Carbon/graphene composite super-capacitor electrode materials and preparation method thereof

A graphene composite and supercapacitor technology, applied in the field of electrochemical energy storage, to achieve the effect of facilitating transmission, increasing energy density, and increasing area specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 2ml of 28% ammonia water dropwise to 20ml of 20mg / ml graphene oxide solution, stir for 30min, soak 8mm thick fir wood chips in the above solution, vacuumize for 24h, take it out, heat for a while, freeze Dry for 36h. Then carbonize at 700° C. for 60 min under the protection of argon to obtain a carbon / graphene composite material. Soak it in 2M potassium hydroxide solution to test its electrochemical performance.

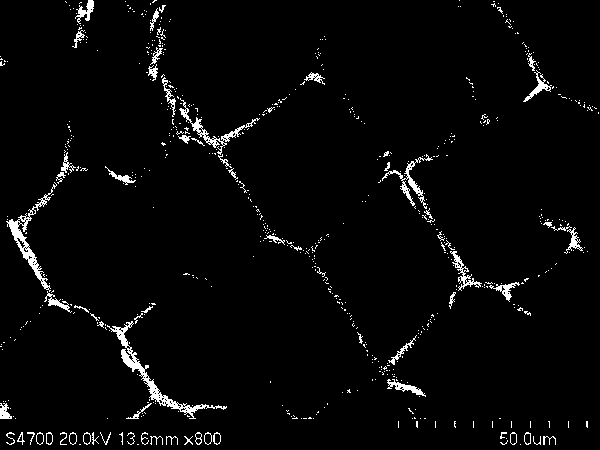

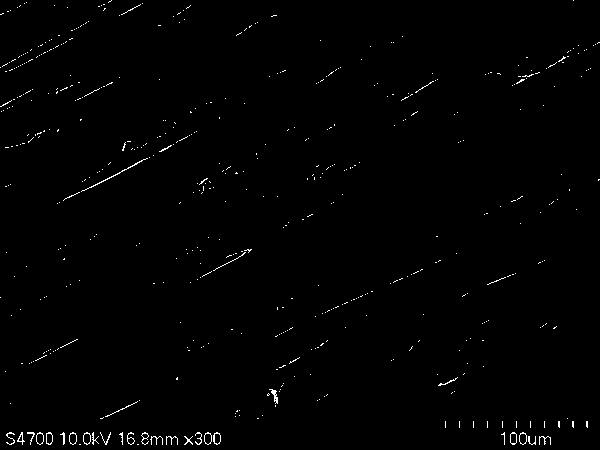

[0035] figure 1 It is the transmission electron microscope image of the prepared graphene oxide. figure 2 is the cross-section (perpendicular to the direction of tree growth) of the original fir wood chip, image 3 It is a longitudinal section (parallel to the direction of tree growth) of the original fir wood chip, and it can be seen that the original wood has many vertical porous structures. After pouring into the graphene oxide solution, pass Figure 4 (Cross-sectional view of wood impregnated with graphene oxide) and Figure 5 (Longitudinal cros...

Embodiment 2

[0037] Add 5mg of ascorbic acid into 20ml of 15mg / ml graphene oxide solution, stir for 30min, soak 16mm thick basswood chips in the above solution, vacuumize for 48h, take it out, heat for a period of time, and freeze dry for 48h. Then carbonize at 800° C. for 120 min under the protection of argon in a tube furnace to obtain a carbon / graphene composite electrode material. Soak it in 1M sulfuric acid solution to test its electrochemical performance.

Embodiment 3

[0039] Add 4 mg of citric acid to 10 ml of 10 mg / ml graphene oxide solution, stir for 30 min, soak 20 mm thick eucalyptus chips in the above solution, vacuumize for 48 h, take it out, heat for a period of time, and freeze dry for 48 h. Then carbonize at 900° C. for 180 min under the protection of argon in a tube furnace to obtain a carbon / graphene composite electrode material. Soak it in 1M sodium sulfate solution to test its electrochemical performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com