A magnetic fluid liquid cooling plate, a liquid cooling system composed of the same, and a control method thereof

A liquid-cooling plate, magnetic fluid technology, applied in electrical components, electrochemical generators, secondary batteries, etc., can solve the problems of abnormal rise in module temperature, high temperature, and inability to accurately and effectively reduce module temperature, etc. Achieve the effect of improving service life and performance, and improving the consistency of temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

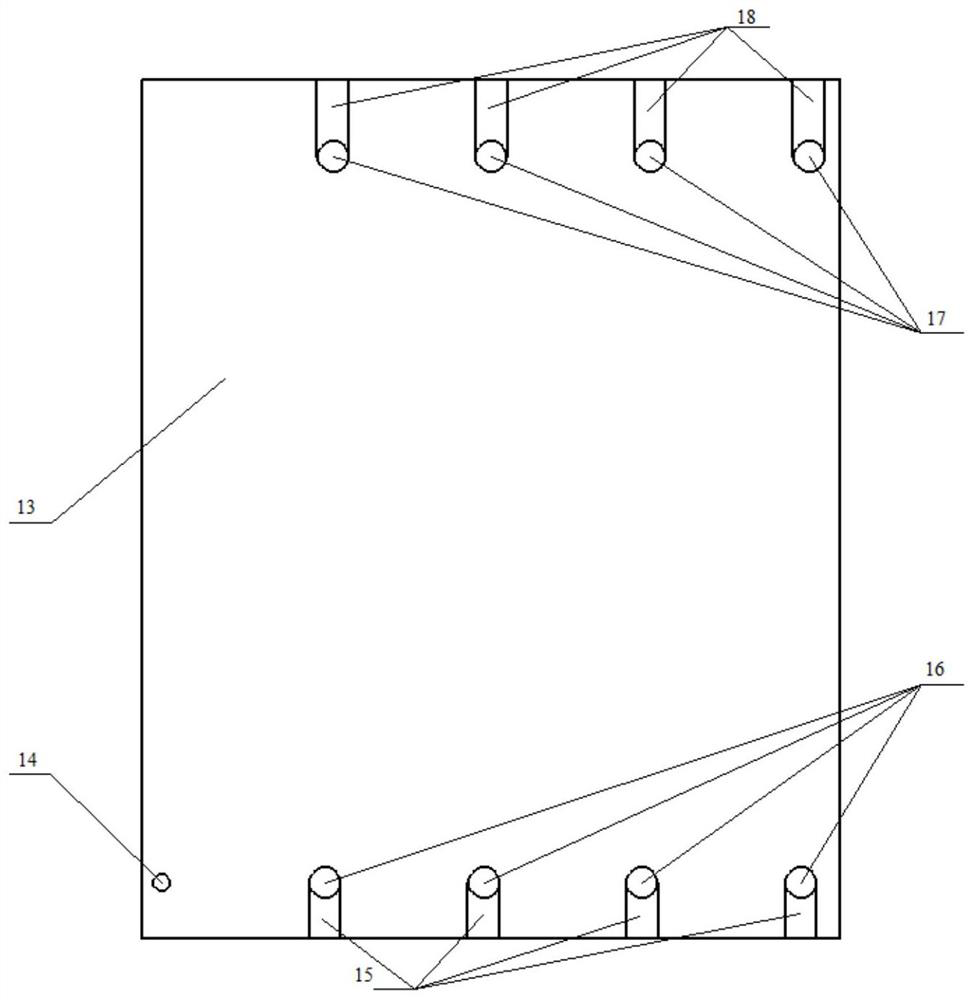

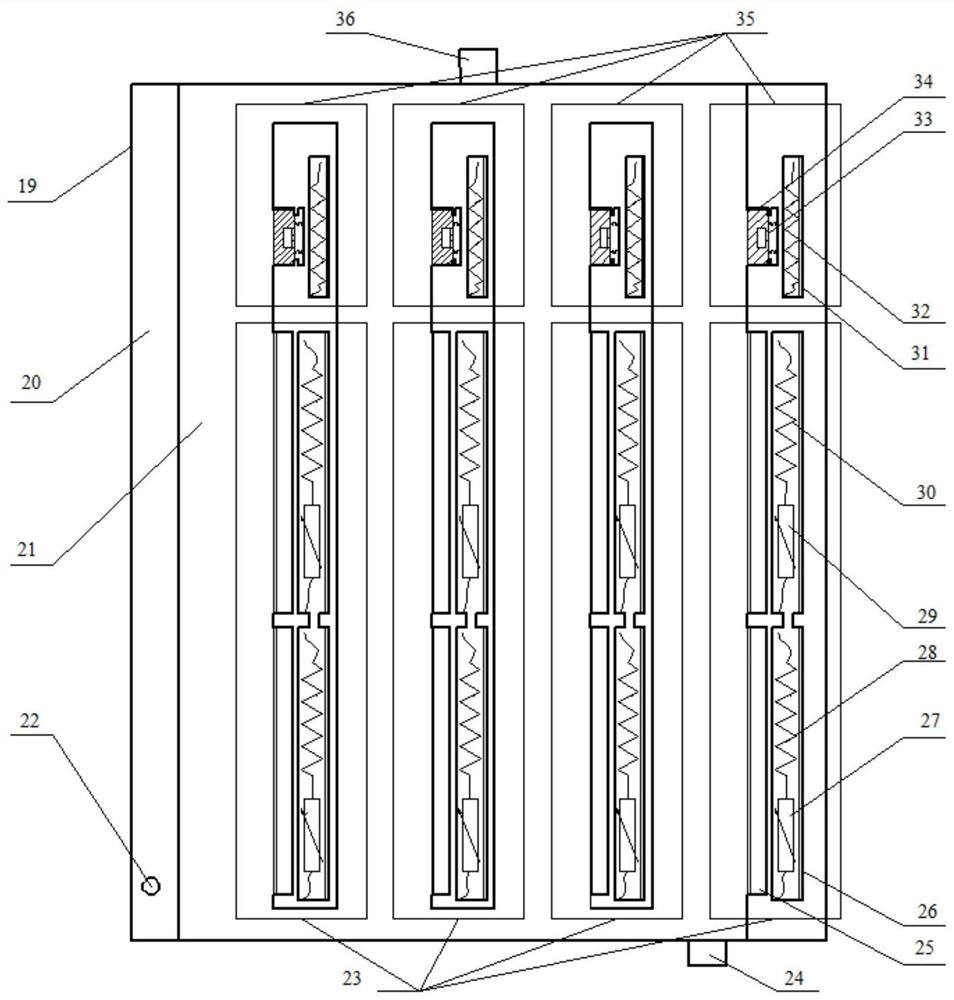

[0027] The structure and working principle of a liquid cooling device based on a variable magnetic fluid channel of the present invention will be further described below in conjunction with the accompanying drawings.

