A steel cylinder derusting device

A technology for steel cylinders and wire brushes, applied in metal processing equipment, grinding workpiece supports, manufacturing tools, etc., can solve the problems of long waiting time and low rust removal efficiency, achieve improved effect, improve rust removal effect, and ensure rough surface degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

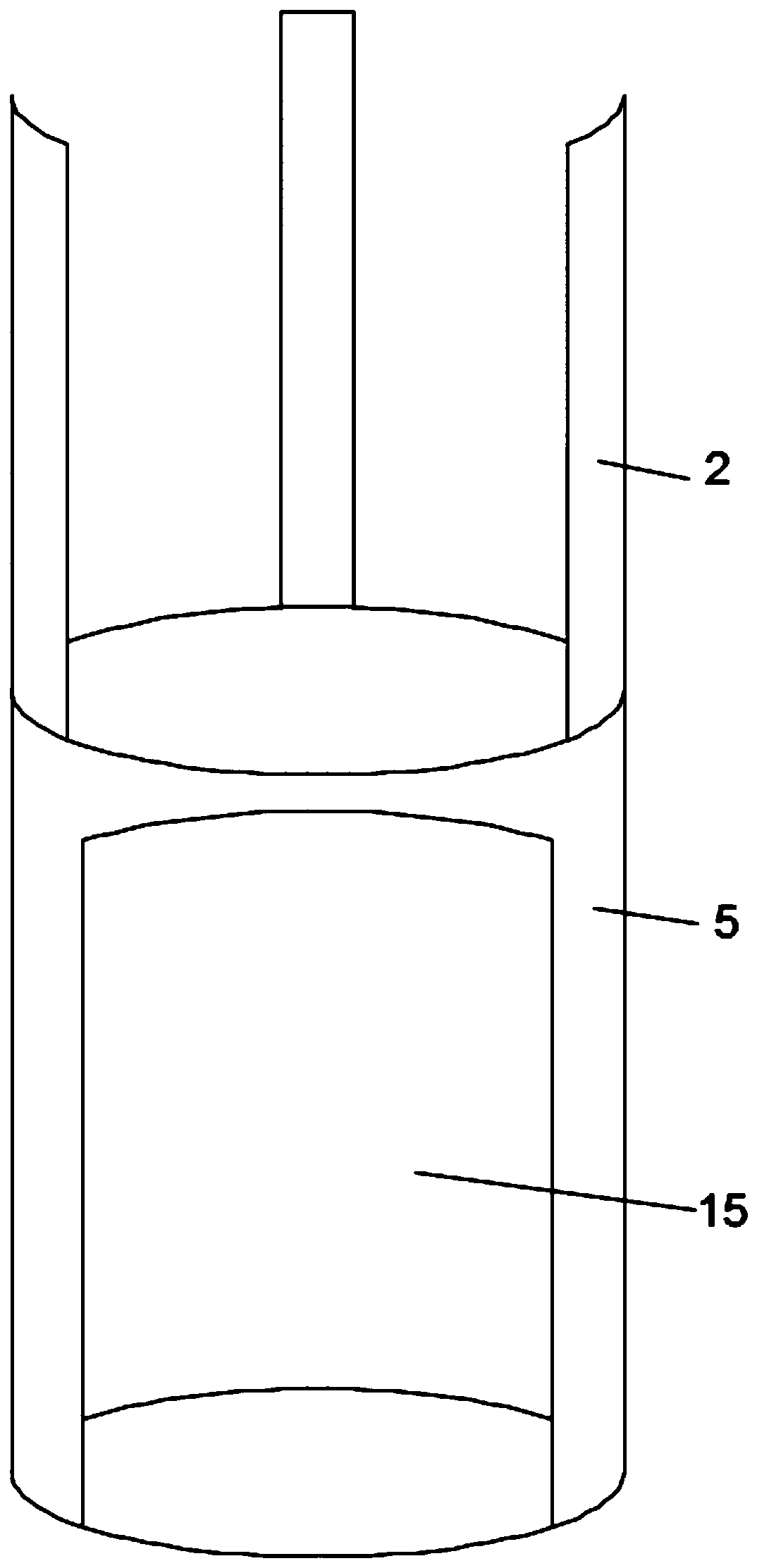

[0030] Such as figure 2 As shown, this embodiment provides a steel cylinder derusting device, which includes a cylinder body 5, and a frame 2 is arranged on the upper part of the cylinder body 5.

[0031] Such as figure 1 As shown, specifically, the top of the frame 2 is fixed with a lifting mechanism 1, the lower end of the lifting mechanism 1 is provided with a rotating assembly 14, the bottom of the rotating assembly 14 is provided with a bearing plate 13, and the bottom of the bearing plate 13 is evenly distributed around the center of the circle. The clamping mechanism 12 of the steel cylinder, the bottom of the cylinder 5 is provided with a rust removal device 1 3 and a rust removal device 2 11 that cooperate with the clamping mechanism 12, and the side wall of the cylinder 5 is provided with a loading port 15 for loading and unloading For steel cylinders, by setting a rotatable bearing plate 13 and three steel cylinder clamping mechanisms 12 at the bottom of the beari...

