Semiautomatic type pineapple harvesting integrated vehicle

A semi-automatic and automatic picking technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high labor intensity of workers and low efficiency of pineapple harvesting, so as to reduce work burden, protect plants and improve picking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

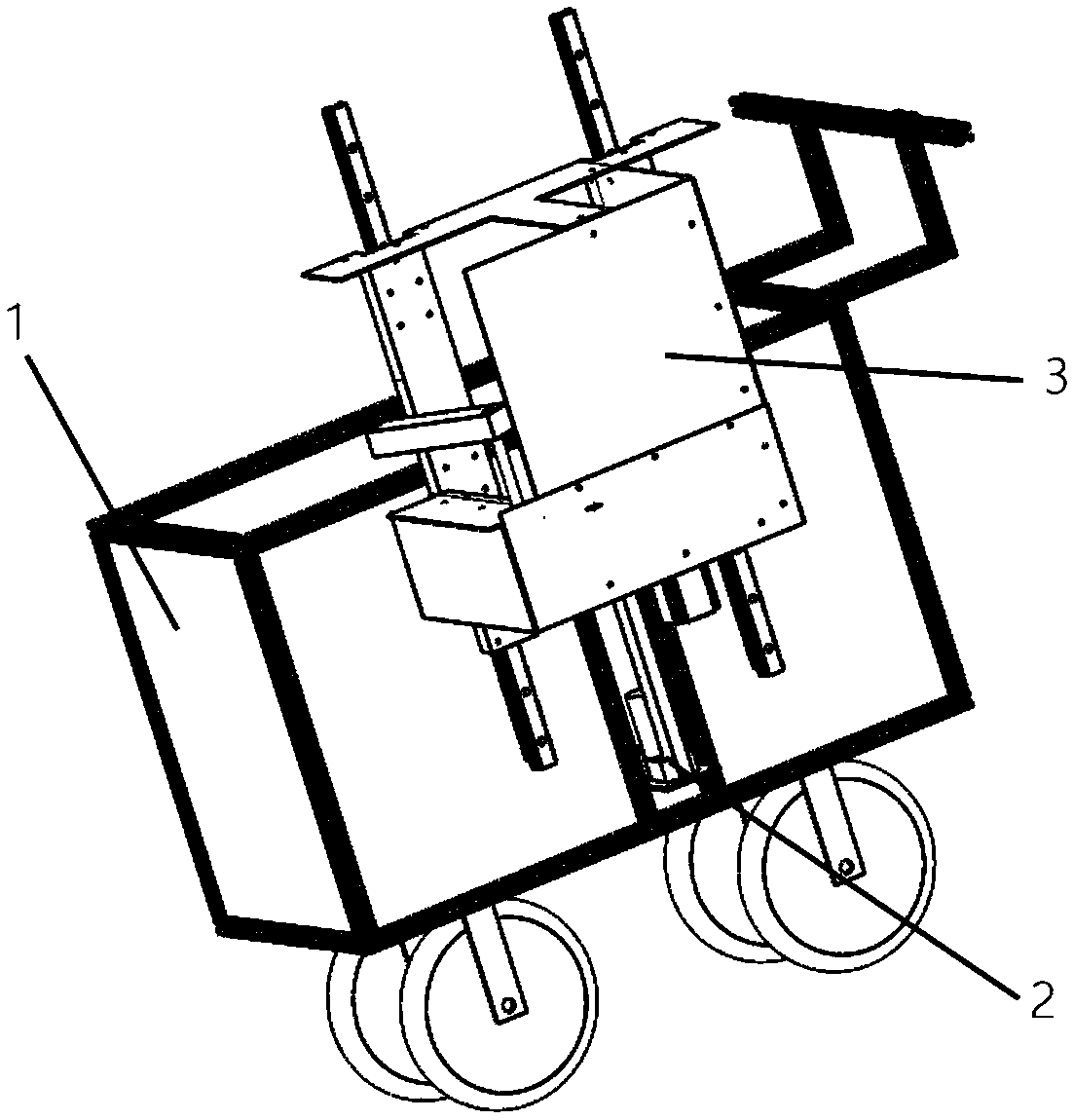

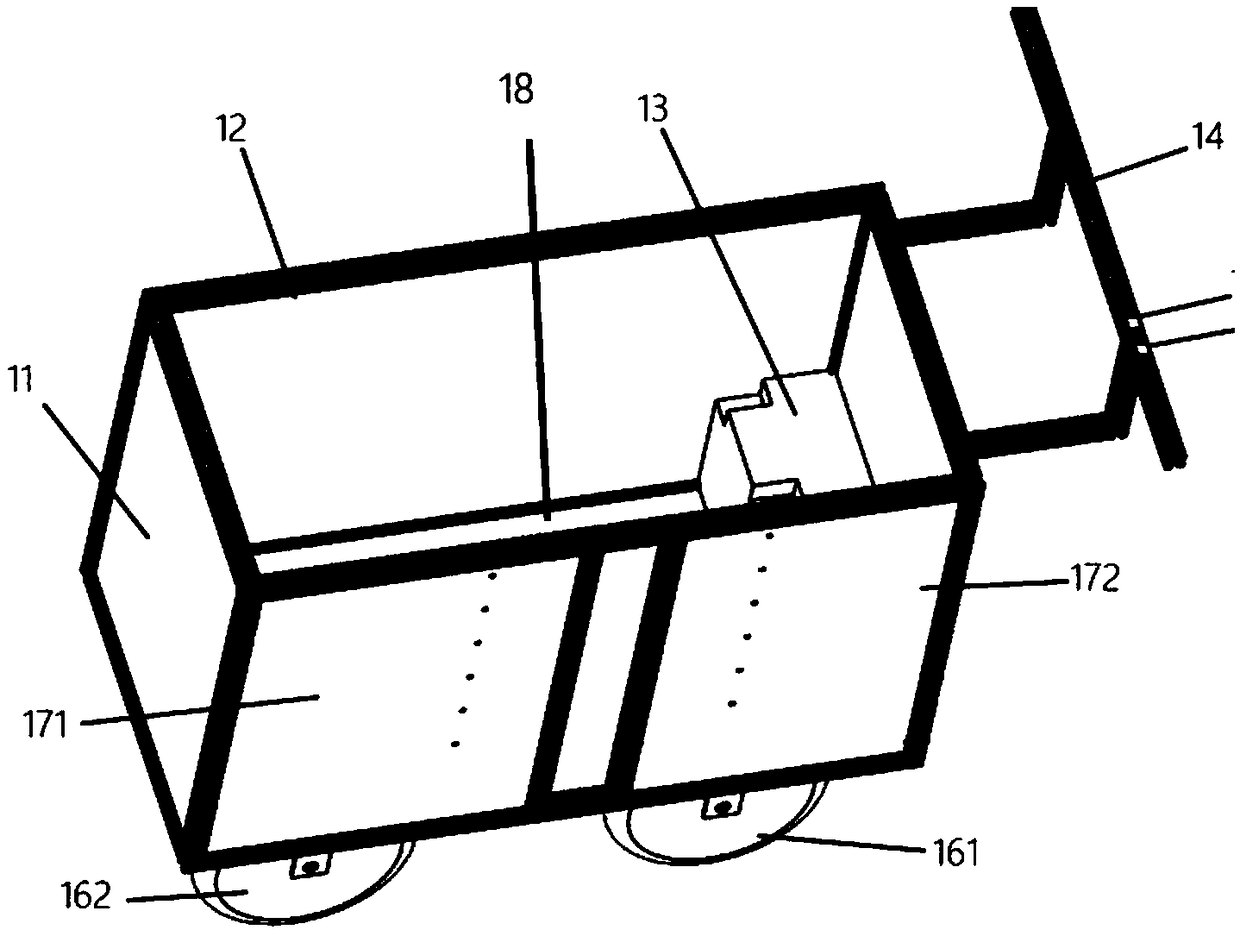

[0021] see Figure 1-Figure 5 As shown, a semi-automatic pineapple harvesting integrated vehicle includes a collecting device 1, a lifting device 2 and an automatic picking mechanism 3;

[0022] Described collecting device 1 is the box body that has handlebar 14, and the bottom of box body is equipped with wheel;

