Bin body and support structure fused loading station steel structured frame

A supporting structure and loading station technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of increasing the cross-section of columns and beams, and increasing the cost of structural frames, so as to reduce steel consumption, improve reliability, and enhance bearing capacity effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

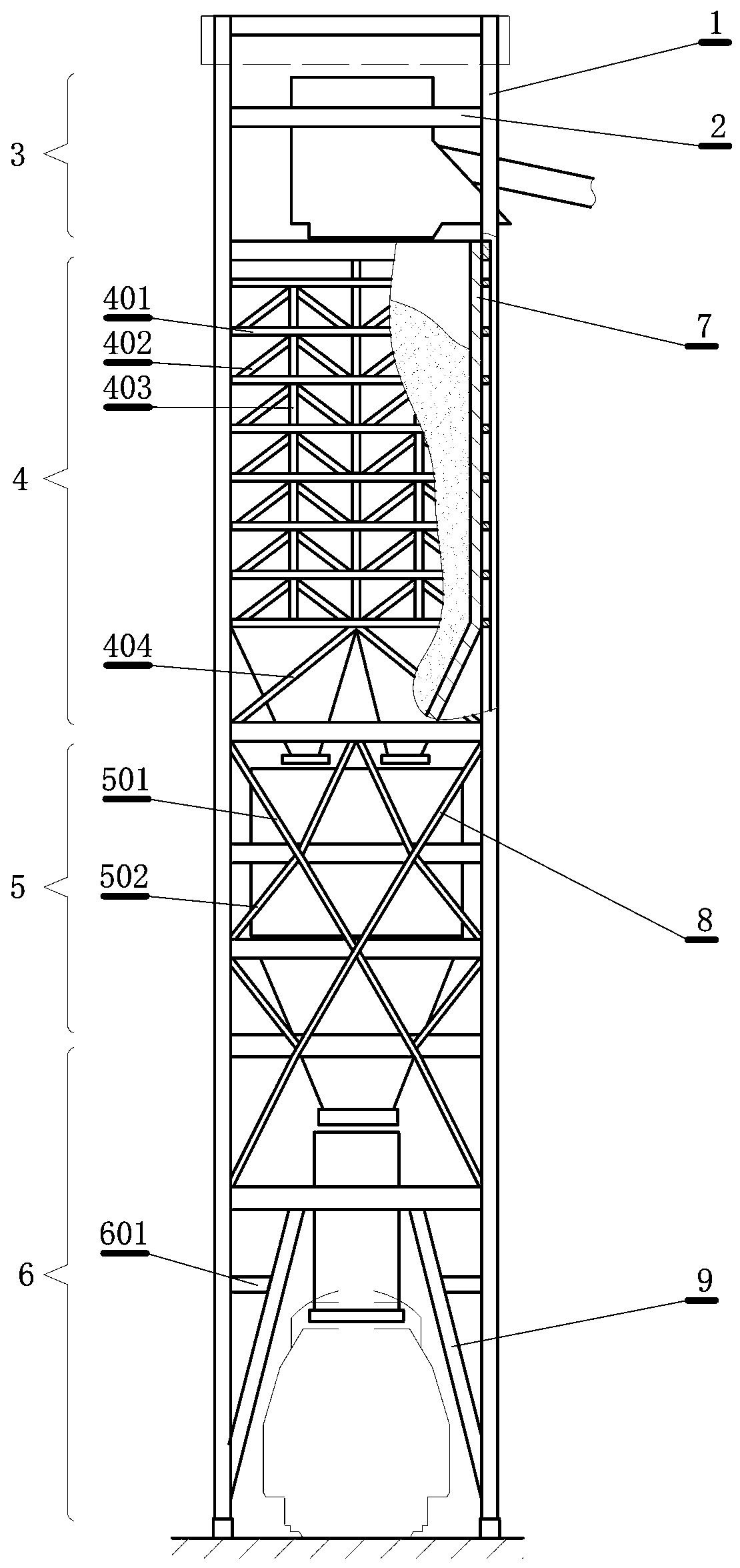

[0020] This embodiment is a steel structure frame of a loading station in which the warehouse body and the support structure are integrated, such as figure 1 shown. This embodiment includes: at least four vertical columns 1, and beams 2 connecting the columns are arranged between the columns. The columns and beams form a basic structure, and the basic structure is divided into Belt conveyor head layer 3, buffer bin layer 4, quantitative bin layer 5, chute and vehicle layer 6, the columns and beams of the buffer bin layer are connected to the side plates 7 of the buffer bin through densely arranged connectors or welding, A fork-shaped truss 8 is arranged on the quantitative warehouse layer, and a slanted pillar 9 is arranged on the chute and the vehicle layer.

[0021] The basic idea of this embodiment is to integrate the buffer warehouse with the largest load capacity (generally carrying nearly 100 tons or more of bulk cargo) with the rigid structure frame, and use the side...

Embodiment 2

[0043] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the buffer layer. At least two groups of herringbone inclined beams 402 are set up side by side between the buffer storey beams 401 described in this embodiment, and short columns 403 are arranged in the middle and both sides of the said herringbone inclined beams, such as figure 1 shown.

[0044] In order to maintain the stability of the buffer silo slab, set beams on the slab and use welding to connect them, or use connectors, that is, high-strength bolts to firmly connect each beam to the slab. Herringbone inclined beams are used between the beams, and small columns are arranged between the inclined beams. Through the herringbone inclined beam and the small column, the stress on the warehouse plate is transferred to the column, and at the same time, the instability of the plate surface caused by the lateral force is avoided.

Embodiment 3

[0046] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment regarding the buffer storey layer. The lowermost beam of the buffer warehouse layer described in this embodiment is provided with a large herringbone beam 404 connected to the column, such as figure 1 shown.

[0047] The center of the large herringbone inclined beam is supported at the center of the bottom beam of the buffer storey, that is, the position with the largest winding, to ensure the stability of the beams of each buffer store.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com