A method for preparing tantalum biocoating by magnetron sputtering on the surface of magnesium alloy

A magnetron sputtering, bio-coating technology, applied in metal material coating process, coating, sputtering and other directions, can solve the problem of unsatisfactory biocompatibility, poor corrosion resistance, loss of mechanical properties, etc. problem, to achieve good bone-inducing activity, good coating adhesion, and good bone conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

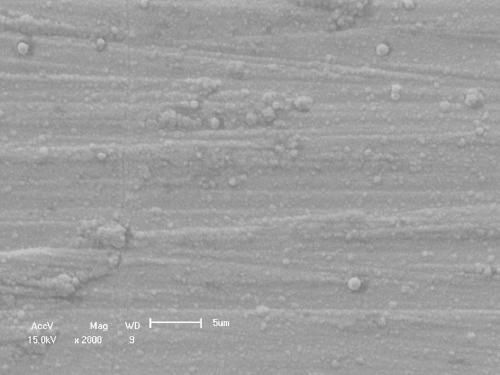

[0050] Preparation of tantalum biocoating on magnesium alloy surface by magnetron sputtering.

[0051] Such as Figure 5 Shown in the process flow chart, the present embodiment carries out according to the following steps:

[0052] 1. Sample grinding and cleaning: the sample is polished with 200#-2000# sandpaper, washed in cold water, degreased with acetone, ultrasonically cleaned with ethanol, and then dried for use;

[0053] 2. Installation: Install the sample, aluminum (Al) target, and tantalum (Ta) target into the magnetron sputtering chamber, ensuring that the distance between the sample surface and the target is 8cm;

[0054]3. Vacuumize and fill with argon: vacuumize the magnetron sputtering chamber to ≤1×10 -3 Pa, filled with argon to 0.4Pa;

[0055] 4. Preparation of aluminum (Al) transition layer by magnetron sputtering:

[0056] 4a. Select an aluminum (Al) target;

[0057] 4b. Adjust the voltage to 265V, and magnetron sputtering for 5 minutes;

[0058] 4c. Tur...

Embodiment 2

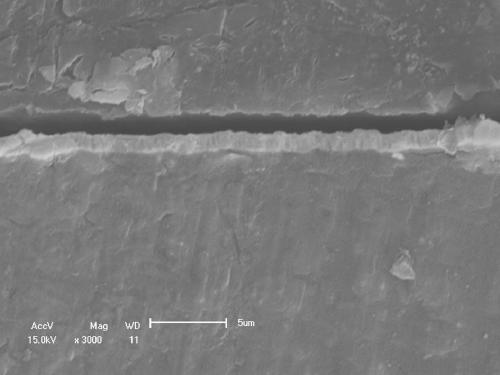

[0067] Preparation of tantalum biocoating on magnesium alloy surface by magnetron sputtering.

[0068] Such as Figure 5 Shown in the process flow chart, the present embodiment carries out according to the following steps:

[0069] 1. Sample grinding and cleaning: the sample is polished with 200#-2000# sandpaper, washed in cold water, degreased with acetone, ultrasonically cleaned with ethanol, and then dried for use;

[0070] 2. Installation: Install the sample, aluminum (Al) target, and tantalum (Ta) target into the magnetron sputtering chamber, ensuring that the distance between the sample surface and the target is 9cm;

[0071] 3. Vacuumize and fill with argon: vacuumize the magnetron sputtering chamber to ≤1×10 -3 Pa, filled with argon to 0.4Pa;

[0072] 4. Preparation of aluminum (Al) transition layer by magnetron sputtering:

[0073] 4a. Select an aluminum (Al) target;

[0074] 4b. Adjust the voltage to 270V, and magnetron sputtering for 7 minutes;

[0075] 4c. Tu...

Embodiment 3

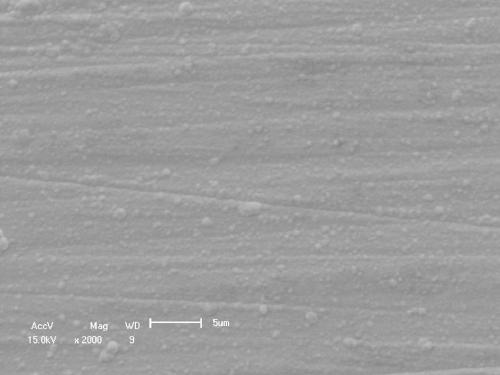

[0083] Preparation of tantalum biocoating on magnesium alloy surface by magnetron sputtering.

[0084] Such as Figure 5 Shown in the process flow chart, the present embodiment carries out according to the following steps:

[0085] 1. Sample grinding and cleaning: the sample is polished with 200#-2000# sandpaper, washed in cold water, degreased with acetone, ultrasonically cleaned with ethanol, and then dried for use;

[0086] 2. Installation: Install the sample, aluminum (Al) target, and tantalum (Ta) target into the magnetron sputtering chamber, ensuring that the distance between the sample surface and the target is 10cm;

[0087] 3. Vacuumize and fill with argon: vacuumize the magnetron sputtering chamber to ≤1×10 -3 Pa, filled with argon to 0.4Pa;

[0088] 4. Preparation of aluminum (Al) transition layer by magnetron sputtering:

[0089] 4a. Select an aluminum (Al) target;

[0090] 4b. Adjust the voltage to 275V, and magnetron sputtering for 8 minutes;

[0091] 4c. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com