Needle selection and auxiliary thread regulation knitting machine element of knitting jacquard circular knitting machine

A technology of circular weft machine and needle selection, which is applied in knitting, weft knitting, textile and paper making, etc., can solve problems such as machine running speed affecting the service life of the whole machine, difficult control of movement stability, and limitation of the range of weavable varieties. Achieve the effect of stable and smooth weaving, easy quality control and reduction of vibration waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

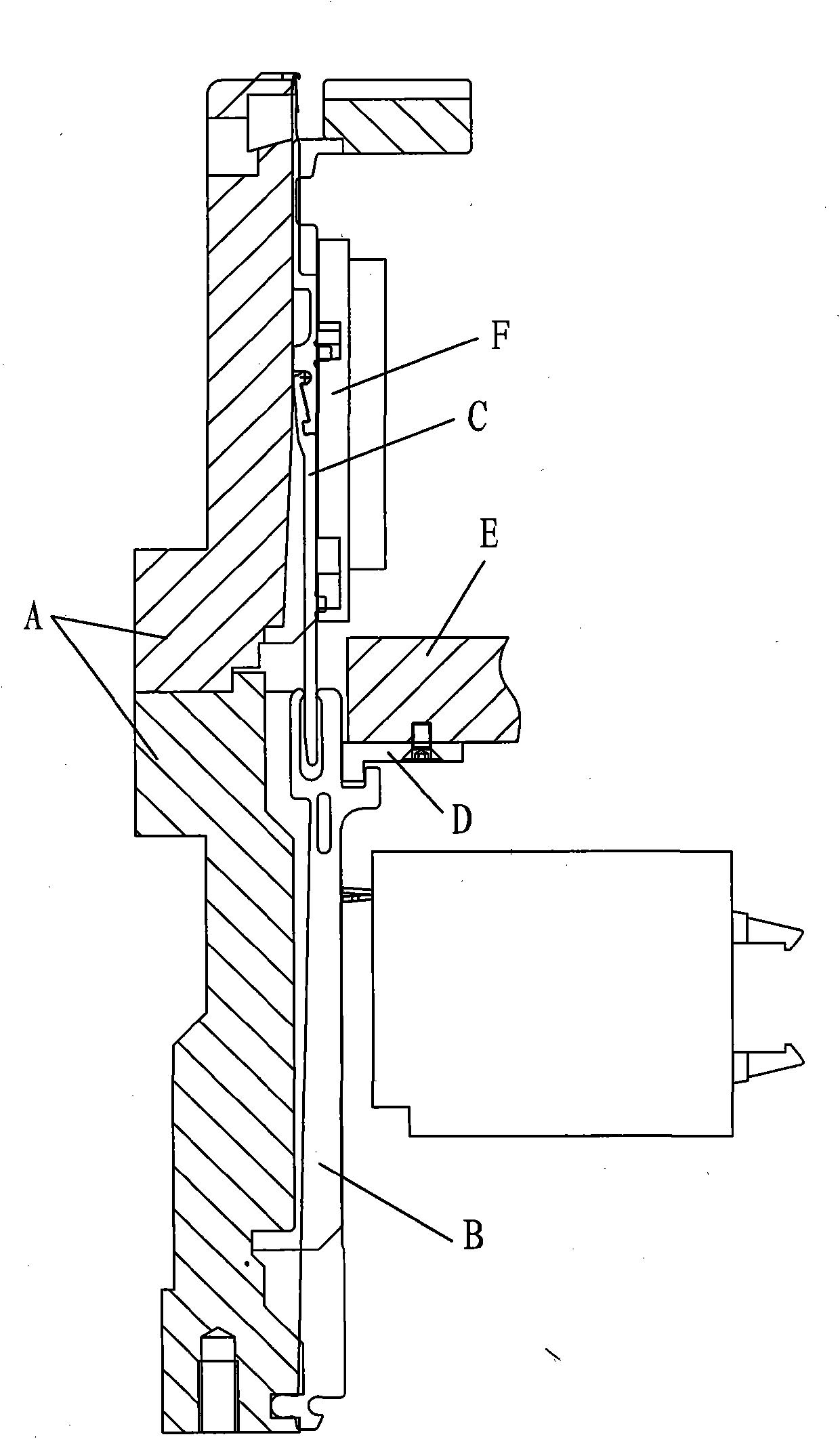

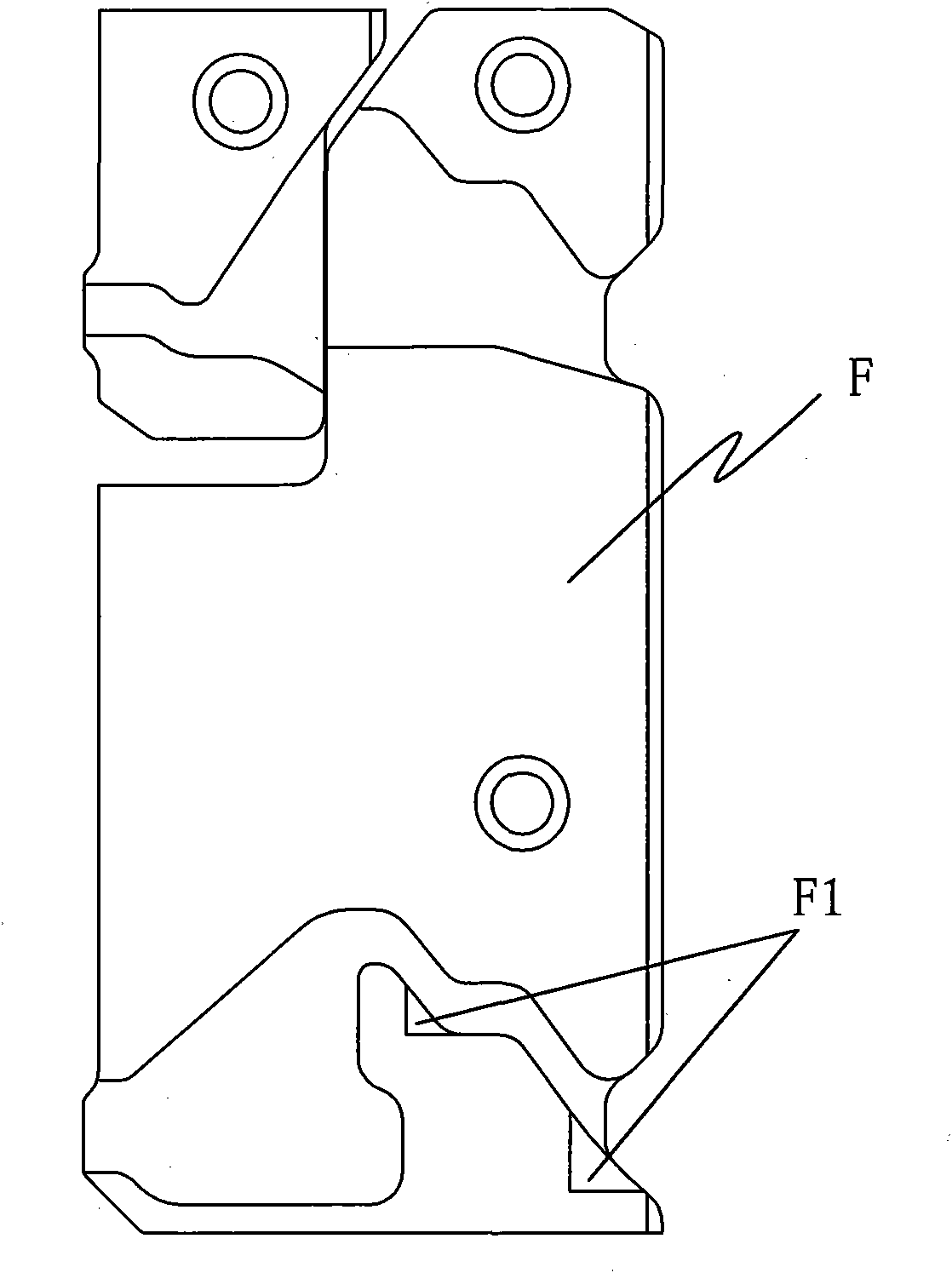

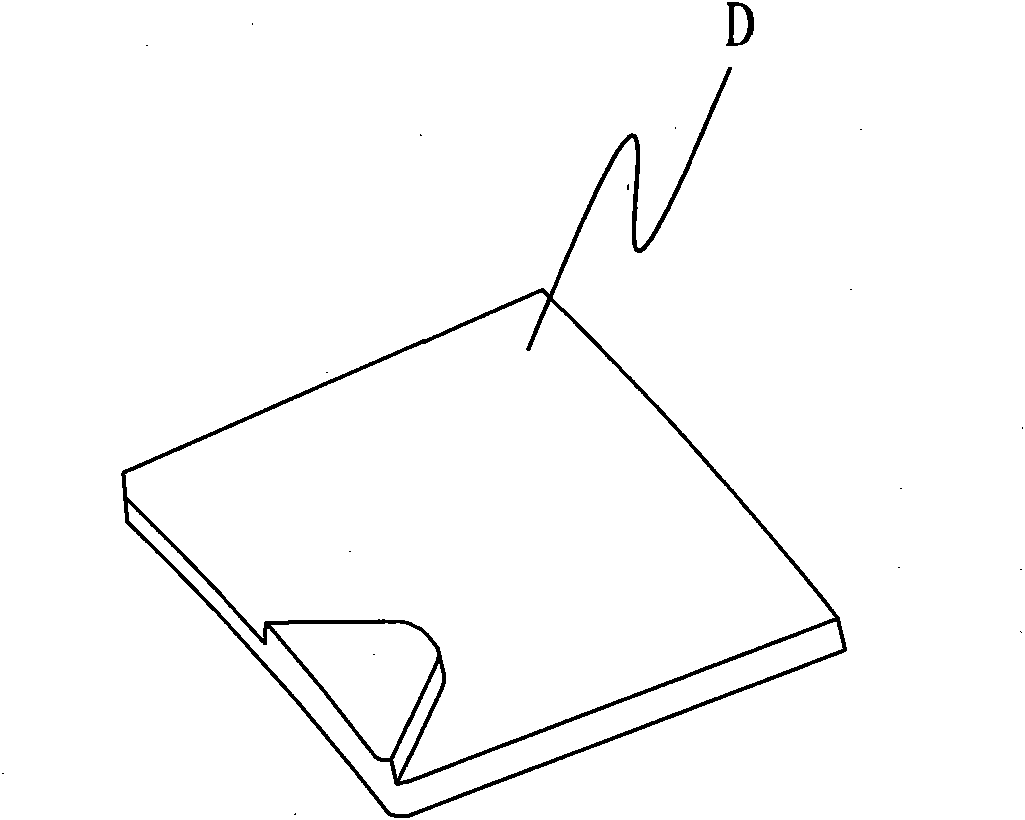

[0029] Example: Structure as figure 2 , image 3 , Figure 4 and Figure 5 As shown, a needle selection mechanism and an auxiliary thread adjusting mechanism of a knitting jacquard circular weft machine include a needle cylinder 4, a return positioning cam 3, a saddle bottom ring 5, an auxiliary intermediate needle 8 and a new needle jack cam 7, a needle cylinder There are knitting needles 6, needle jacks 2 and jacquard pieces 1 inserted from top to bottom in each of the needle grooves. The jacquard piece 1 is in effective contact with one of the blades of the needle selector to perform the needle selection action, and the reset positioning cam 3 is installed On the saddle bottom ring 5, the other side end of the return positioning triangle 3 is arranged on the upper side of the jacquard sheet 1 and is positioned in cooperation with the jacquard sheet, wherein, for example, Figure 7 , the reset position of the reset positioning triangle 3 is provided with a triangular gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com