Volatile oil extraction and separation device and volatile oil extraction and separation system

A technology for separating equipment and volatile oil, applied in the directions of essential oils/spices, fat production, etc., can solve the problems of inability to industrialize application, low utilization rate of medicinal materials, small evaporation, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

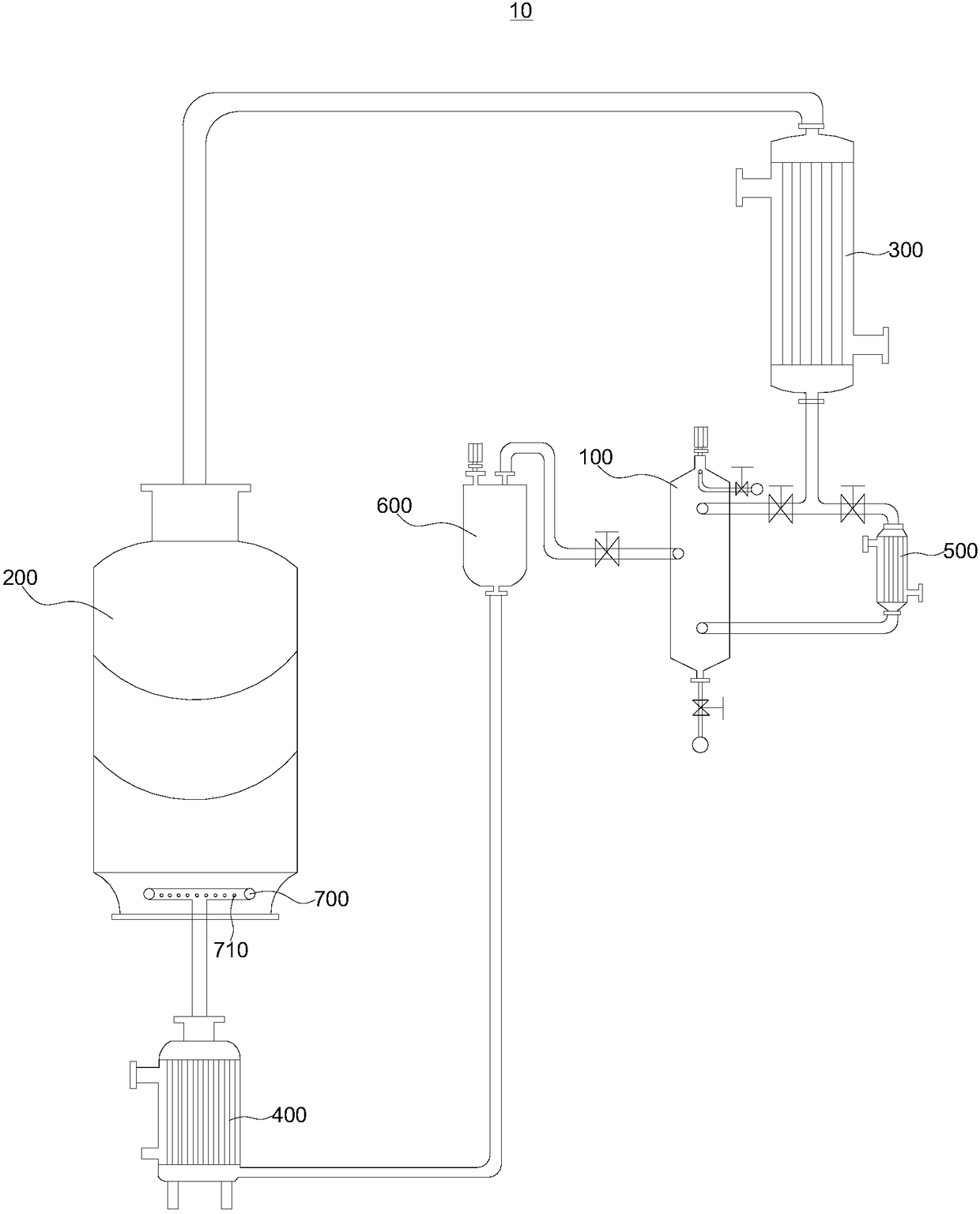

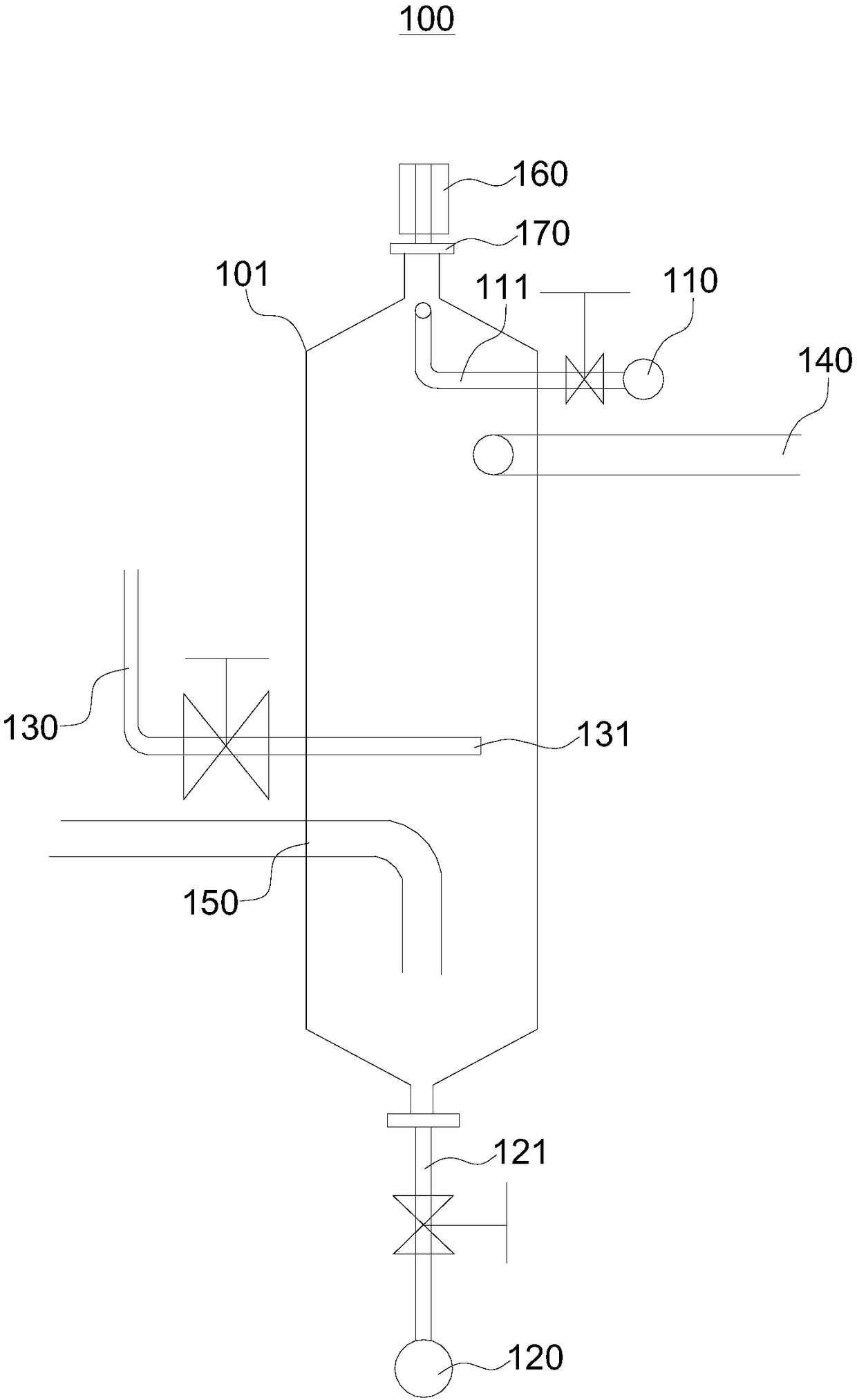

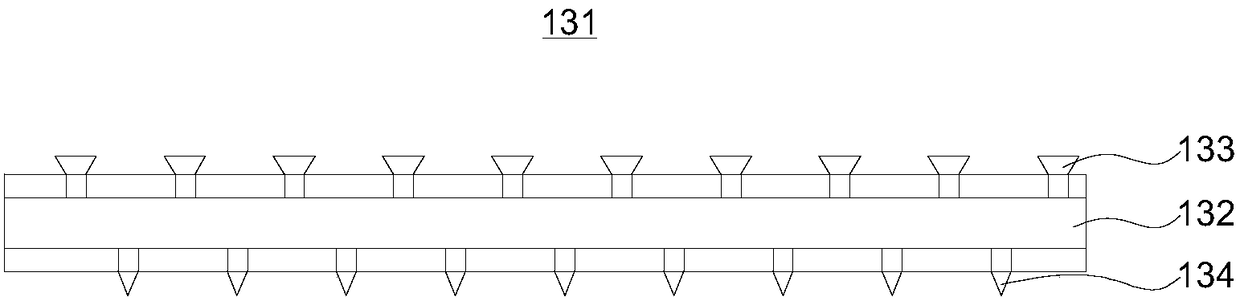

[0032] Please refer to figure 1 , the present embodiment provides a volatile oil extraction and separation device 10, which includes a bubbling oil-water separator 100, an extraction tank 200, a condenser 300, a steam generator 400, a cooler 500, a buffer tank 600 and a steam distributor 700.

[0033] The top of the extraction tank 200 is communicated with the condenser 300; the discharge end of the condenser 300 is communicated with the bubbling oil-water separator 100, the discharge end of the bubbling oil-water separator 100 is communicated with the steam generator 400, and the outlet of the steam generator 400 The material end communicates with the extraction tank 200; the cooler 500 is installed between the condenser 300 and the steam generator 400, the buffer tank 600 is connected between the bubbling oil-water separator 100 and the steam generator 400, and the steam uniform distributor 700 and the steam One end of the generator 400 away from the buffer tank 600 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com