Solution formula and process of preparing tantalum-containing coating on magnesium and magnesium alloy surface by micro-arc oxidation

A micro-arc oxidation and magnesium alloy technology, applied in the direction of surface reaction electrolytic coating, coating, anodic oxidation, etc., can solve the problems of loss of mechanical properties, unsatisfactory biocompatibility, poor corrosion resistance, etc., and achieve good Effects of osteoconductivity, good osteoinductive activity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

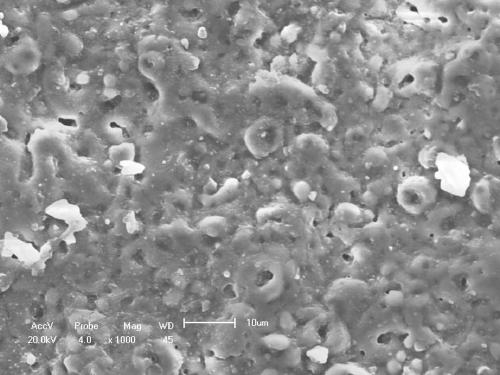

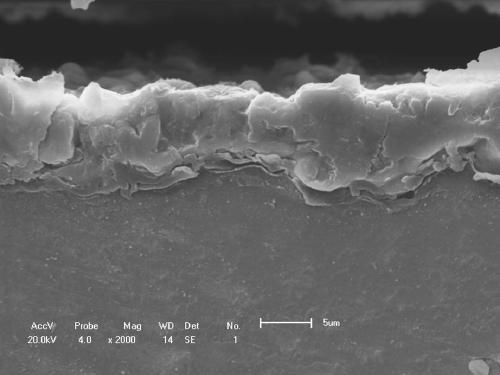

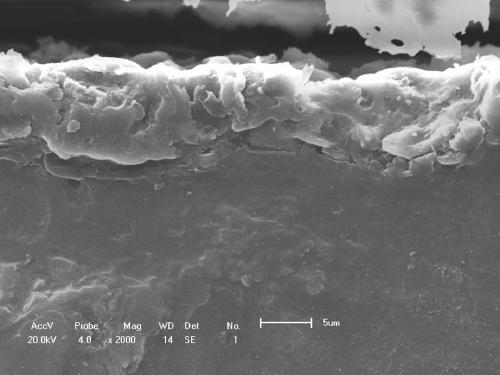

[0044] The tantalum-containing coatings on the surface of magnesium and magnesium alloys were prepared by micro-arc oxidation.

[0045] Such as Figure 5 As shown in the process flow chart, this embodiment is carried out according to the following steps: 1. After polishing the magnesium-aluminum alloy sample with 200#, 600#, 1200# and 1500# sandpaper, it is washed in cold water, soaked in acetone for 5 minutes to remove oil, and anhydrous Ultrasonic cleaning with ethanol for 5 minutes, then blow dry for use; 2. Prepare micro-arc oxidation solution: containing 8g / L sodium silicate, 6g / L trisodium phosphate, 1g / L sodium hydroxide, 5ml / L ethanol For tantalum, the solvent is distilled water, and the prepared solution is stirred evenly with a glass rod; 3. Connect the sample to the anode of the micro-arc oxidation equipment, use a stainless steel sheet as the cathode, and adopt a large cathode and small anode structure (cathode area: anode area ≥ 2 ︰1); 4. Put the connected cathod...

Embodiment 2

[0049]The tantalum-containing coatings on the surface of magnesium and magnesium alloys were prepared by micro-arc oxidation.

[0050] Such as Figure 5 As shown in the process flow chart, this embodiment is carried out according to the following steps: 1. The magnesium alloy sample is washed in cold water after being polished by 200#, 600#, 1200# and 1500# sandpaper successively, soaked in acetone for 5min to remove oil, and degreased in absolute ethanol Ultrasonic cleaning for 10 minutes, then blow dry for use; 2. Prepare micro-arc oxidation solution: 9g / L sodium silicate, 7g / L trisodium phosphate, 1.5g / L sodium hydroxide, 7.5ml / L tantalum ethoxide , the solvent is distilled water, and the prepared solution is stirred evenly with a glass rod; 3. Connect the sample to the anode of the micro-arc oxidation equipment, use a stainless steel sheet as the cathode, and adopt a large cathode and small anode structure (cathode area: anode area ≥ 2: 1); 4. Put the connected cathode an...

Embodiment 3

[0053] The tantalum-containing coatings on the surface of magnesium and magnesium alloys were prepared by micro-arc oxidation.

[0054] Such as Figure 5 As shown in the process flow chart, this embodiment is carried out according to the following steps: 1. The magnesium alloy sample is washed in cold water after being polished by 200#, 600#, 1200# and 1500# sandpaper successively, soaked in acetone for 5min to remove oil, and degreased in absolute ethanol Ultrasonic cleaning for 10 minutes, then blow dry for use; 2. Prepare micro-arc oxidation solution: 10g / L sodium silicate, 8g / L trisodium phosphate, 2g / L sodium hydroxide, 10ml / L tantalum ethoxide, solvent It is distilled water, and the prepared solution is stirred evenly with a glass rod; 3. Connect the sample to the anode of the micro-arc oxidation equipment, use a stainless steel sheet as the cathode, and adopt a large cathode and small anode structure (cathode area: anode area ≥ 2: 1) ; 4. Put the connected cathode and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com