Double-pump double-spraying heavy-scale water jet loom

A water-jet loom, heavyweight technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as inability to weave fabrics, and achieve the effects of low price, wide adaptability and rich varieties of weaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

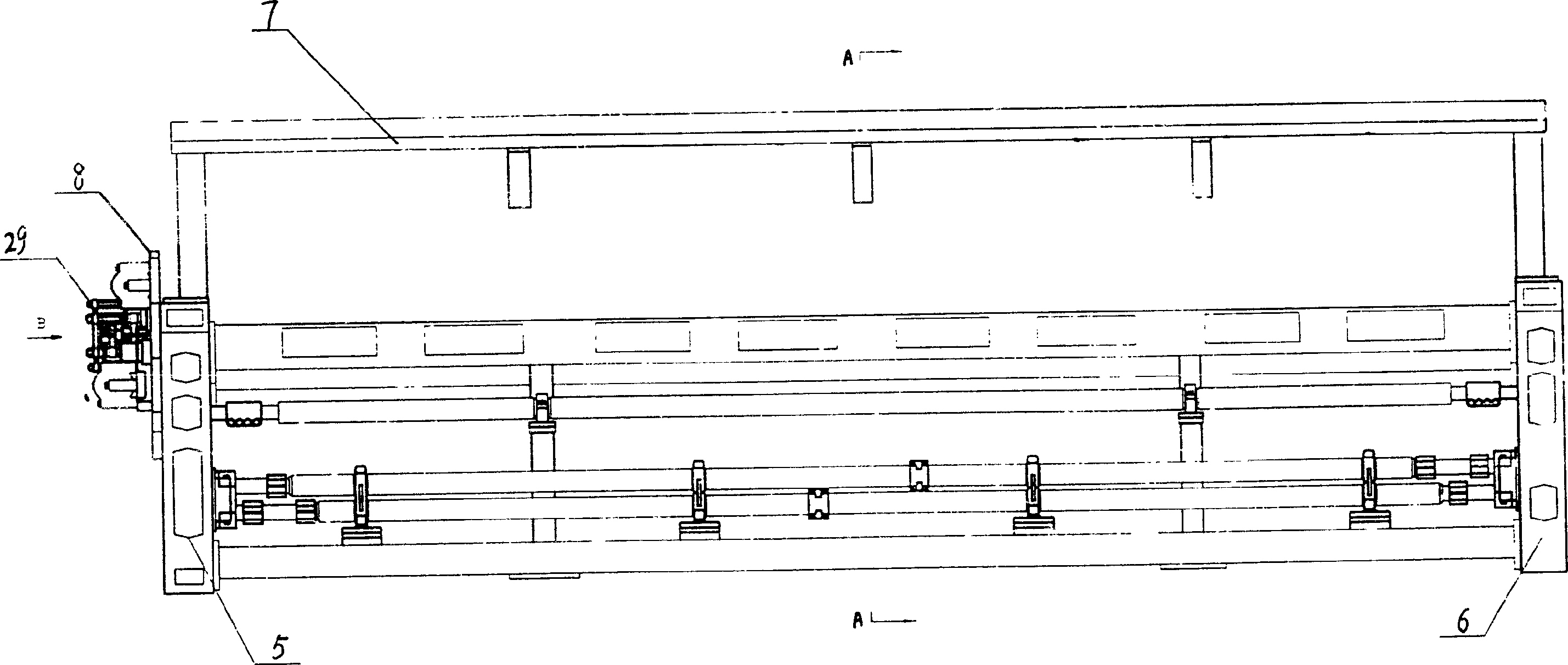

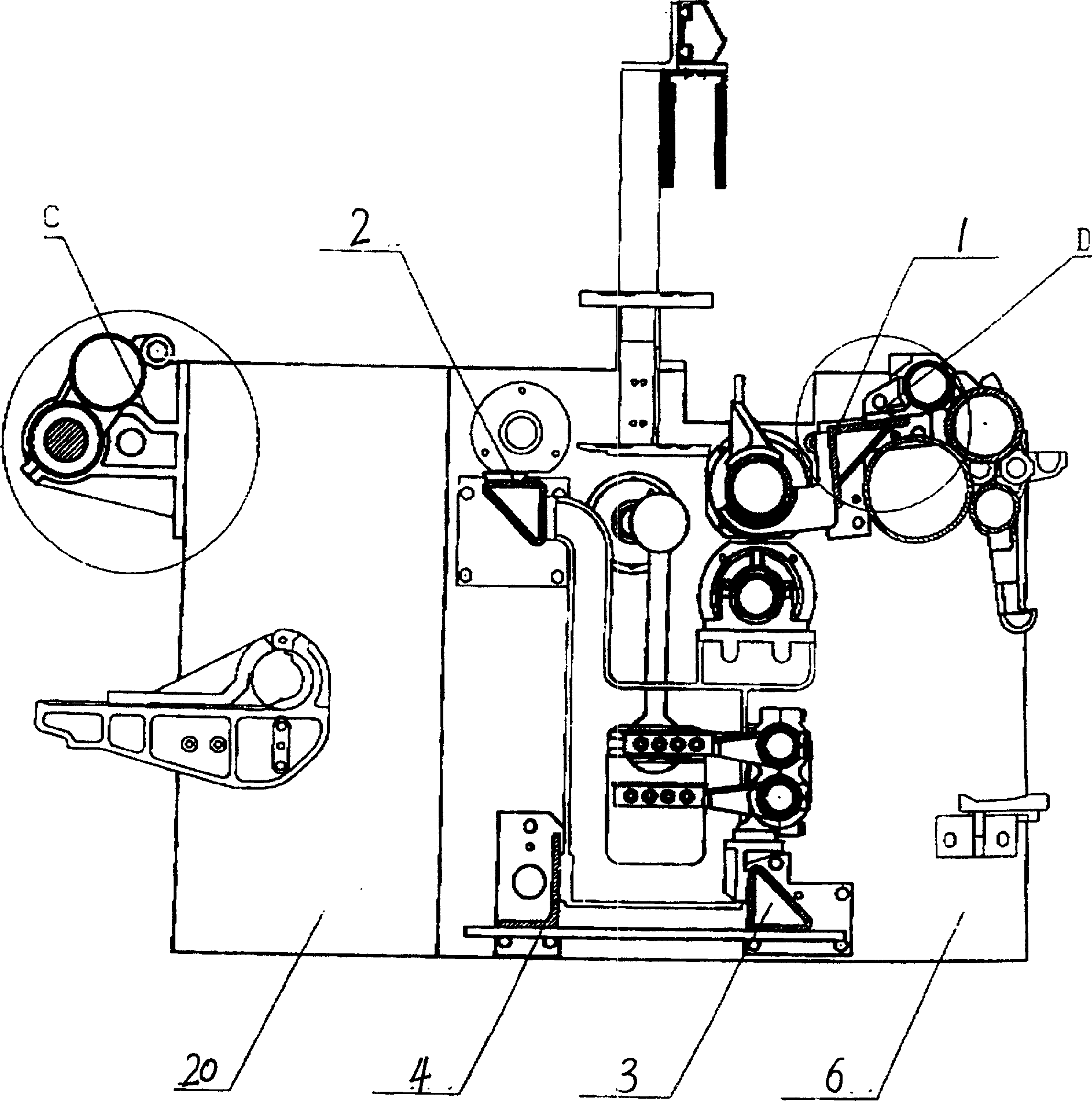

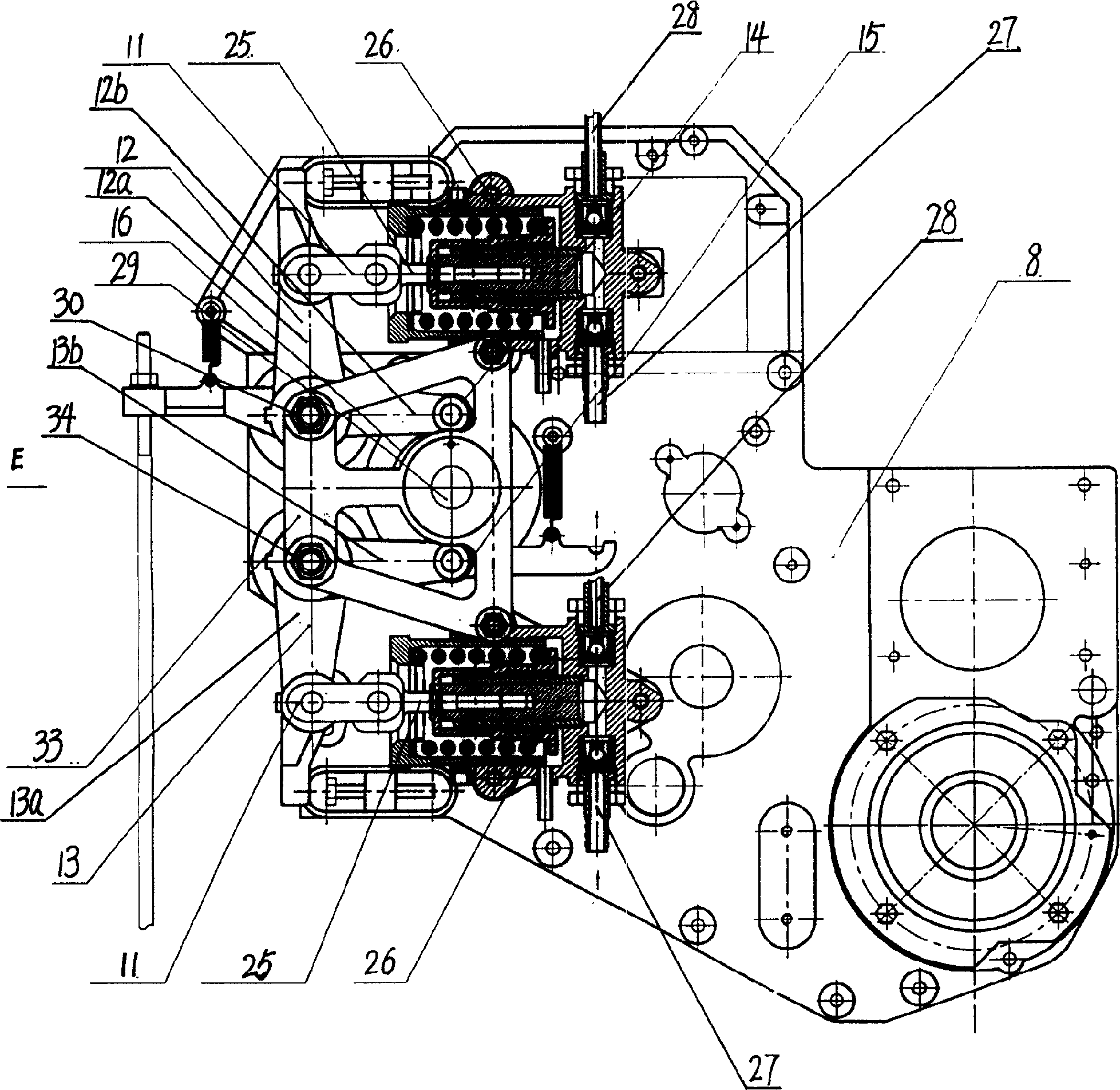

[0020] Such as figure 1 , figure 2 , image 3 , Figure 6 As shown, the present invention comprises a frame 7 made up of a front upper beam 1, a rear upper beam 2, a front lower beam 3, a rear lower beam 4, a left wall panel 5, a right wall panel 6, and a let-off rear wall panel 20. The outside of the wallboard 5 is connected with a left side cover 8, and the left side cover 8 is fastened and connected with an upper water pump 9 and a lower water pump 10. Between 10 and the left side cover 8, there is also a lower pump support 31, and the upper water pump 9 and the lower water pump 10 are all mainly composed of plunger joint 25, plunger 26, water inlet pipe 27, and water outlet pipe 28. The upper water pump 9 and the lower water pump 10 are respectively connected to the upper pump cam connecting rod 12 and the lower pump cam connecting rod 13 through the connecting piece 11. The upper pump cam connecting rod 12 and the lower pump cam connecting rod 13 are all double-rod mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com