Adaptive food purifier with grouping type purification cabin, and control method for adaptive food purifier

A technology of a food purifier and a control method, applied in food processing, application, household appliances, etc., can solve the problems of protective shutdown, easy heat generation, poor user experience, etc., to ensure purification efficiency, increase complexity, and good purification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

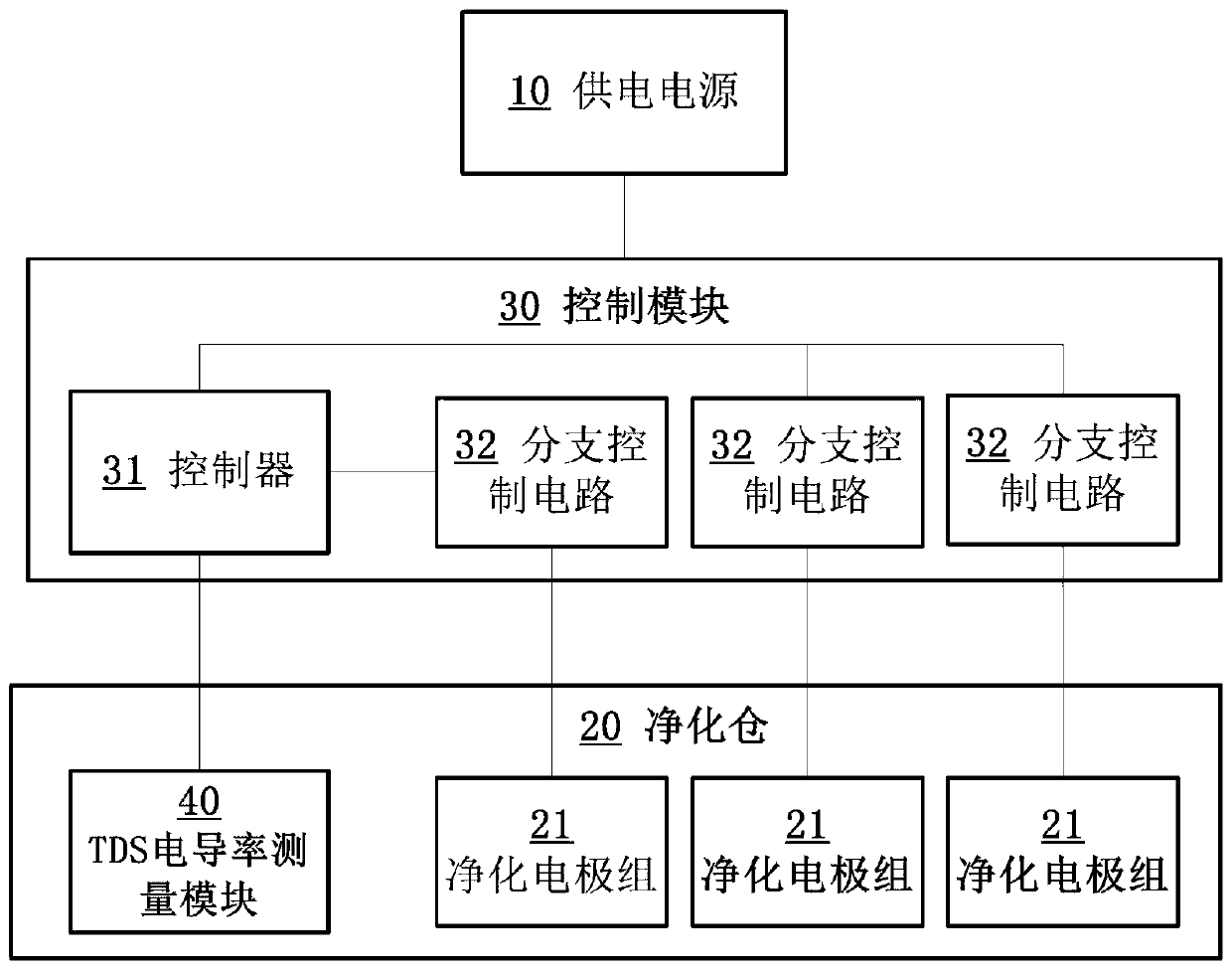

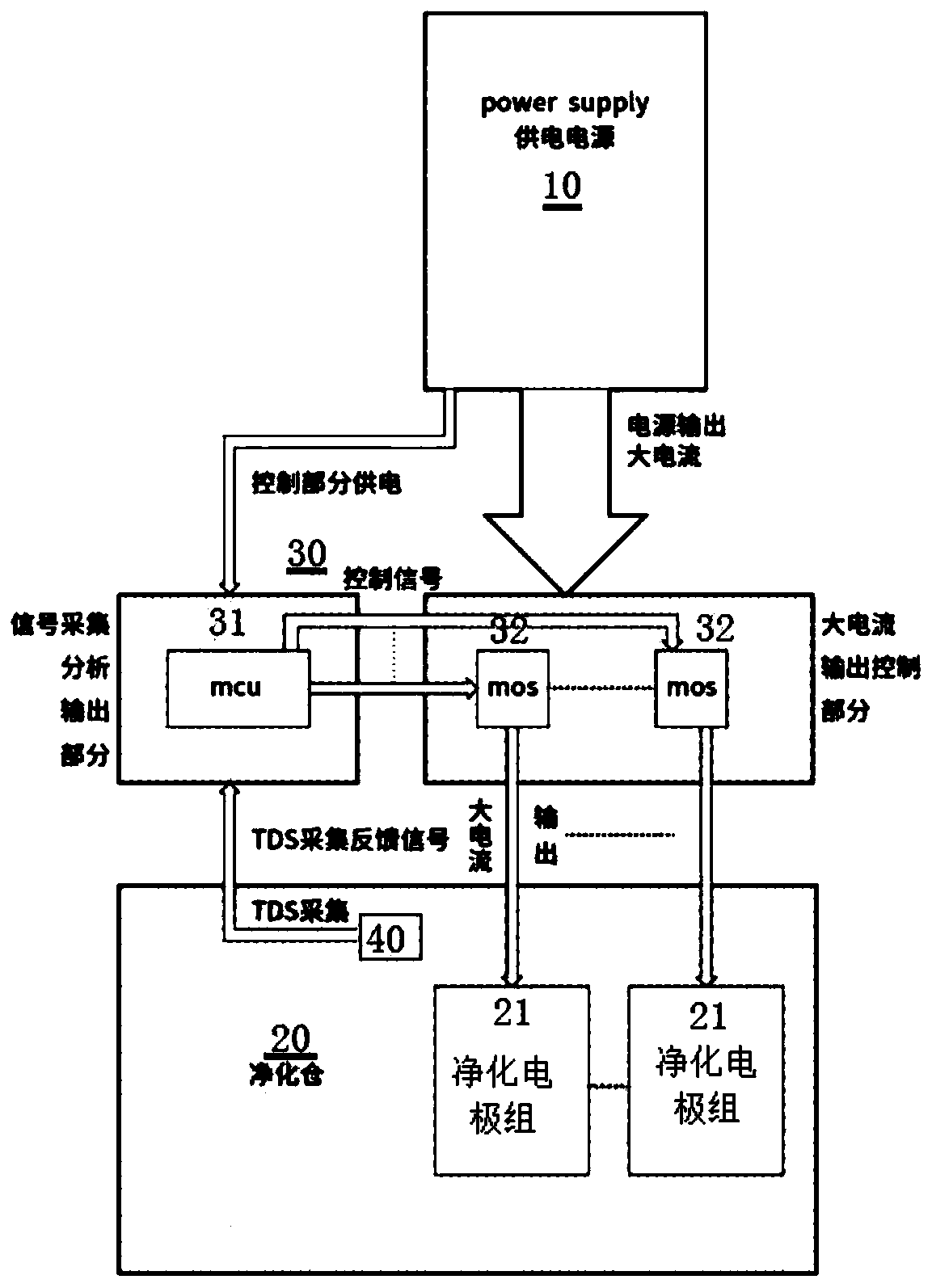

