Automatic storage device for arranging robots

A robot and automatic technology, applied in storage devices, transportation and packaging, etc., can solve problems such as unfavorable intelligent management and control, cost increase, secondary pollution of products, etc., to facilitate intelligent management and control, avoid secondary pollution, and solve The effect of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now, the present invention will be further described in detail in conjunction with the accompanying drawings and preferred embodiments.

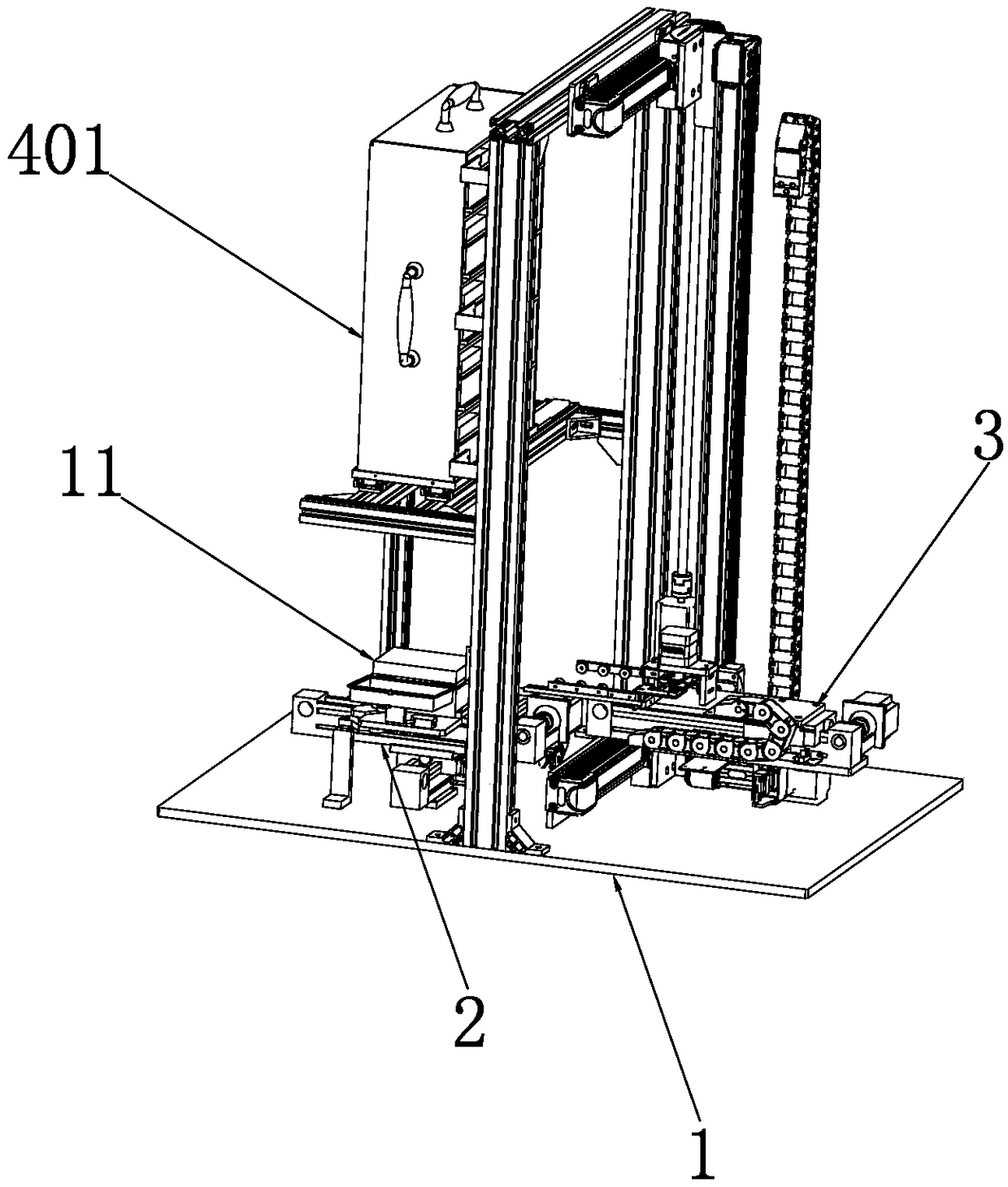

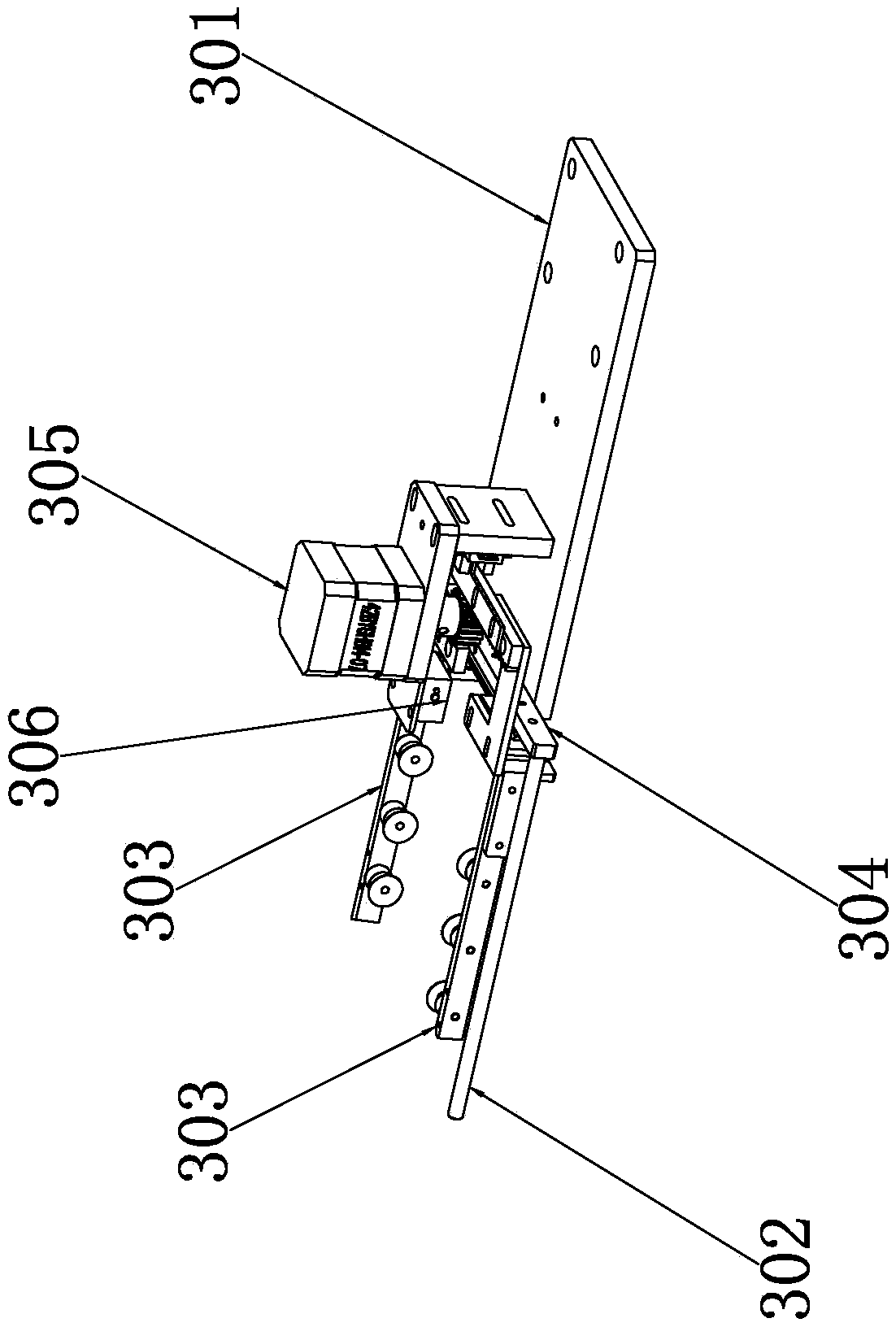

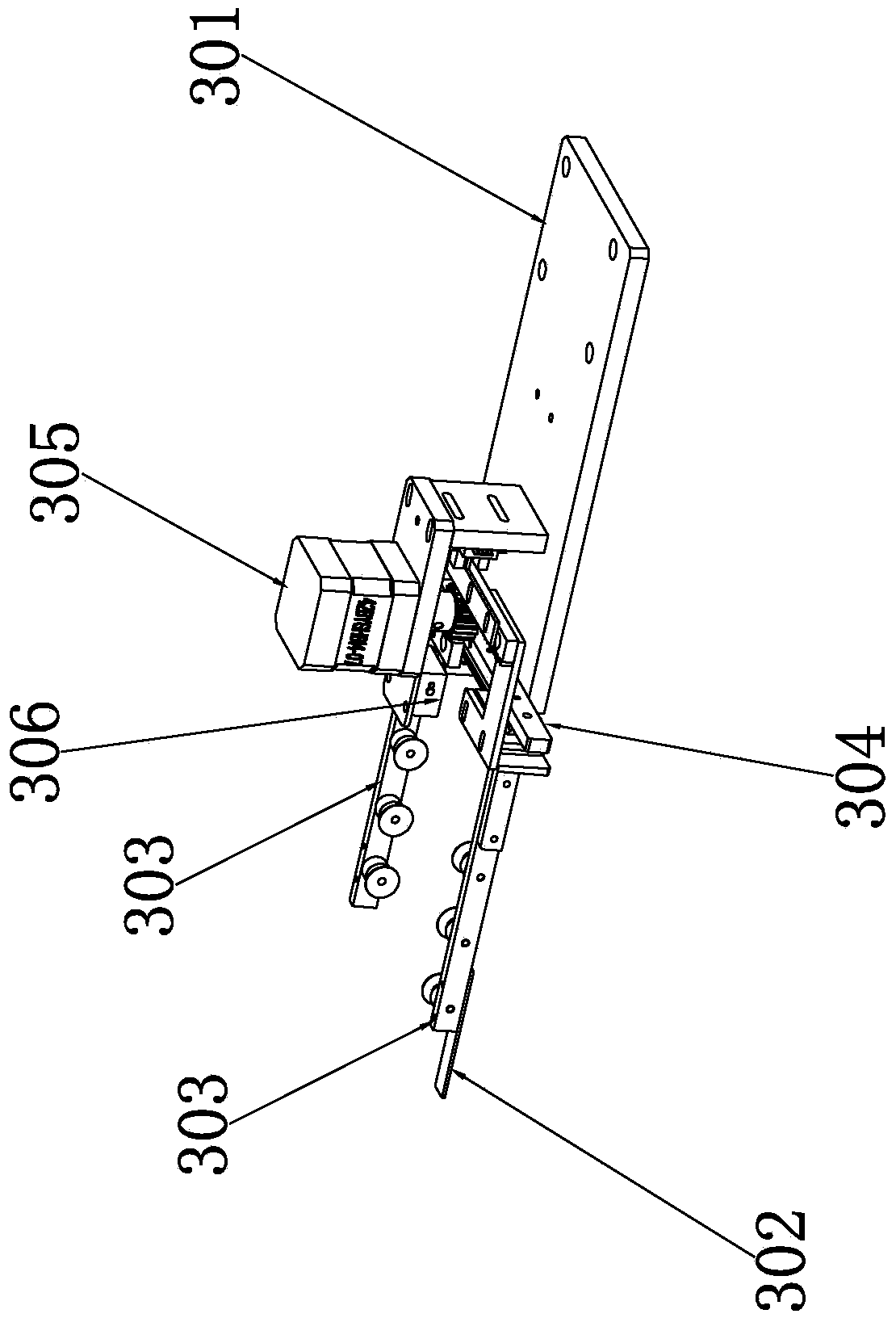

[0022] Such as figure 1 The shown automatic storage device for arranging robots includes a base 1 and an electrical control system. The electrical control system includes a programmable logic controller or a PLC controller or a single-chip microcomputer. The base 1 is also provided with operating components 2, The material shifting component 3 and the storage component, the material moving component 3 is used for carrying the loading box 11 .

[0023] Such as Figure 5 and Figure 6 As shown, the working assembly 2 includes a second bottom plate 201 movably arranged on the base 1, a first stop block 202 and a clamping assembly respectively arranged on the second bottom plate 201, and the clamping assembly can To move closer to and away from the first limiting block 202, preferably, the first limiting block 202 is an L-shaped struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com