Repetitive Motion Planning Method for Redundant Robot Using Finite Interval Neural Network

A neural network and repetitive motion technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of unguaranteed motion repeatability, accidents and dangers, and low efficiency, and achieve fast convergence characteristics and high accuracy of closing angles , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The present invention will be further described below in conjunction with the accompanying drawings.

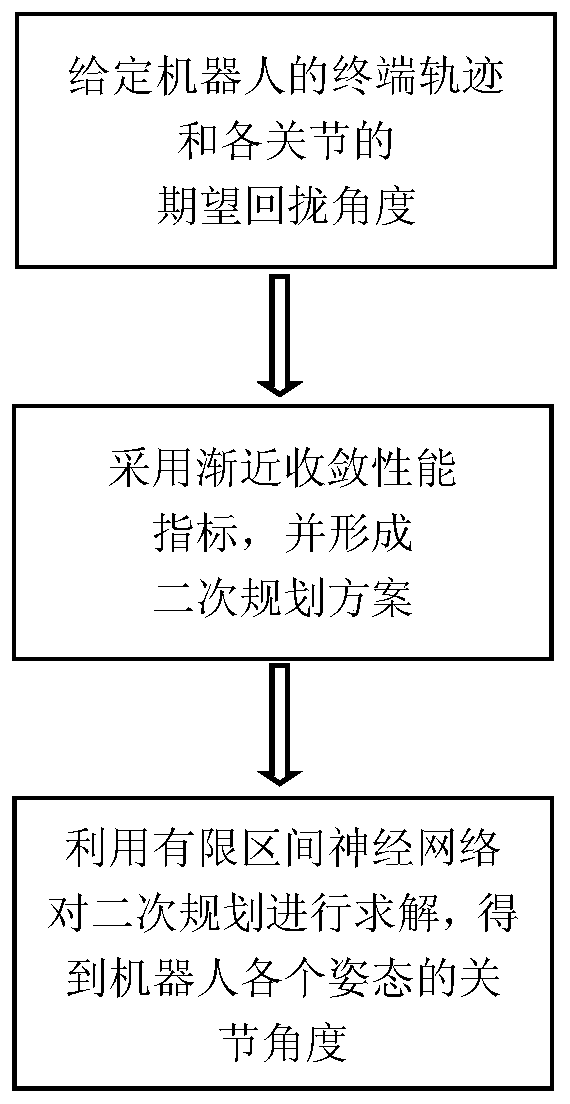

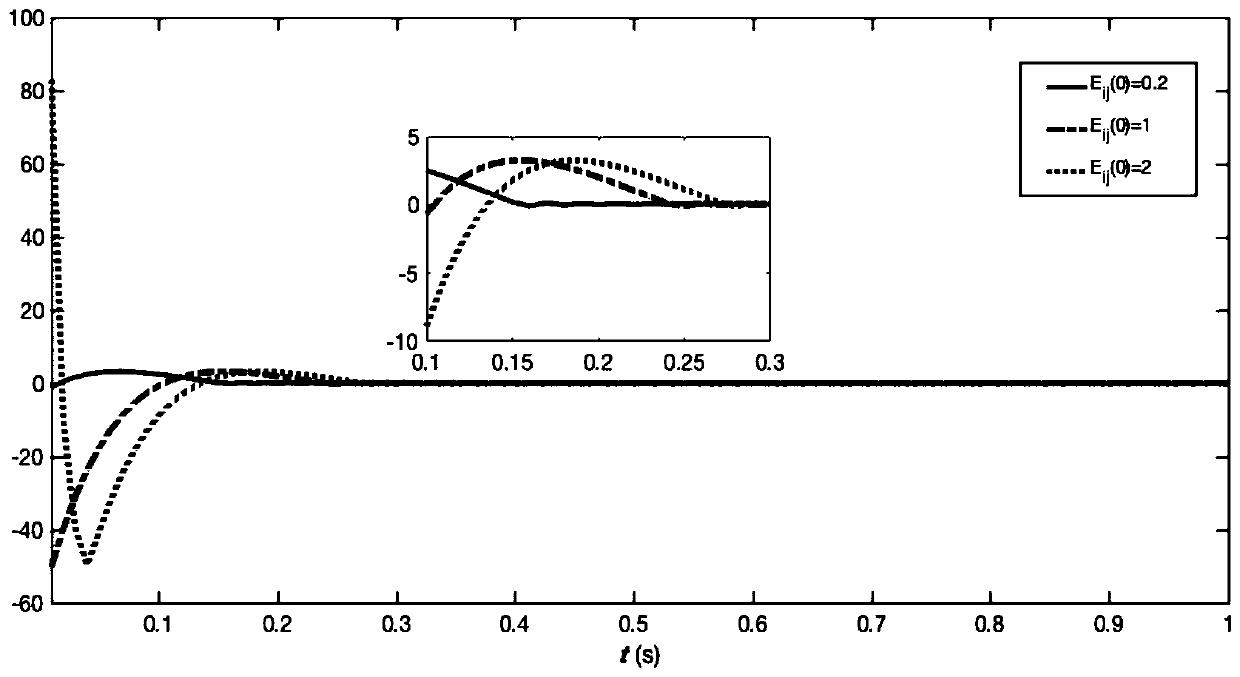

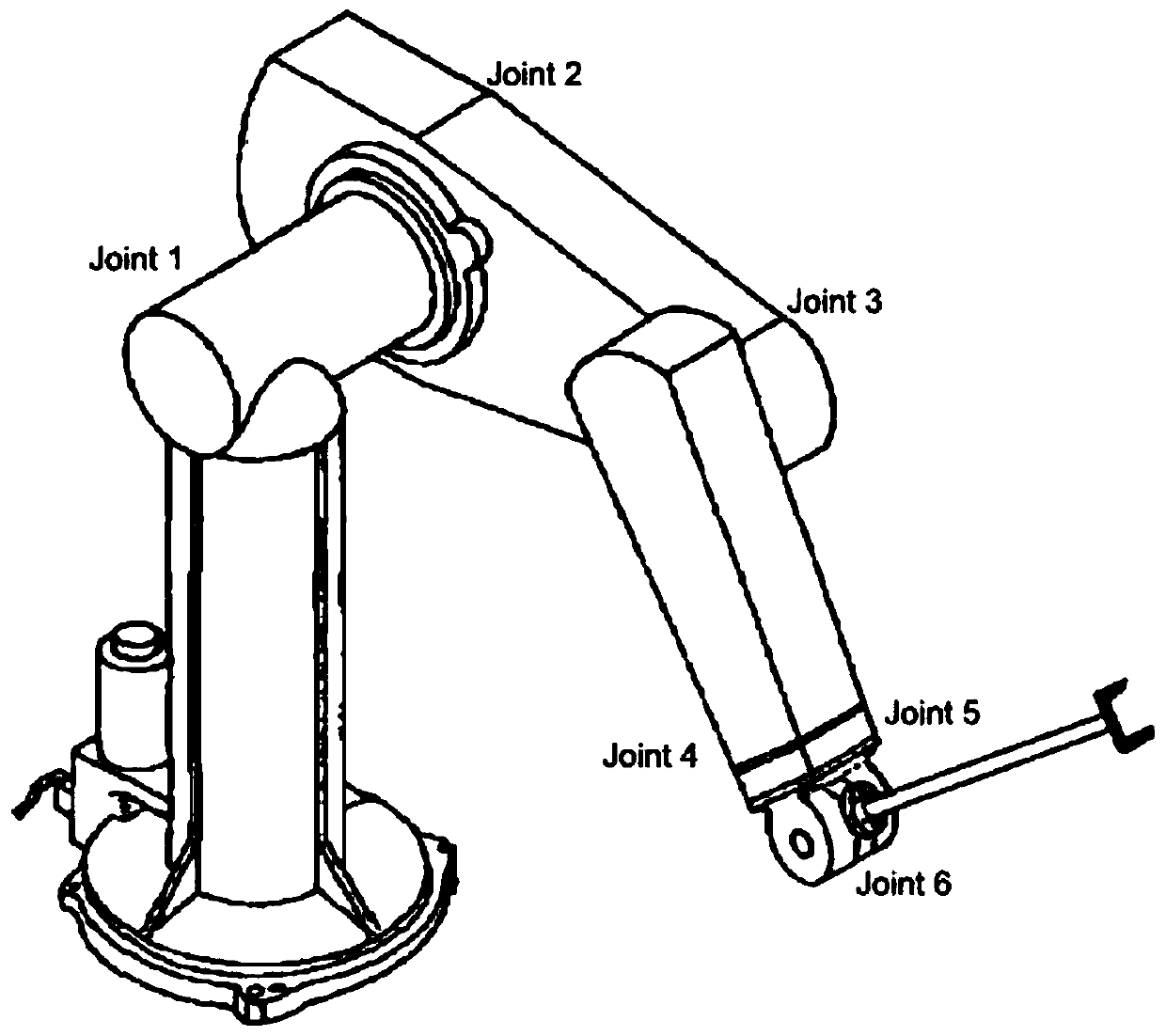

[0091] refer to Figure 1 to Figure 9 , a repetitive motion planning method for redundant robots based on finite interval neural networks, figure 1 The flow chart of the repetitive motion planning scheme for redundant robots consists of the following three steps: 1. Determine the expected trajectory of the redundant robot end effector and the expected angles of each joint; 2. Adopt the asymptotic convergence performance index and form redundant The quadratic planning scheme for the repetitive motion of the robot; 3. Solve the quadratic programming problem with a finite interval neural network to obtain the trajectory of each joint angle, as follows:

[0092] 1) Determine the desired trajectory

[0093] Setting expectations for redundant robots PUMA560 for reunion

[0094] Determine the coordinates of the center of the circle trajectory

[0095] (x=0.2m, y=0, z=0)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com