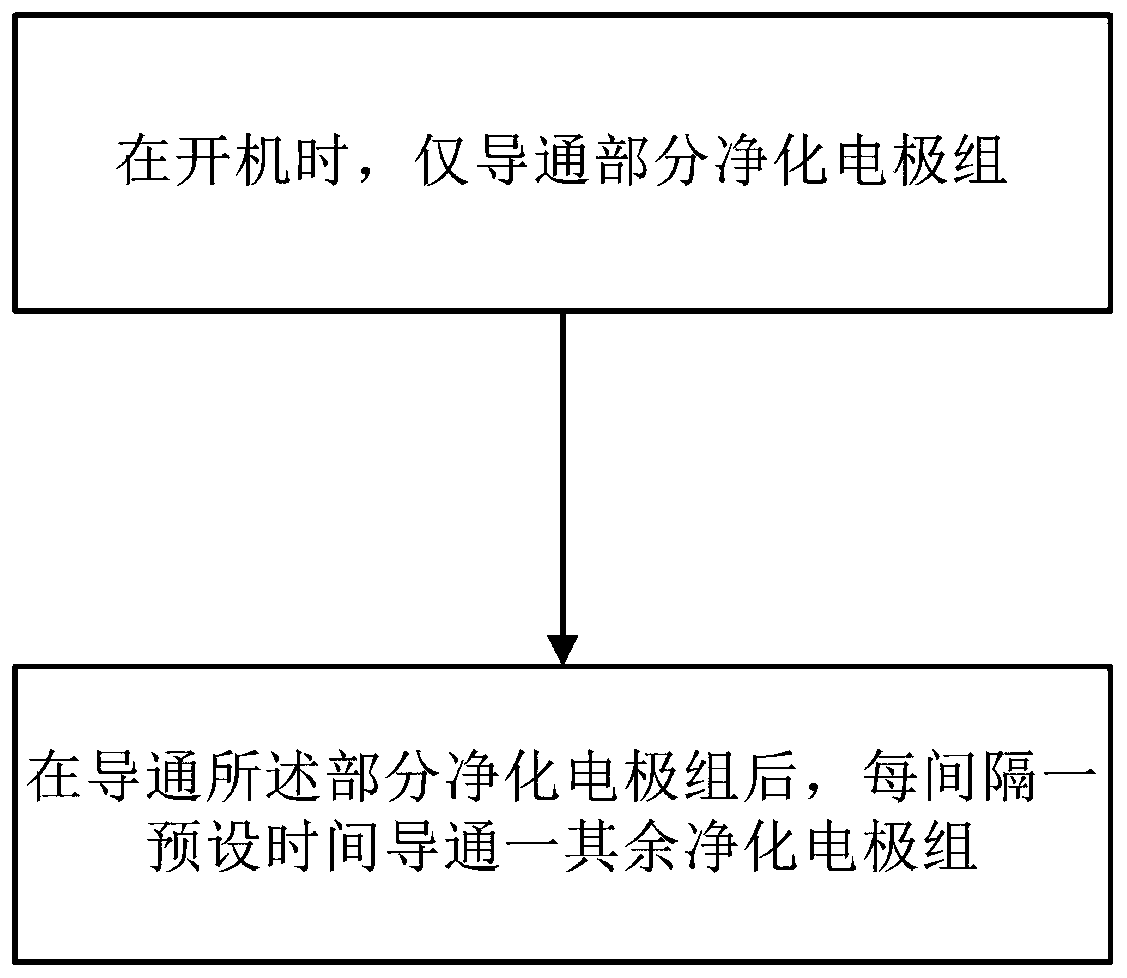

[0039] figure 1 It is a schematic structural block diagram of an adaptive food purification machine with grouped purification bins according to an embodiment of the present application. figure 2 yes figure 1 Schematic schematic of an adaptive food purifier with grouped decontamination bins is shown. Such as figure 1 shown, see also figure 2 , this embodiment provides an adaptive food purification machine 100 with grouped purification chambers, which is a polarization type purification machine, and generally includes: a power supply 10 , a purification chamber 20 and a control module 30 . The power supply 10 is used to supply power to the control module 30 and the purification chamber 20 . The purification chamber 20 is a grouping type purification chamber with a plurality of purification electrodes for placing in water containing food to purify the food under power-on state. The plurality of purification electrodes are divided into a plurality of purification electrode g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com