Semiautomatic apple picking machine

A semi-automatic, harvesting machine technology, applied in the direction of picking machines, harvesters, agricultural machinery and tools, etc., can solve the problems of low picking efficiency, high labor intensity of fruit farmers, and lack of picking work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

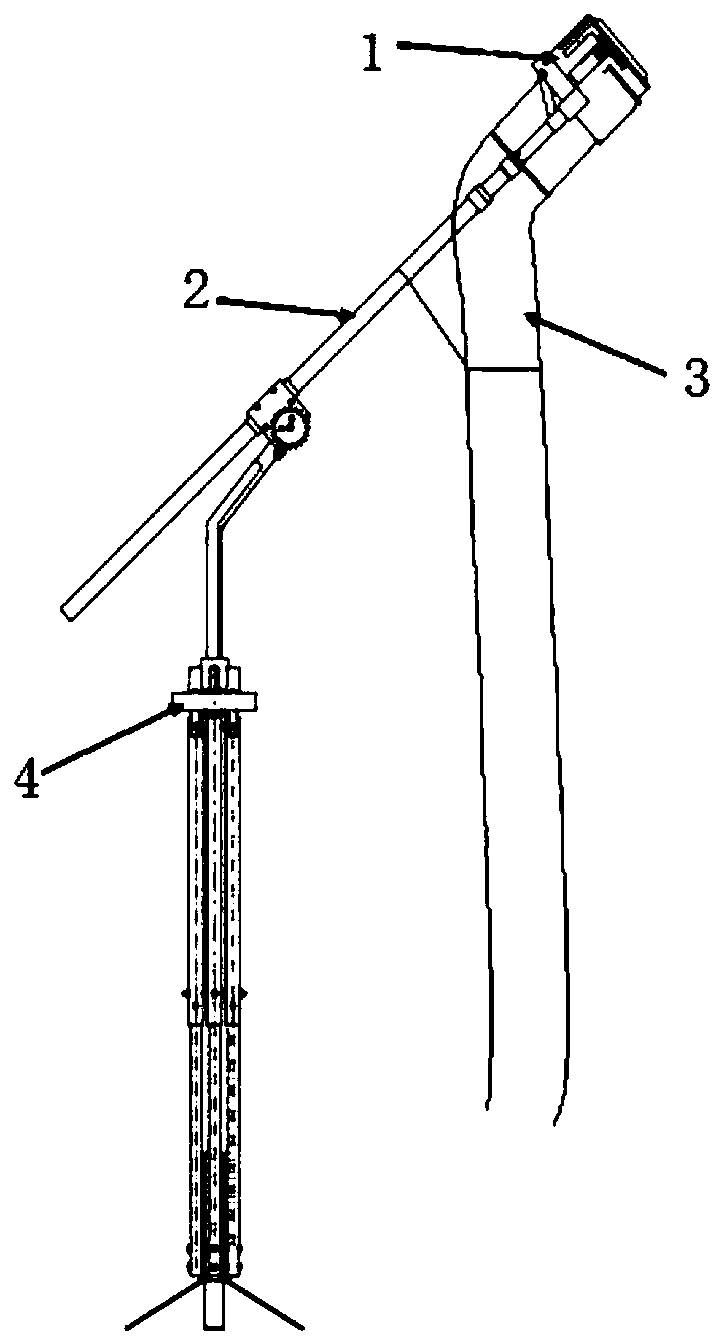

[0022] refer to figure 1 As shown, a small semi-automatic apple picker includes a picker head and a motor control part 1, a single-axis retractable operating rod part 2, a collection part 3, and a bottom bracket part 4.

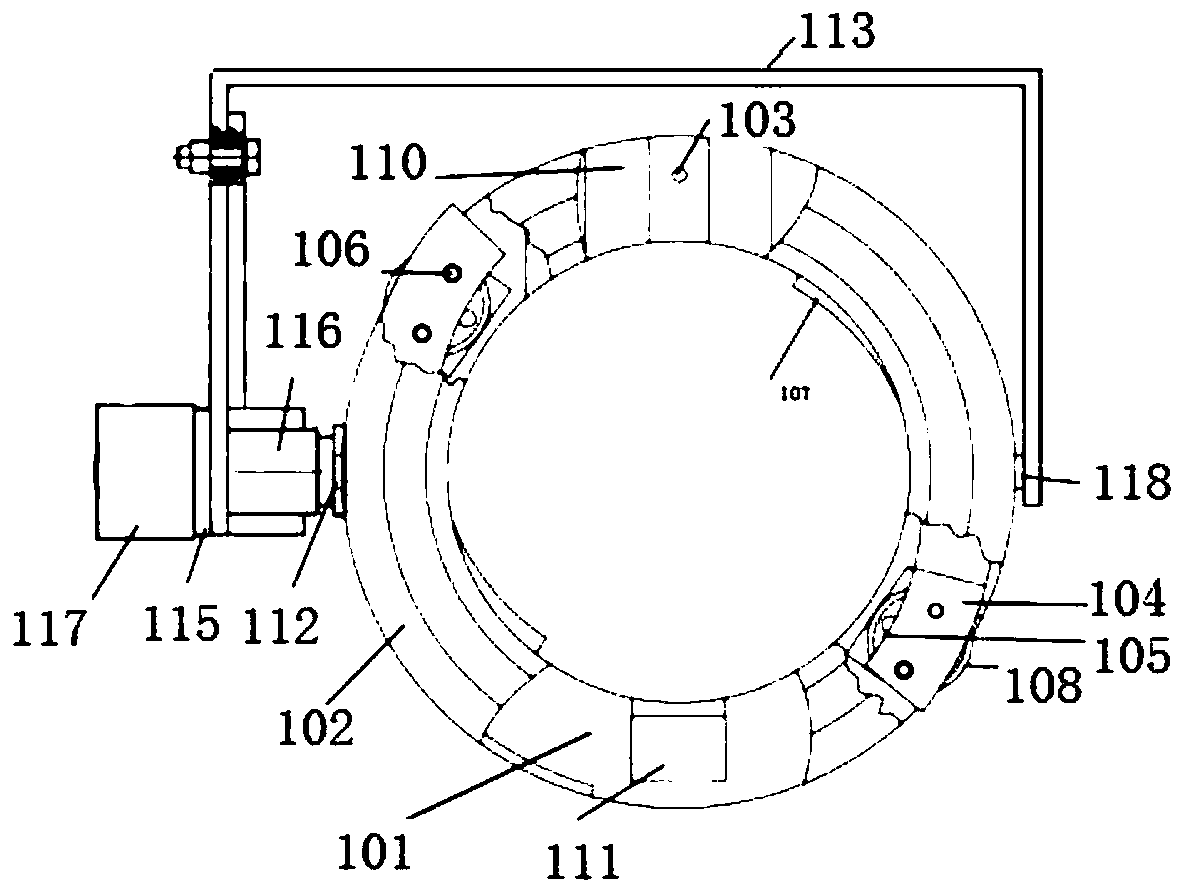

[0023] like figure 2 As shown, the picking machine head and the motor control part 1 include a cylinder body 101, the top of the cylinder body 101 is fixed with a separation cover 102 by fastening screws 103, and a reduction motor 108 is arranged in the motor slot at the top of the cylinder body 101, and the reduction motor 108 fixes the arc-shaped dislocation tool holder 104 through the flange 105 and the bolt 106, and fixes the arc-shaped blade 107 on the arc-shaped dislocation tool holder 104; The lower end of the cylinder body 101 is connected to the collection part 3 . One side of the cylinder body 101 is provided with a square through hole, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com