Non-contact laser processing spring piece chuck for irregular polyhedron

A laser processing and spring leaf technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing difficulty, long solidification time, and increasing clamping cycle, so as to improve clamping efficiency and clamping reliability. , Simple effect of clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

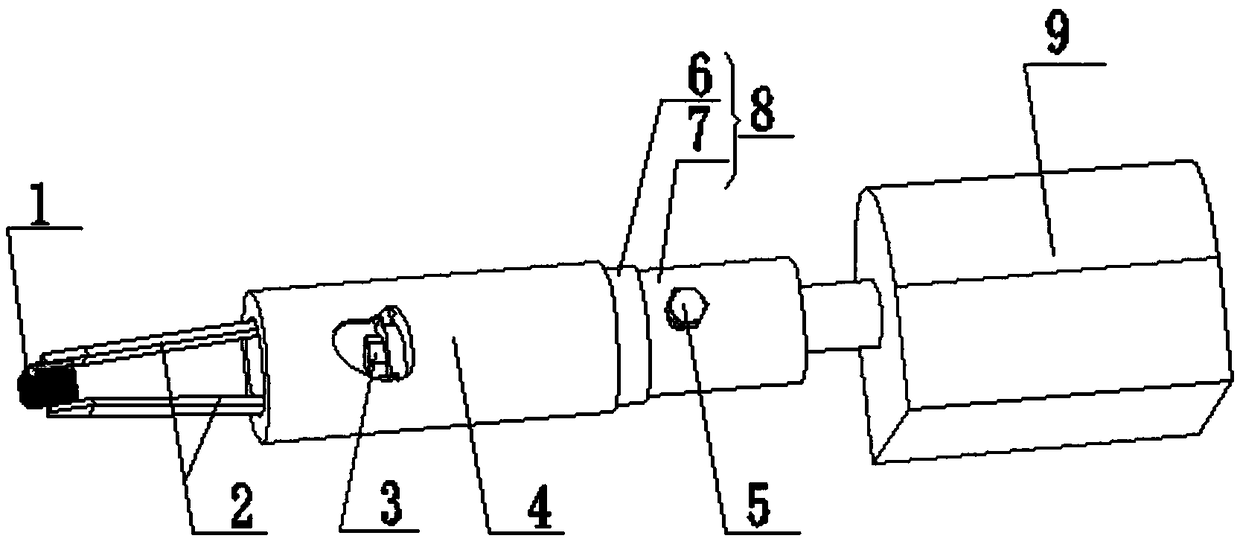

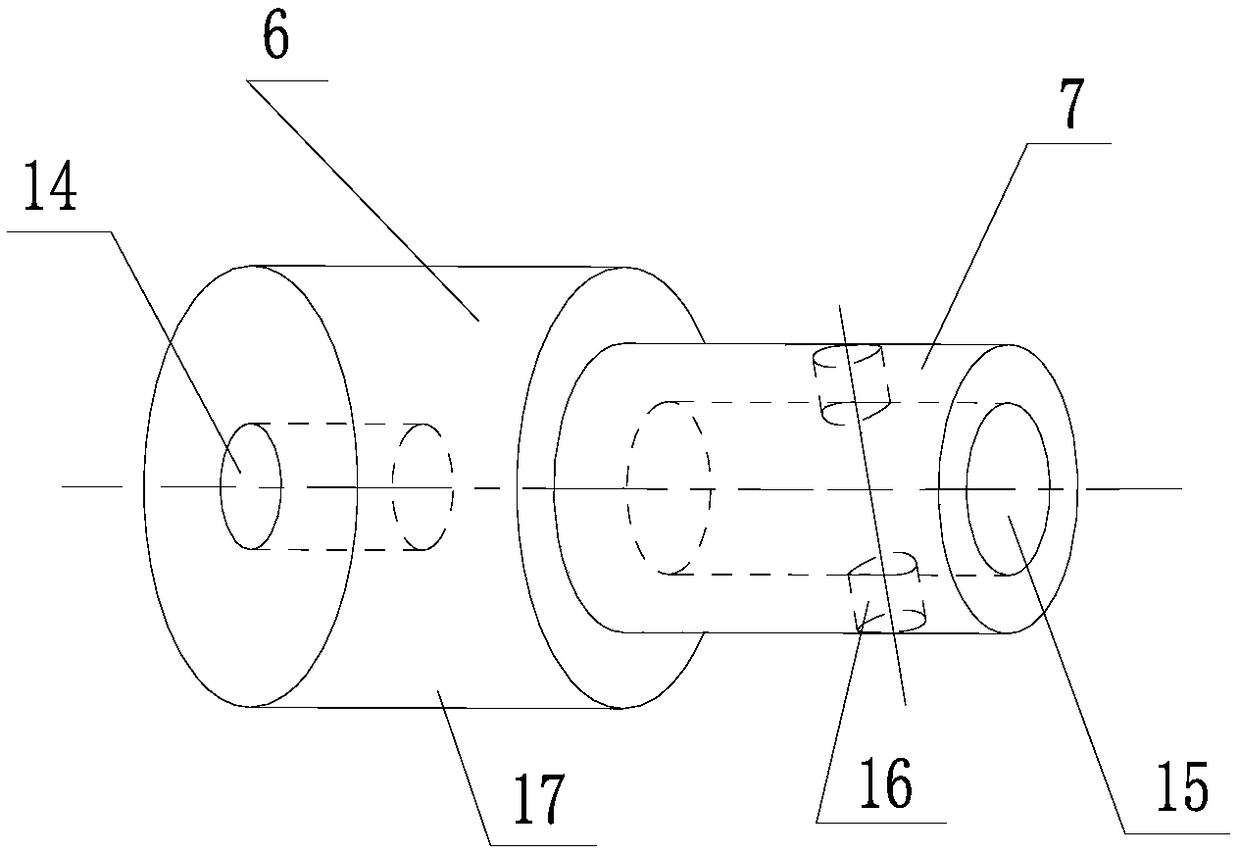

[0020] Please refer to Figure 1 to Figure 5 , the embodiment of the present invention provides an irregular polyhedron non-contact laser processing leaf spring clamp to complete the mechanical