Air gun launching device with quick release mechanism

A technology of releasing mechanism and launching device, which is applied to compressed air guns, weapons without explosives, offensive equipment, etc., can solve the problems of launching speed error, large consumption, and potential safety hazards, so as to reduce energy consumption and improve launching accuracy. , the effect of high launch speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

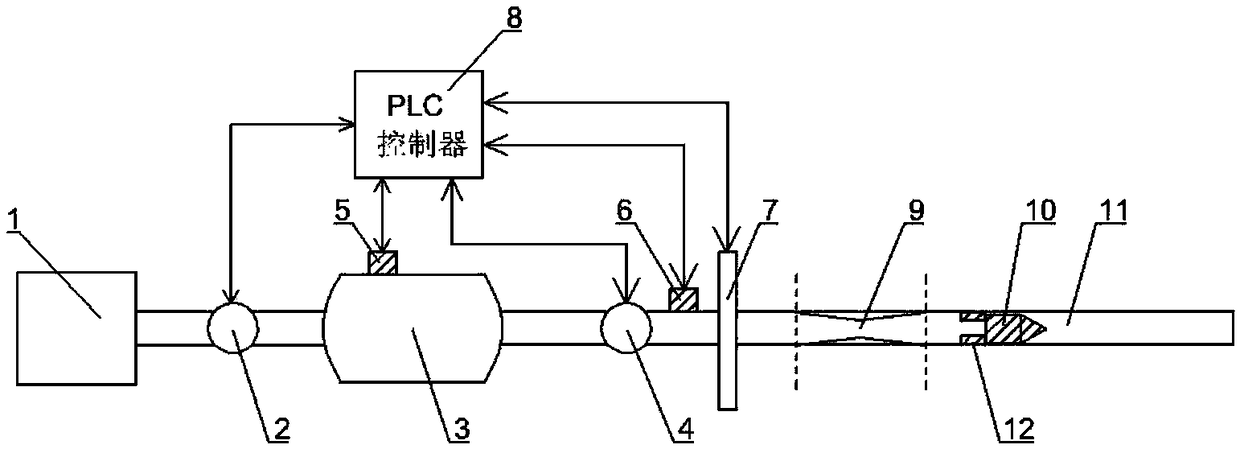

Embodiment 1

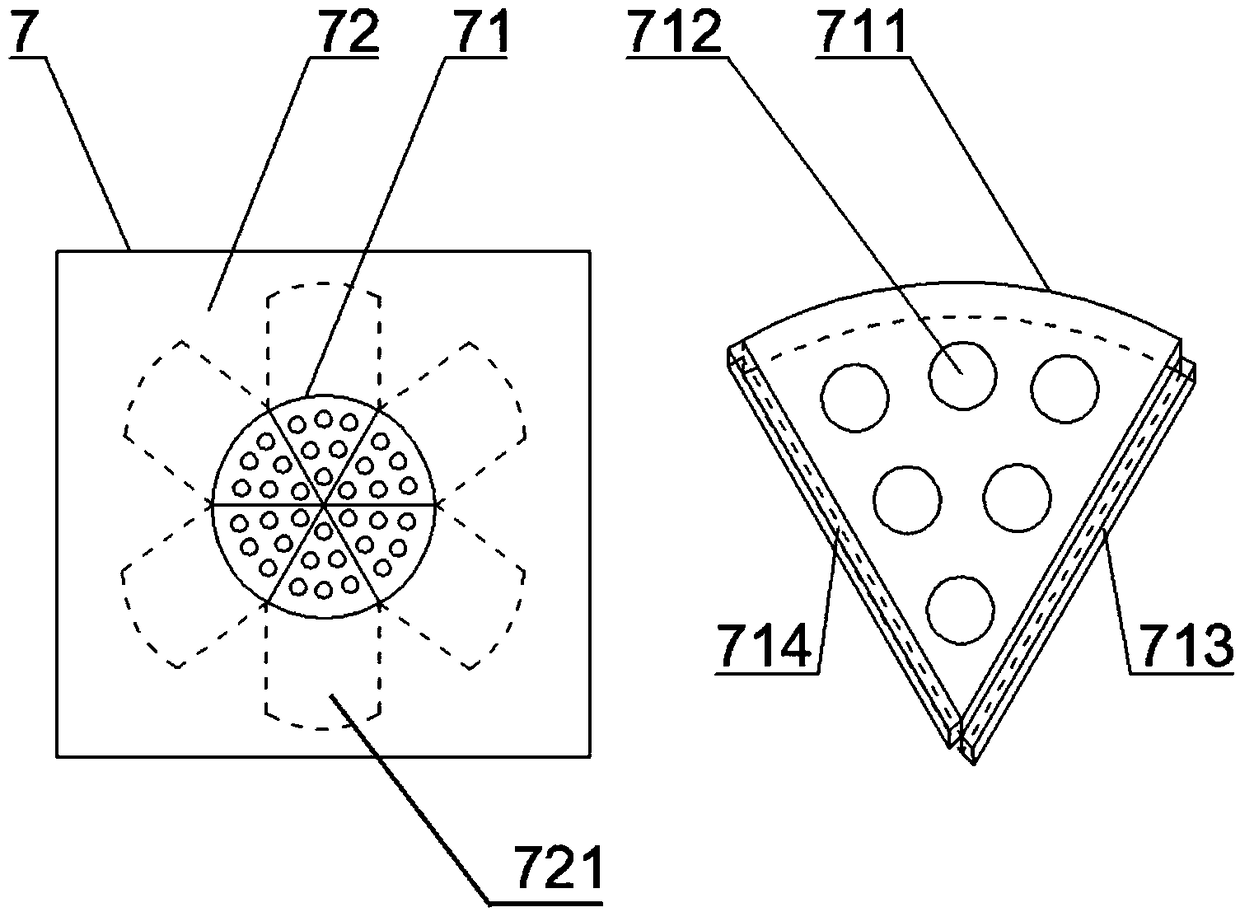

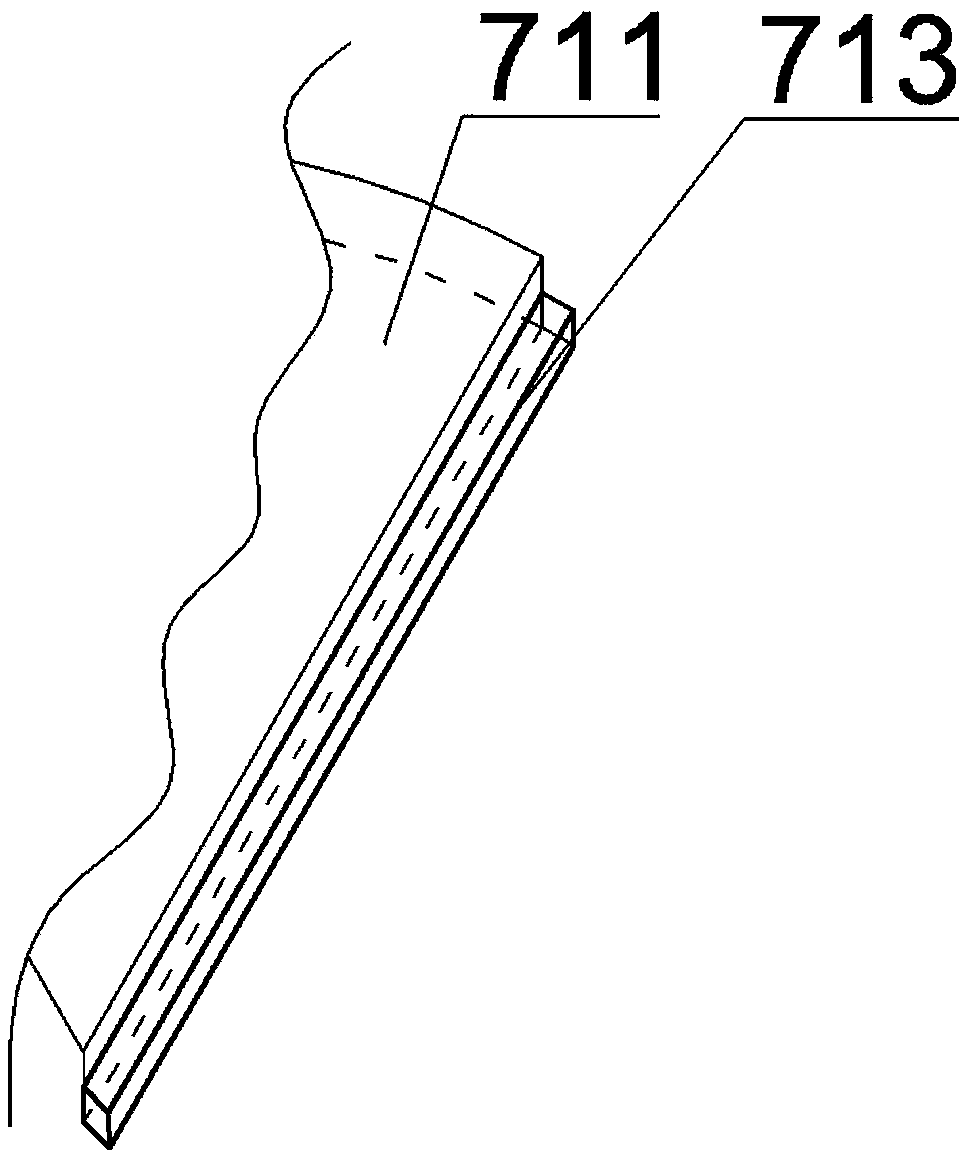

[0024] The quick-release mechanism 7 is a fan-shaped telescopic quick-release mechanism with openable and closable round holes. It consists of six equal fan-shaped structures 711 meshed into a well-closed cylinder 71. The fan-shaped structures 711 are telescopic. When going out, the upper and lower engaging mechanisms 714, 713 engage with adjacent mechanisms to close the gas passage, and when contracting, they retreat into the cuboid shell 72 to quickly open the gas passage. Each fan-shaped structure 711 also has six openable and closable small cylindrical structures 712, the working principle of which is the same as that of the fan-shaped structure 711, which can be stretched in and out of the fan-shaped structure 711, thereby controlling the flow of gas. In order to allow the fan-shaped structure 711 to freely expand and contract into the cuboid shell 72, there is a height difference between the upper and lower surfaces of the cylinder 71 formed by the meshing of the fan-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com