Zirconium alloy pipe surface treatment method and device

A surface treatment, zirconium alloy technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as high melting point of chromium, decline in mechanical properties of zirconium alloy, corrosion, etc., to improve corrosion resistance, The effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The zirconium alloy pipe surface treatment method provided in this embodiment comprises the following steps:

[0037] Magnetron sputtering coating step: using magnetron sputtering to plate chromium on the surface of the zirconium alloy pipe 3 to form a chromium film with a preset thickness;

[0038] Laser melting step: performing laser melting treatment on the chromium film.

[0039] Using the magnetron sputtering method, the chromium is combined with the surface of the zirconium alloy pipe 3 in a high-strength manner, and at the same time, the chromium film has a certain degree of compactness. Melting and high-speed cooling further improve the compactness of the chromium film and prevent its corrosion resistance from being affected by a small amount of pores. Combining the magnetron sputtering coating method with the laser melting technology, a dense corrosion-resistant chromium layer is formed on the surface of the zirconium alloy pipe 3, which greatly improves the c...

Embodiment 2

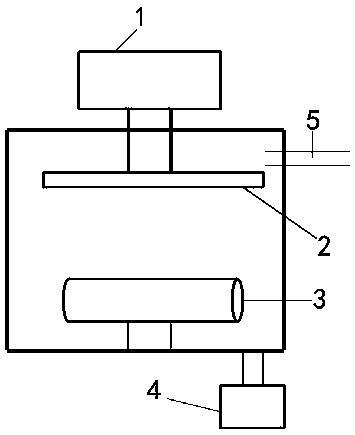

[0046] The zirconium alloy pipe surface treatment device provided in this embodiment, such as Figure 1 to Figure 2 As shown, it includes a magnetron sputtering coating device, a laser melting device, a vacuum device 4 and an inert gas filling device 5;

[0047] The magnetron sputtering coating device includes a cavity, and the vacuum device 4 and the inert gas filling device 5 are respectively communicated with the cavity;

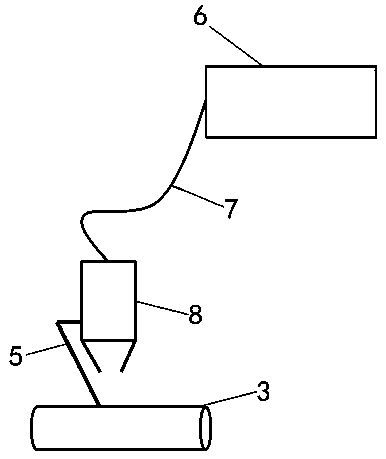

[0048] The laser melting device includes a laser processing head 8 , and the inert gas filling device 5 is also used for filling inert gas into the pipe processed by the laser processing head 8 .

[0049] Wherein, the zirconium alloy pipe material 3 is arranged in the cavity, and the magnetron sputtering coating device can coat the surface of the zirconium alloy pipe material 3 .

[0050] The laser processing head 8 can remelt and cool the coating film on the surface of the zirconium alloy pipe 3 at a high speed, and the inert gas filling device 5 can fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com