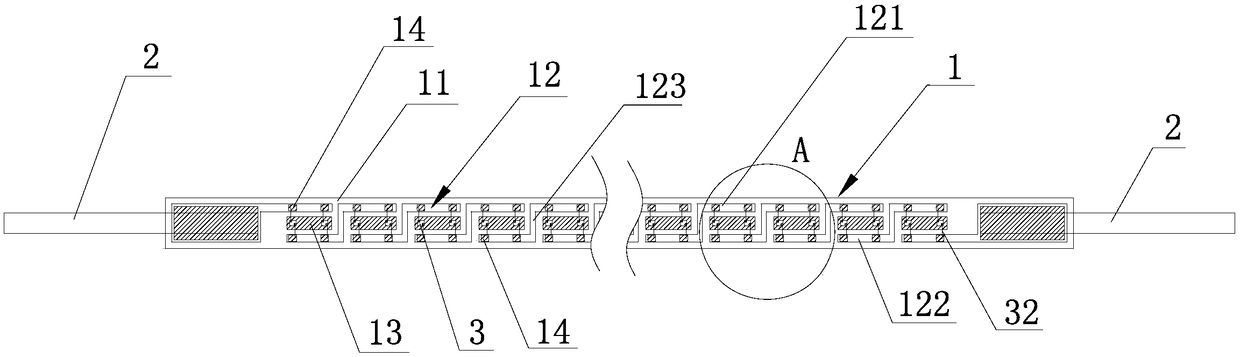

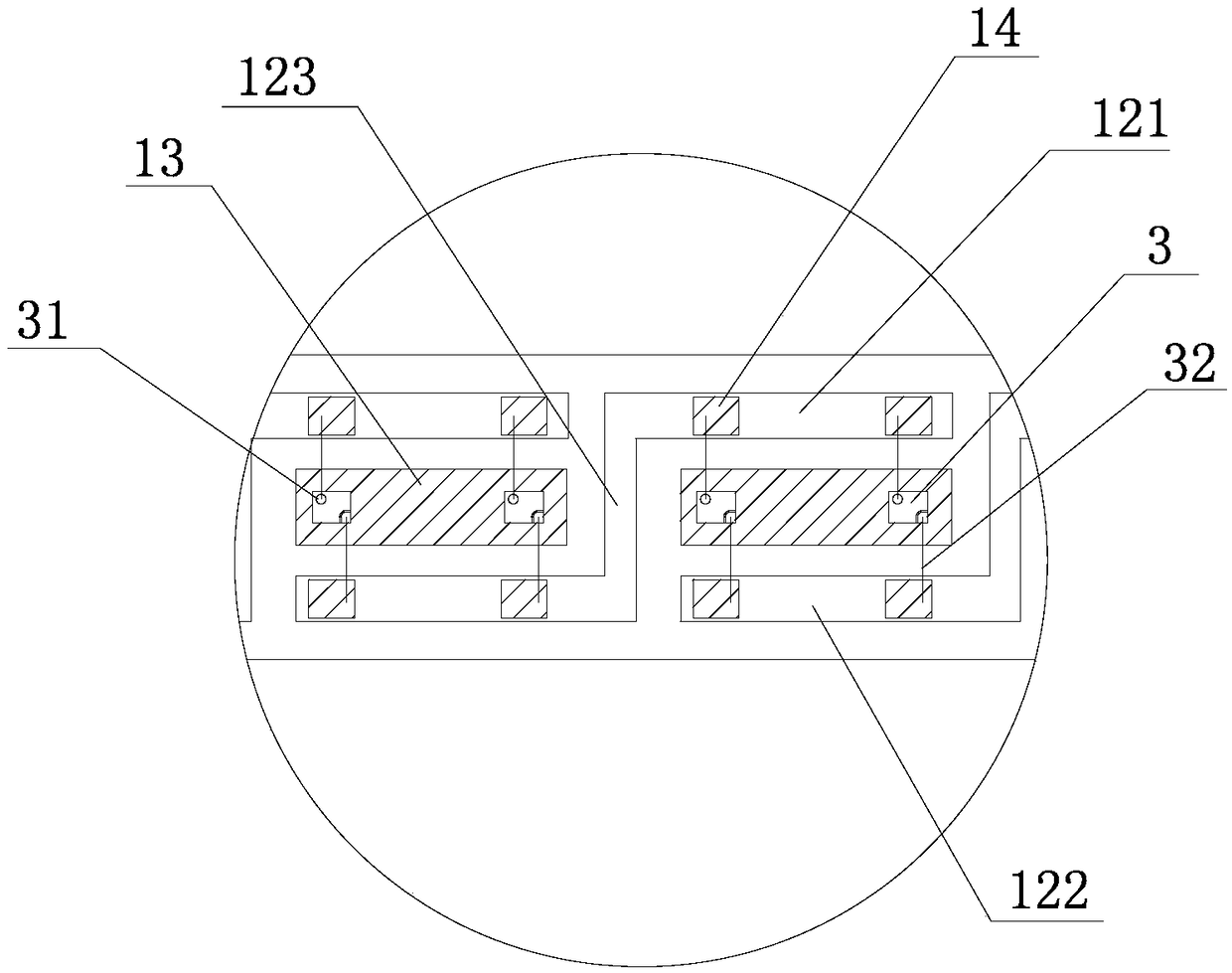

[0025] A kind of flexible LED filament strip that the present invention proposes, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a strip-shaped flexible metal circuit board 1, two metal electrodes 2 and a plurality of LED chips 3. The strip-shaped flexible metal circuit board 1 is composed of a strip-shaped flexible metal substrate 11 and a The printed circuit layer 12 on the front is composed of two metal electrodes 2 that are installed on the two ends of the strip-shaped flexible metal substrate 11 one by one. The two metal electrodes 2 are electrically connected to the printed circuit layer 12 respectively. The strip-shaped flexible metal substrate 11 A plurality of chip mounting areas 13 are reserved on the front side of the front surface, and each chip mounting area 13 is bonded with two formal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com