Pre-cooling type air inlet and hypersonic speed aircraft

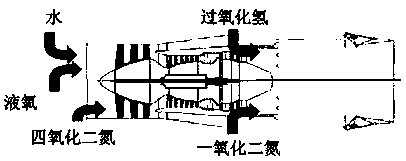

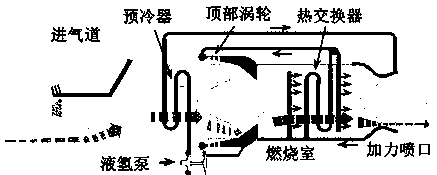

An air inlet and pre-cooling technology, which is applied to the combustion of the air inlet of the power unit, aircraft parts, and power units on the aircraft, etc., can solve the problems of heavy engine weight, complex structure, and large pressure loss, and improve the compression efficiency. and pressure ratio, increase the heat exchange area, improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

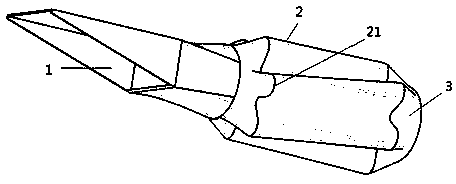

[0036] Please refer to figure 1 , the present invention provides a pre-cooling air inlet, including an inlet section 1, a pre-cooling section 2 and a transition section 3 connected in sequence, wherein:

[0037] The inlet section 1 is used for inhaling airflow; the bottom has an air inlet, and the two sides are wedge-shaped;

[0038] The pre-cooling section 2 is in the shape of a cylinder, and a plurality of distribution channels 21 are distributed in the circumferential direction for the incoming gas to rotate according to a preset angle. All the distribution channels 21 are connected to each other. The depth of the distribution channels 21 is The direction is along the radial direction of the cross-section of the pre-cooling section; the inner wall of the pre-cooling section 2 has a number of convex heat exchange cells 23, and a cooling channel for the circulation of the cooling medium is formed between the outer wall and the inner wall of the pre-cooling section 22. The le...

Embodiment 2

[0051] Please refer to Figure 7 , and the difference from Embodiment 1 is that the distribution channel 21 is in a rotating shape along the radial direction of the pre-cooling section 3 and rotates in the same direction. Radial rotation through the shunt channel 21 (see Figure 7 Arrow direction) to form a pre-swirling airflow, which is suitable for inlets with large radial dimensions.

Embodiment 3

[0053] An embodiment of the present invention is also a hypersonic aircraft, including a compressor and the pre-cooling air inlet of any of the above embodiments, the transition section 3 of the pre-cooling air inlet is connected to the air inlet of the compressor. The beneficial effect is the same as that of the above-mentioned pre-cooling air intake channel, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com