A kind of water-based inkjet, laser printing dual-purpose medical film and preparation method thereof

A laser printing and water-based inkjet technology, which is applied in the field of medical film, can solve the problems of blurred borders of printed images, non-ink-absorbing coatings, and poor color reproduction, and achieve improved particle accumulation efficiency, enhanced weather resistance, and excellent dry fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

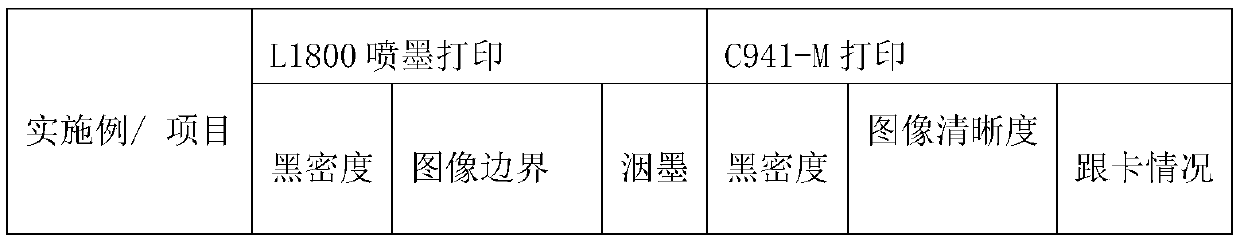

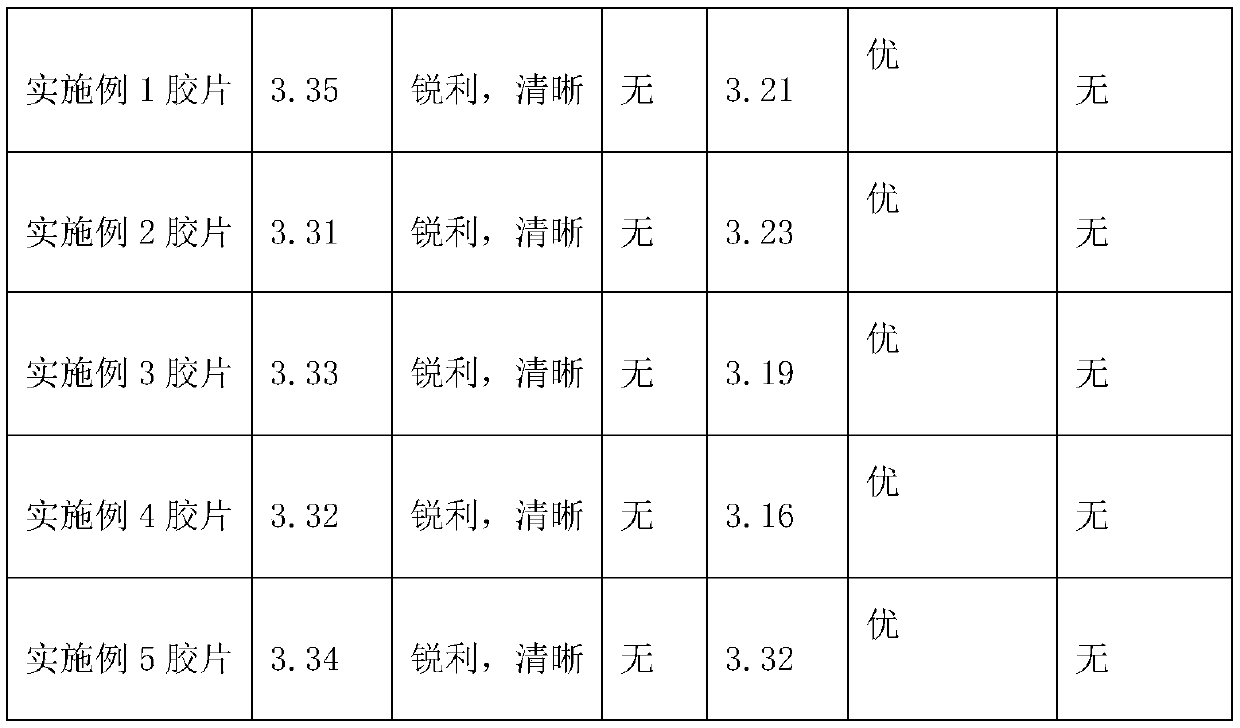

Examples

Embodiment 1

[0034] A water-based inkjet and laser printing dual-purpose medical film, the base material is a PET sheet, and the upper surface of the front of the base material has two layers of coatings: a printing layer and an adhesive layer at the bottom of the printing layer. The back is coated with a functional auxiliary coating,

[0035] The components of the printing layer are 35.21% mixed adhesive, 56.33% mixed inorganic filler, 2% mixed surfactant, 1.16% antioxidant, and 5.3% deionized water. The mixed adhesive is composed of water-based polyurethane, water-based acrylic resin and Polyvinyl alcohol aqueous solution, and the mass ratio of the three is 1:1:5, the mixed inorganic filler is composed of inorganic nano compound particles and inorganic micron compound particles, the mass ratio of the two is 2:3, and the Beijing De Combination of 20nm silica from Kedaojin Technology Co., Ltd. and 7μm H907 silica from Beijing Huacong Economic and Trade Co., Ltd. The mixed surfactant is alk...

Embodiment 2

[0045] A water-based inkjet and laser printing dual-purpose medical film, the base material is a PET sheet, and the upper surface of the front of the base material has two layers of coatings: a printing layer and an adhesive layer at the bottom of the printing layer. The back is coated with a functional auxiliary coating,

[0046] The formula of the printing layer is mixed adhesive 35.21%, mixed inorganic filler 56.33%, mixed surfactant 2%, antioxidant 1.16%, deionized water 5.3%, mixed adhesive is composed of water-based polyurethane, water-based acrylic resin and polyethylene Alcohol aqueous solution, and the mass ratio of the three is 1:1:5. The mixed inorganic filler is composed of inorganic nano compound particles and inorganic micron compound particles, and the mass ratio of the two is 2:3. Example 2 uses Beijing Deke Island The 20nm silicon carbide of Jin Technology Co., Ltd. is combined with the 7μm H907 silicon dioxide of Beijing Huacong Economic and Trade Co., Ltd. T...

Embodiment 3

[0051] A water-based inkjet and laser printing dual-purpose medical film, the base material is a PET sheet, and the upper surface of the front of the base material has two layers of coatings: a printing layer and an adhesive layer at the bottom of the printing layer. The back is coated with a functional auxiliary coating,

[0052] The formula of the printing layer is mixed adhesive 35.21%, mixed inorganic filler 56.33%, mixed surfactant 2%, antioxidant 1.16%, deionized water 5.3%, mixed adhesive is composed of water-based polyurethane, water-based acrylic resin and polyethylene Alcohol aqueous solution, and the mass ratio of the three is 1:1:5. The mixed inorganic filler is composed of inorganic nano compound particles and inorganic micron compound particles, and the mass ratio of the two is 2:3. Example 3 uses Beijing Deke Island 20nm zirconia from Jin Technology Co., Ltd., 7μm H907 silica filler combination from Beijing Huacong Economic and Trade Co., Ltd., the mixed surfact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com