clamping of irregular polyhedron material 1, mainly including spring leaf clamp 2, connecting sleeve 8 and rotating fastening sleeve 4 etc. parts.

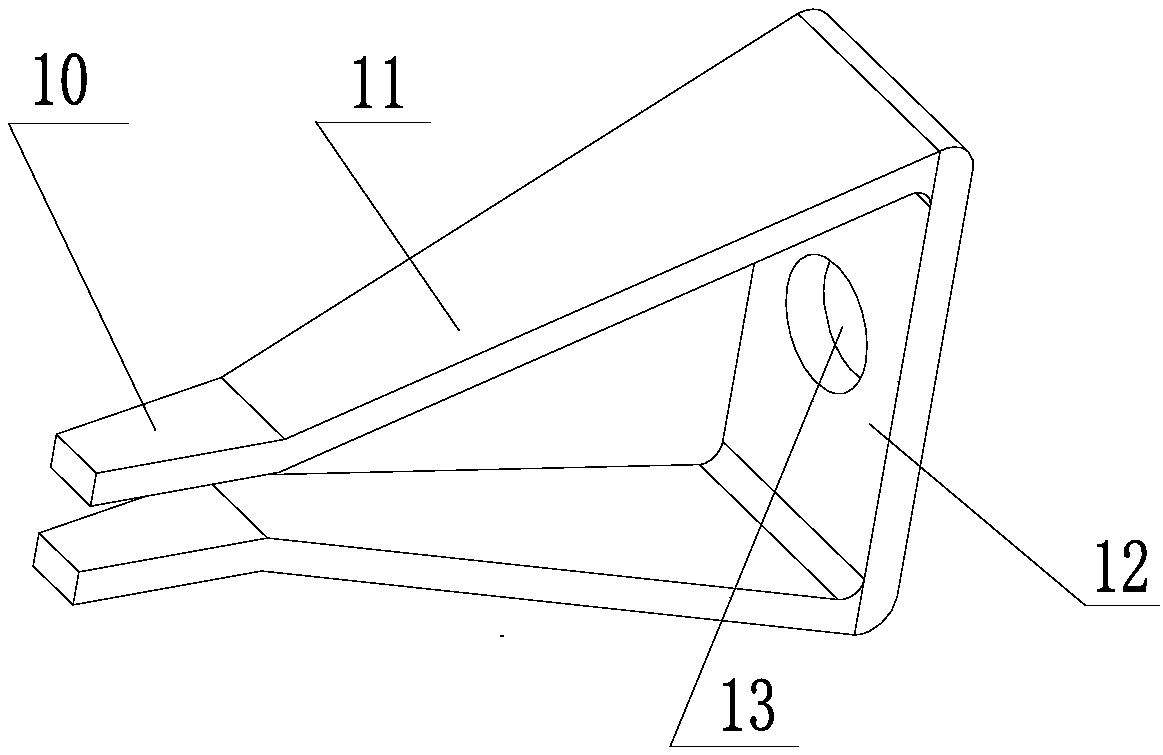

[0021] The leaf spring clip 2 includes a material clamping portion 10, a pressure bearing portion 11 and a connecting portion 12, the material clamping portion 10 is two horizontal clamping petals arranged oppositely, and the pressure bearing portion 11 is the opposite direction of the two clamping petals. Two spring pieces inclined outward, the spring pieces are made of spring steel, and the left end of each spring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap