Heat pipe heating and fluid heating composite type pavement snow melting system and operation control method thereof

A heating system and composite technology are applied in the field of airport pavement snow melting systems and their operation strategies, which can solve the problems of low snow removal efficiency, large pavement damage, and high energy consumption, and achieve environmentally friendly operation, reduce operating costs, and have no energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

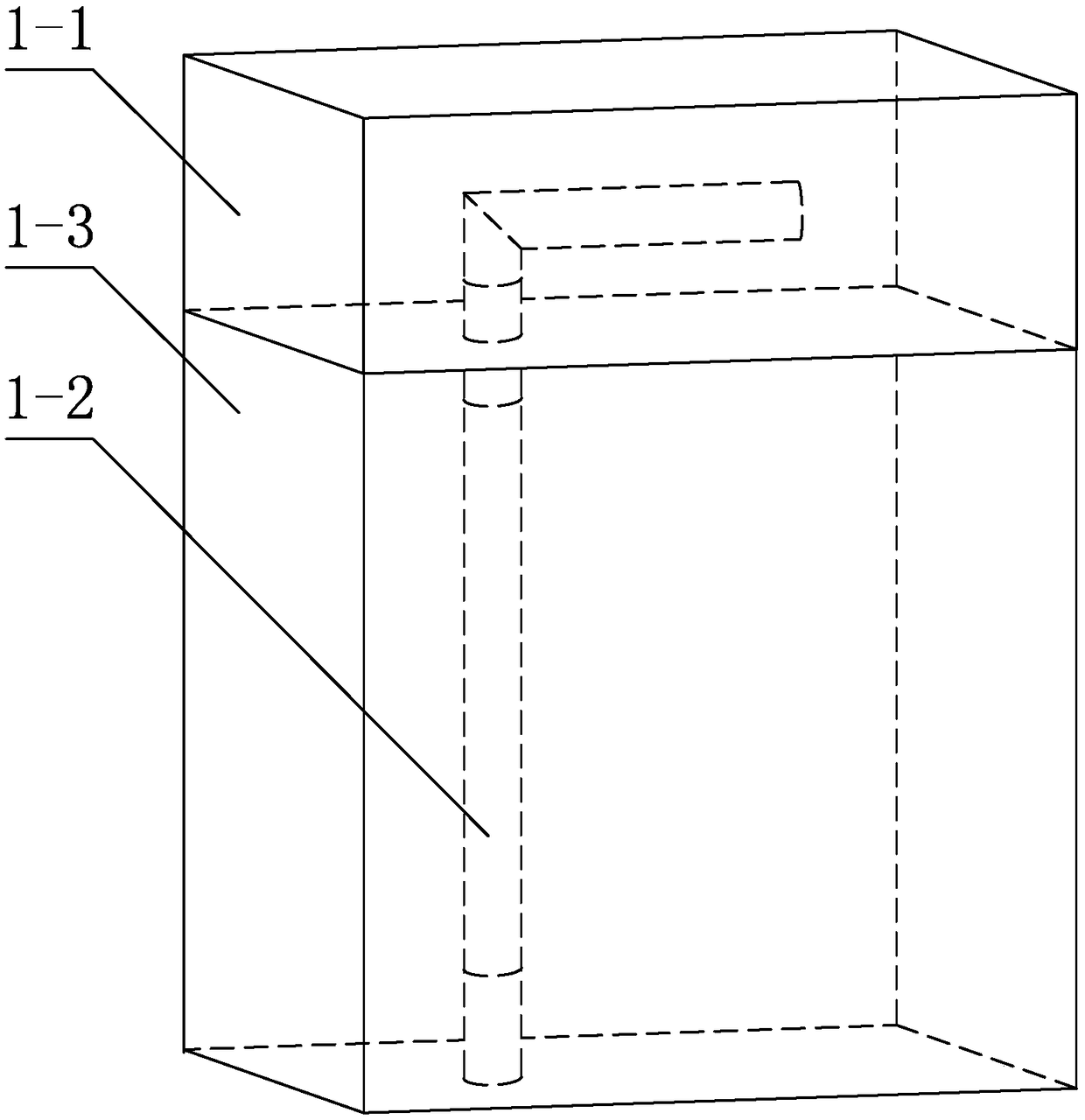

[0044] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment mode, a heat pipe heating and fluid heating composite pavement snow melting system of this embodiment, the snow melting system includes a pavement structure layer 1-1 and an underground soil layer 1-3, it also includes a heat pipe heating system and a fluid heating system Heating system;

