Powder box for printer

A technology for printers and toner cartridges, which is applied in the direction of electric recording technology applying charge patterns, equipment for applying electric recording technology with charge patterns, electric recording techniques, etc. Printing efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

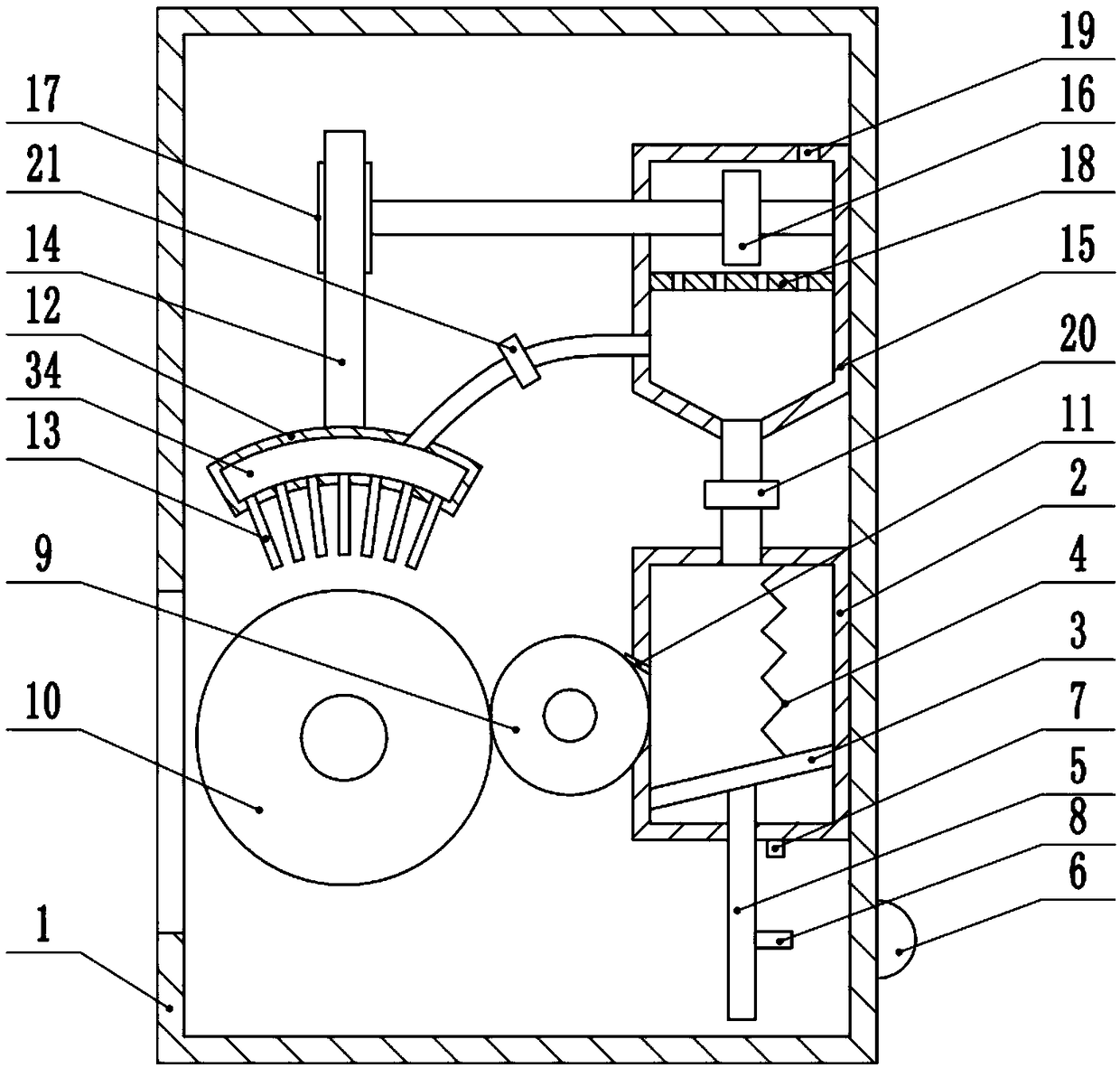

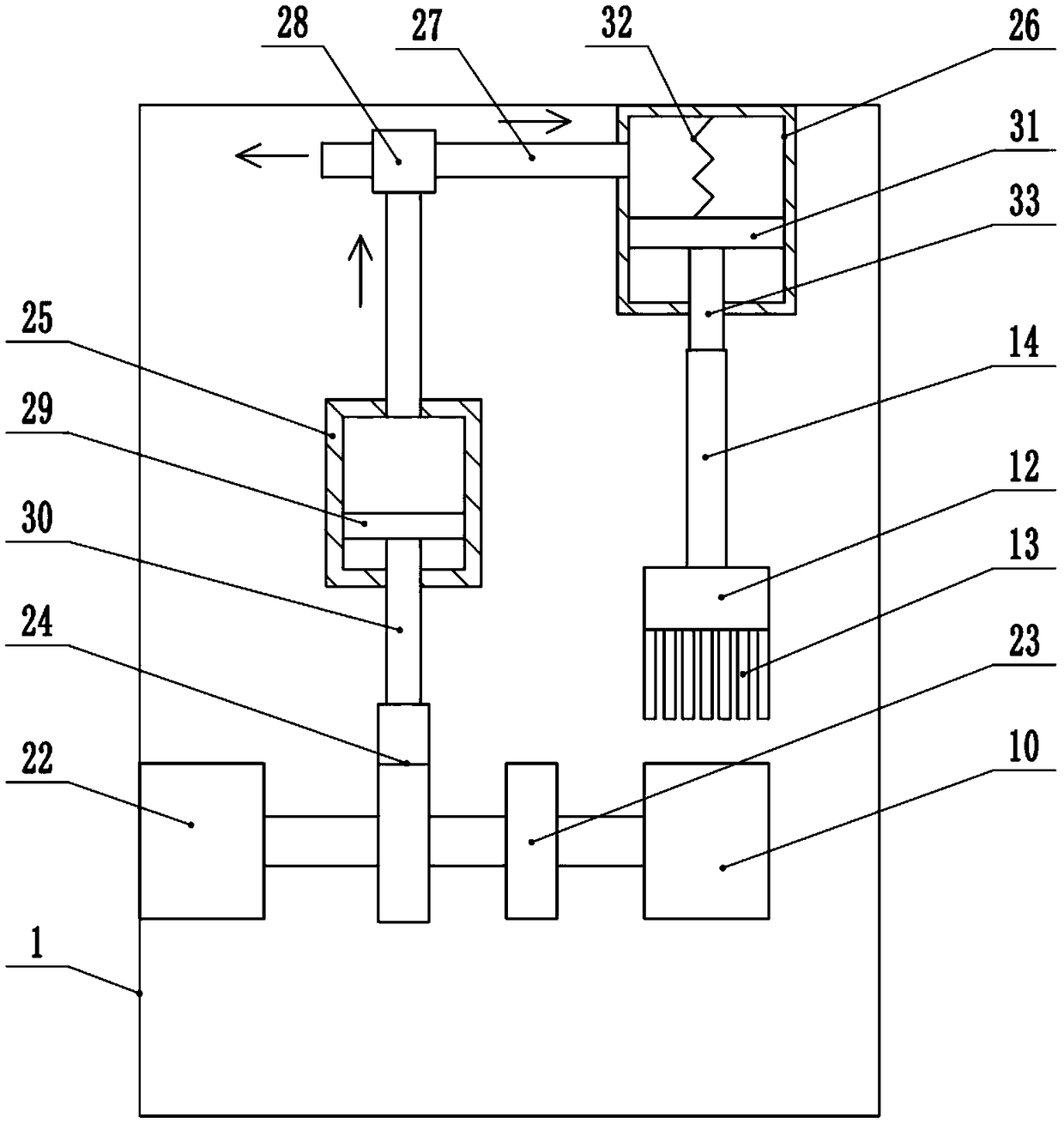

[0020] The reference signs in the drawings of the description include: box body 1, powder storage box 2, receiving plate 3, first spring 4, support rod 5, flashing light 6, switch 7, top block 8, powder roller 9, drum core 10, Scraper 11, cleaning plate 12, cleaning brush 13, transmission rod 14, recovery box 15, negative pressure blade 16, ratchet 17, filter plate 18, air hole 19, first one-way valve 20, second one-way valve 21, motor 22. First gear 23, cam 24, first cylinder 25, second cylinder 26, conduit 27, three-way valve 28, first piston 29, first piston rod 30, second piston 31, second spring 32 , the second piston rod 33, the cavity 34.

[0021] The embodiment is basically as attached figure 1 , figure 2 Shown:

[0022] A powder box for a printer, including a box body 1, a powder storage box 2 is fixedly connected to the box body 1, a powder outlet is opened on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com