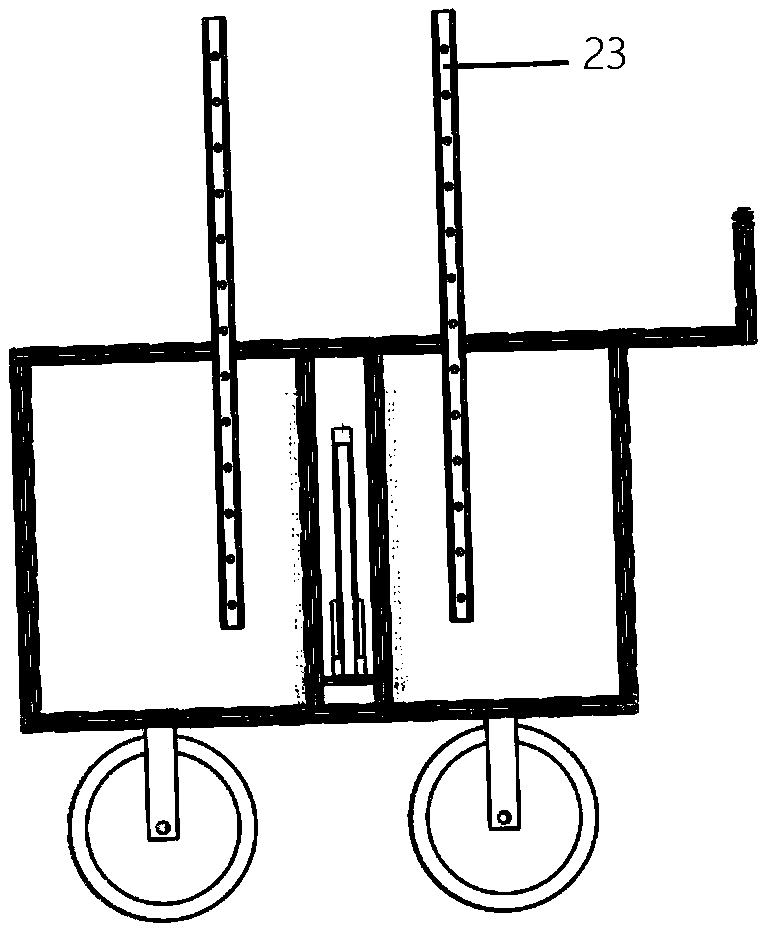

[0023] The lifting device 2 is an electric drive lifting device, which is fixed on the side plate of the box;

[0024] Described automatic picking mechanism 3 comprises picking motor 31, cutting blade 324, fixed stop guard frame, guide plate 325, base plate 326, picking hand 331, connecting rod 332 and transmission mechanism; The pineapple inlet and the pineapple outlet connected with the inner cavity of the box; the picking motor 31 is installed on the bottom of the base plate 326, and the fixed barrier guard is installed on the base plate 326, and the base plate 326 is fixed on the output end of the lifting device 2, and the fixed barrier guard The frame is limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com