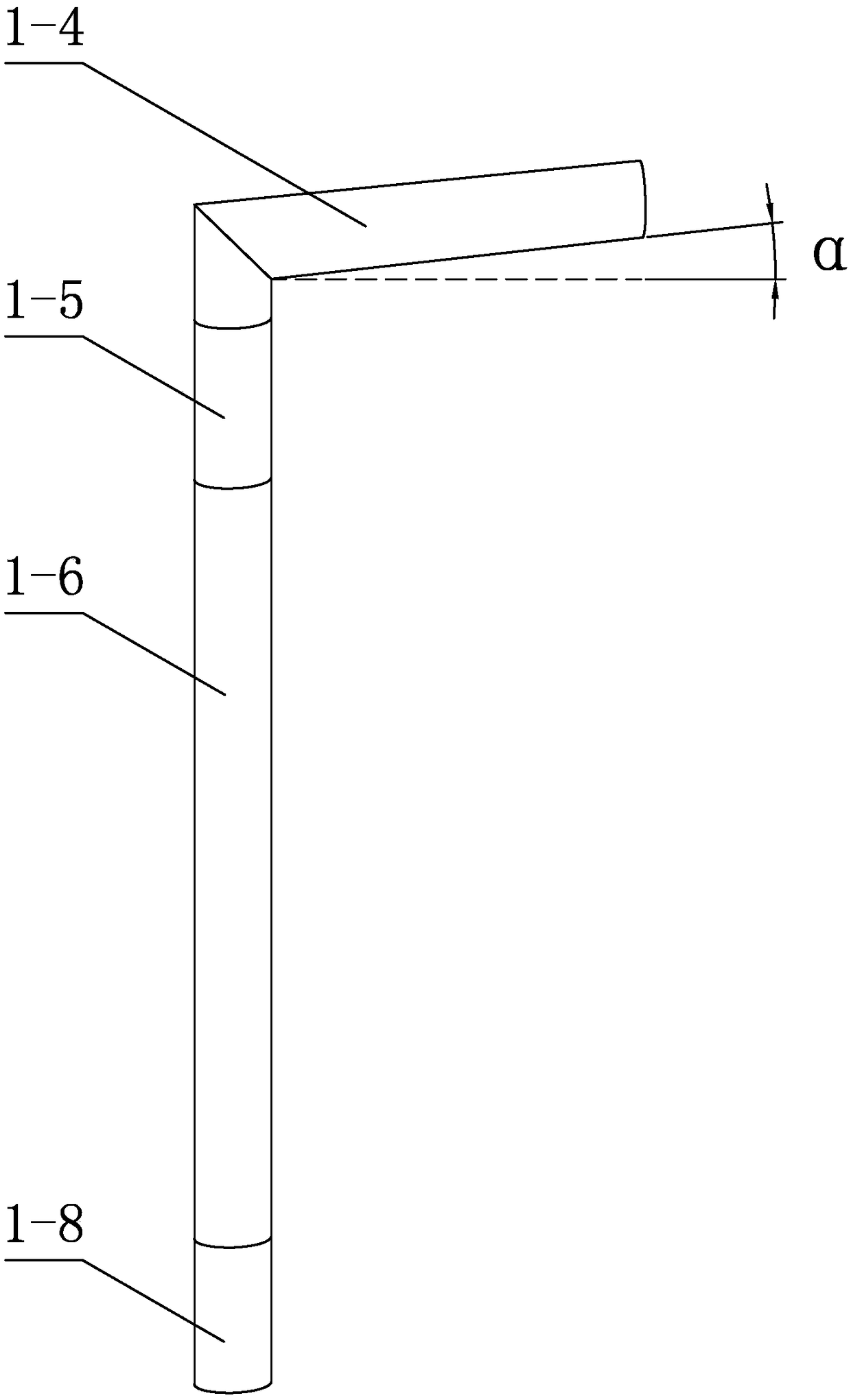

[0045] The heat pipe heating system includes multiple gravity heat pipes 1-2, which are arranged in parallel inside the pavement structure layer 1-1 and the underground soil layer 1-3, and each gravity heat pipe 1-2 includes condensation Sections 1-4, adiabatic section 1-5, evaporating section 1-6, and liquid storage tank 1-8, condensing section 1-4, adiabatic section 1-5, and evaporating section 1-6 are connected sequentially from top to bottom, condensing Section 1-4 is obliquely arranged inside the pavement structure layer 1-1, evaporation section 1-6 is vertically arranged inside the undergro...

specific Embodiment approach 2

[0050] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, the heat pump unit 2-2 of the fluid heating system in this embodiment includes an evaporator 2-8, a condenser 2-9, an air compressor 2-10, a third control valve 2-11, and a condenser outlet pipe and the condenser water inlet pipe, the first inlet port of the evaporator 2-8 is communicated with the water outlet pipe 2-5 of the heat extraction system, the first outlet end of the evaporator 2-8 is communicated with the water inlet pipe 2-4 of the heat extraction system, and the evaporator The second inlet port of 2-8 communicates with the first outlet port of condenser 2-9 through the condenser water outlet pipe, and an air compressor is arranged on the condenser water outlet pipe between evaporator 2-8 and condenser 2-9 2-10, the second outlet port of the evaporator 2-8 communicates with the first inlet port of the condenser 2-9 through the condenser water inlet pipe, and the condenser ...