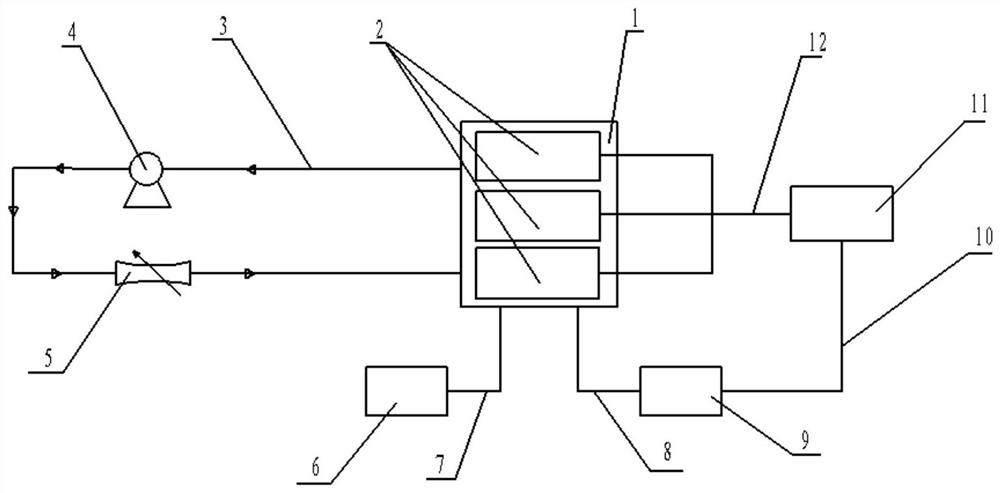

[0028] Such as figure 1 As shown, a liquid cooling system based on a variable magnetic fluid flow channel in the present invention includes a battery module subsystem, a coolant circulation subsystem and a flow channel control subsystem. The battery module subsystem includes a battery module 2 and a BMS11, the temperature information collection line 12 transmits battery temperature information, the coolant circulation subsystem includes a liquid cooling plate 1, a water pump 4 and a discharge valve 5, which are connected through a liquid cooling pipeline 3, and the flow channel control subsystem includes an external power supply 6. The magnetic fluid controller 9 and the liquid cold plate 1 are connected inside the subsystem through the power line 7 and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com