Embodiment 2

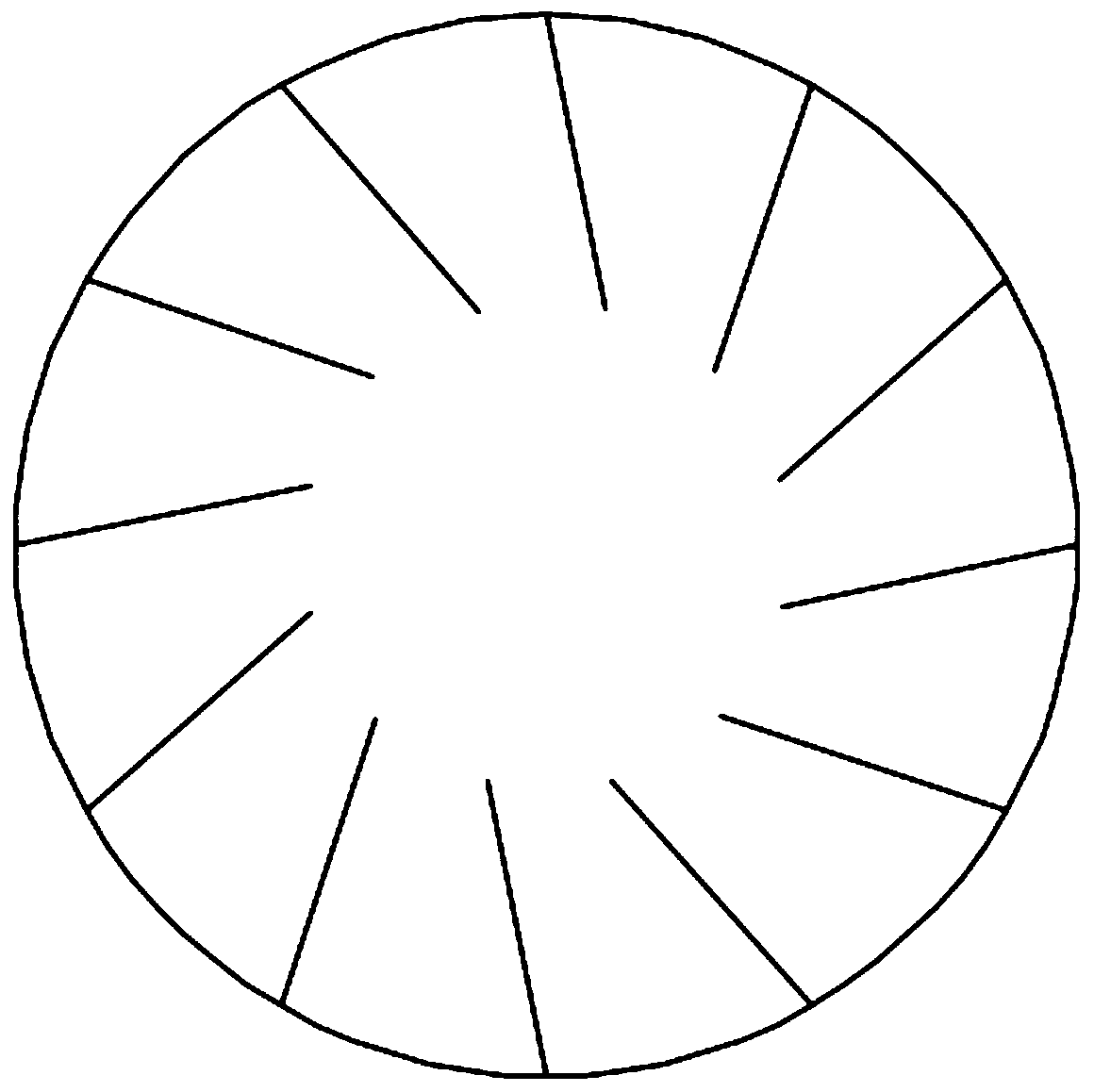

[0038] Such as image 3 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the wire brush 4 includes a number of steel wires evenly distributed on the inner wall of the derusting cylinder 6, and each steel wire is 20 degrees away from the radial direction.

[0039] Set the steel wire at 20 degrees to the radial direction, so that the steel wire is inclined relative to the radial direction, so that the steel cylinder can be inserted into the derusting cylinder 6, and at the same time, when the derusting cylinder 6 rotates, the contact time between the steel wire and the outer wall of the steel cylinder can be increased to improve the efficiency of derusting Effect.

Embodiment 3

[0041] Such as Figure 5 As shown, this embodiment is further optimized on the basis of Embodiment 2. Specifically, a plurality of support blocks 16 are provided on the inner wall of the upper part of the cylinder body 5, and the top of each support block 16 is provided with a limit groove 18, and the edge of the bearing plate 13 A limiting block 17 matched with the limiting groove 18 is provided.

[0042] When the bottom of the bearing plate 13 is in contact with the support block 16, the support block 16 bears the gravity of the steel cylinder, avoiding the cylinder being loaded for a long time and protecting the life of the cylinder. Rotate to prevent the steel cylinder from causing the bearing plate 13 to rotate when derusting in the derusting cylinder 6, causing the device to be unbalanced, thereby affecting the derusting effect.

[0043] Working principle: Start the cylinder, lower the piston rod, load the cylinder armrest on the jaw 122 from the loading port 15, and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com