specific Embodiment approach 3

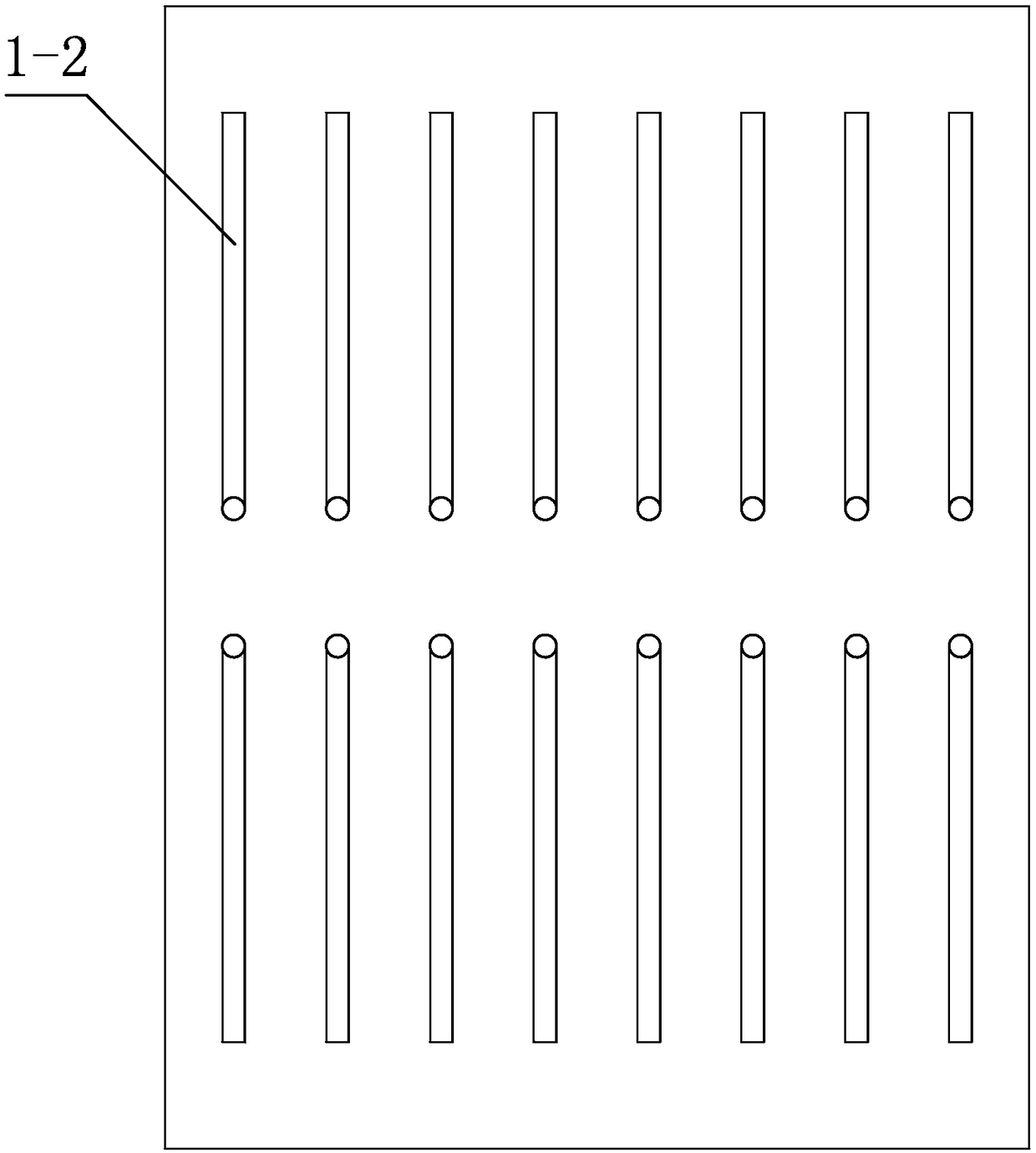

[0051] Specific implementation mode three: combination image 3 and Figure 5 To illustrate this embodiment, the road surface cooling pipes 2-3 of the fluid heating system of this embodiment are arranged inside the road surface structure layer 1-1 using S-shaped coils, and the multiple gravity heat pipes 1-2 of the heat pipe heating system are arranged on the The position between the heat pipes 2-3 on the road surface, the depth of the heat pipe 2-3 from the upper surface of the road structure layer 1-1 and the depth of the gravity heat pipe 1-2 from the upper surface of the road structure layer 1-1 are set in the same way, and the road surface The distance between the heat dissipation pipe 2-3 and the upper surface of the pavement structure layer 1-1 is 6-15cm in depth. The plurality of gravity heat pipes 1-2 exist independently. Due to the long surface size, in order to facilitate heat transfer, it is advisable to adopt the arrangement of double-row gravity heat pipes 1-2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com