Method for supplementing lithium to negative pole piece

A technology for negative pole pieces and lithium supplementation, which is applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve the problems of complex process technology, stress deformation and wrinkles of base belt, lithium belt material requirements, etc., and achieve process control. The effect of reducing the difficulty, saving production costs and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] A method for supplementing lithium with a negative pole piece, comprising the following steps:

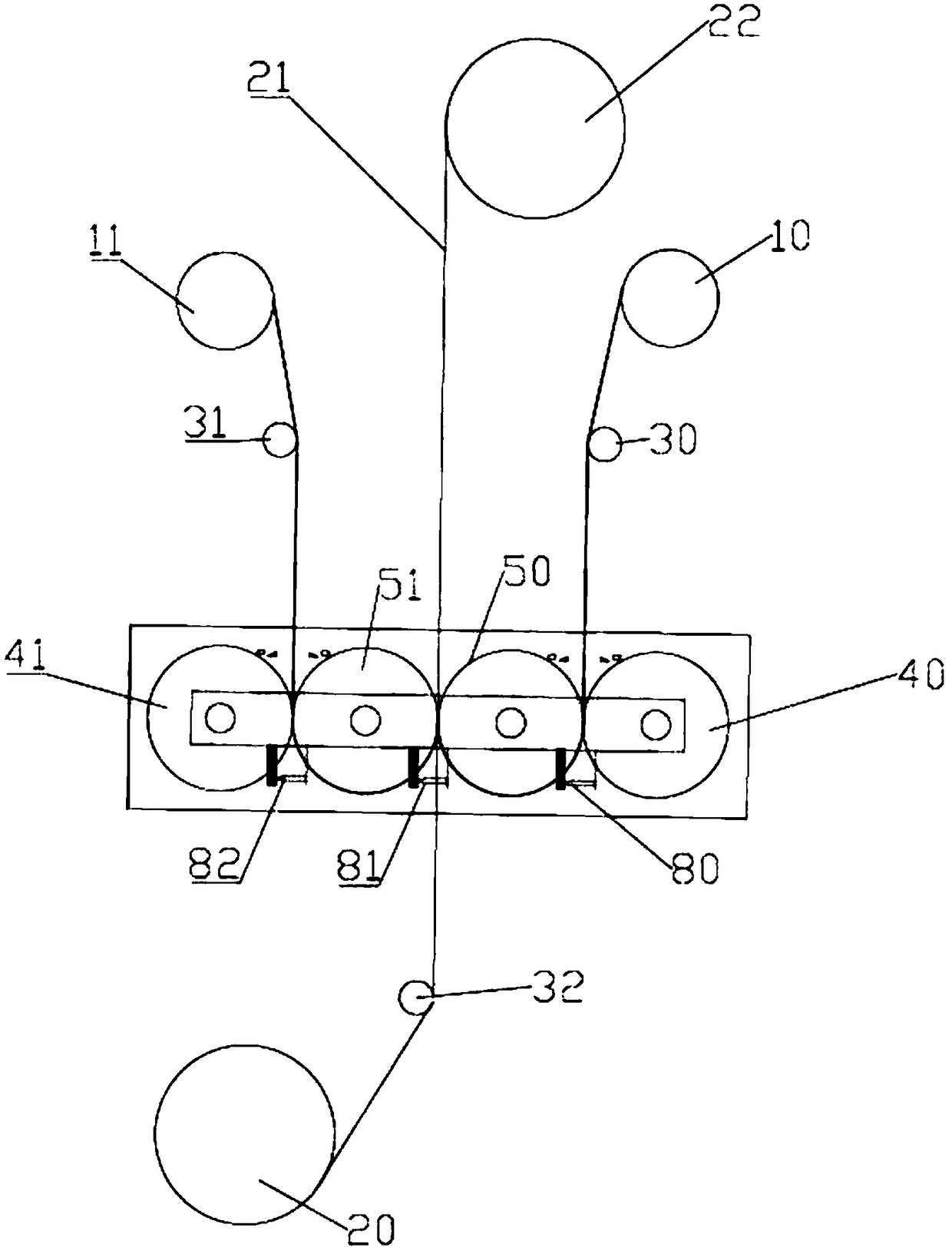

[0024] refer to figure 1 As shown, the adjacent first calendering roll 40, first composite roll 50, second composite roll 51 and second calendering roll 41 are arranged in sequence, and the first calendering roll 40, the first composite roll 50, the second composite roll 51 and the roll surface of the second calendering roll 41 are coated with silicone oil.

[0025] The viscosity of the silicone oil is selected at 50-5000cps, and the surface density of the silicone oil coating of the first calender roll 40 and the second calender roll 41 is 0.01-1g / m 2 ; The surface density of the silicone oil coating of the first composite roll 50 and the second composite roll 51 is 0.05-2g / m 2 ; The uniformity of coating can be guaranteed by a flexible scraper.

[0026] First unwind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com