Brake device suitable for bearing refractory brick kiln car

A braking device and refractory brick technology, which is applied in the field of braking devices, can solve the problems of low braking device strength, poor braking effect, and short service life, and achieve the effects of improving braking effect, prolonging service life, and improving quality and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

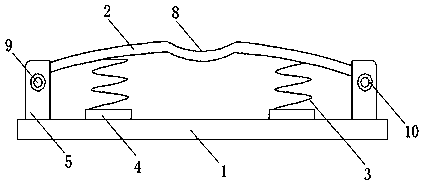

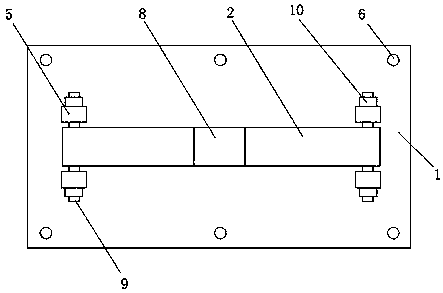

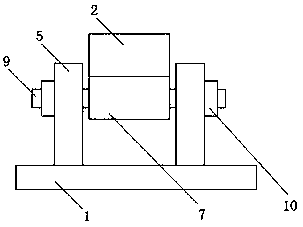

[0014] as attached Figure 1-3 Shown: a brake device suitable for carrying refractory brick kiln cars, including a mounting plate 1, a brake plate 2 and a spring 3, characterized in that: the mounting plate 1 is provided with cushion blocks 4, fixing blocks 5, and mounting holes 6. The mounting hole 6 facilitates the installation of the mounting plate 1, and can also improve the firmness of the mounting plate 1 after installation. The two ends of the brake plate 2 are provided with mounting blocks 7, and the brake plate 2 is provided with reinforcing grooves 8. The brake plate 2 is set in an arc-shaped structure, the reinforcing groove 8 is set in an arc-shaped structure, the brake plate 2 is set in an arc-shaped structure, and the brake plate 2 is provided with an arc-shaped reinforcing groove 8. The quality strength of the brake plate 2 is improved, and the braking effect of the kiln car is enhanced. The installation block 7 is provided with a connecting rod 9, and the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com