Novel vertical flow type sedimentation tank

A vertical flow sedimentation tank and sedimentation tank technology, applied in the field of wastewater treatment sedimentation devices, can solve the problems of unsatisfactory sludge discharge effect, increased construction cost of sedimentation tank, complicated structure of sedimentation tank, etc. Good mud removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

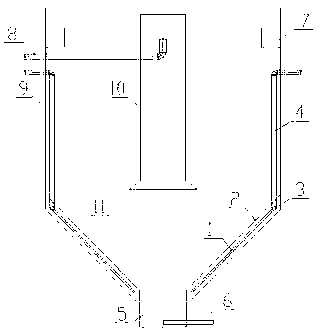

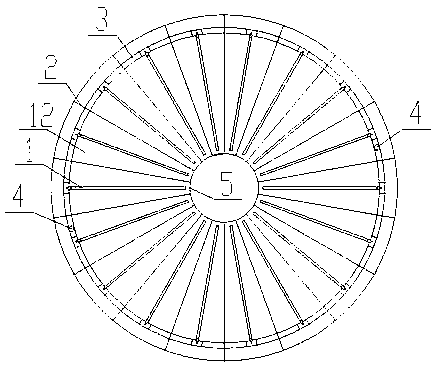

[0012] see figure 1 , figure 2 , the waste water enters the central pipe 10 of the sedimentation tank from the water inlet pipe 8, and after passing through the central pipe 10, the water enters the sedimentation area upwards. During the upward flow, the water flows upwards, while the mud settles downwards, and finally the clarified water is discharged through the outlet weir 7 , and the mud settles down to the surface of the conical sludge hopper 11 . A diversion groove 12 formed by a deflector 2 is arranged on the surface of the conical sludge hopper. When the surface 11 of the conical sludge bucket accumulates a large amount of sludge due to precipitation, the pressure water passes through the water distribution vertical pipe 4 and the water distribution ring pipe 3, and finally enters the porous water distribution disturbance pipe 1, relying on the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com