Control strategy for achieving multivariable PID in PLS frame on basis of Gaussian process model

A Gaussian process model and control strategy technology, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve the problems of incomplete model establishment, poor control performance, and inability to eliminate multi-loop interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

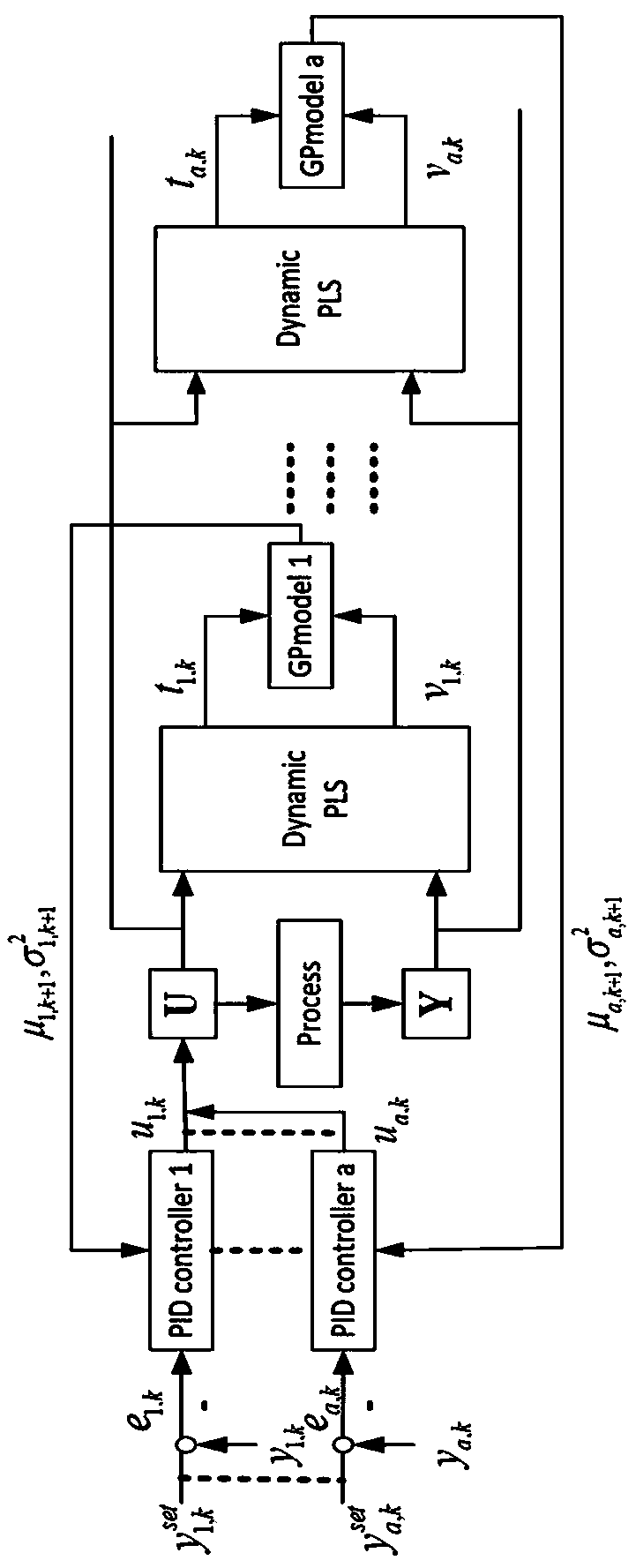

[0078] The multivariable PID control strategy is implemented in the PLS framework based on the Gaussian process model, including the following steps:

[0079] Step 1. Give the parameters of the PID controller:

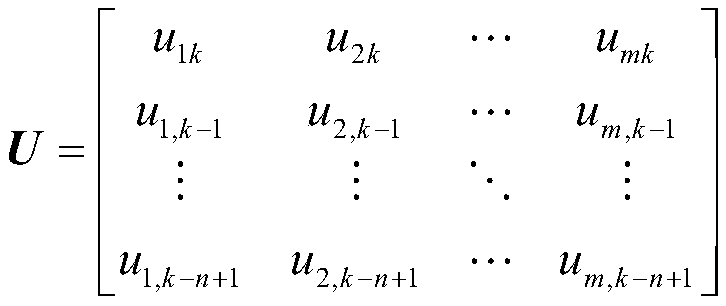

[0080] Consider a multivariate stochastic dynamical system with m inputs and l outputs: u k =[u 1k ,u 2k ,...,u mk ] T ,y k =[y 1k ,y 2k ,...,y lk ] T , where u k and y k They are the control input and the system output respectively; the setting values corresponding to each moment are given as follows:

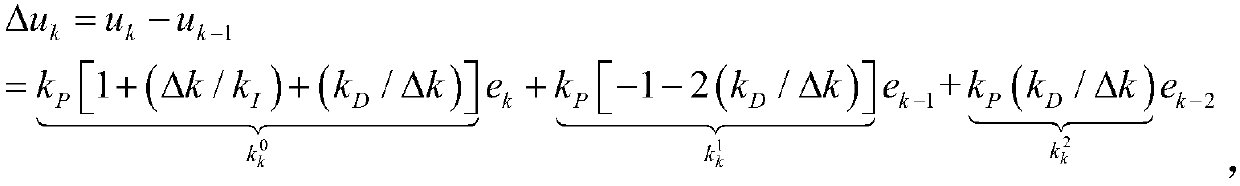

[0081] Next, the algorithm of the PID controller is given: where the error matrix is: parameter k P ,k I and k D are the proportional gain, integral time constant and differential time constant of the PID controller;

[0082] Therefore, the rate form of a discrete PID controller can be expressed as:

[0083]

[0084] where the parameter matrix and error matrix are respectively and

[0085] Step 2. In the PLS framework, use the Gaussian p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com