Graphene compound antirust agent and preparation method thereof

A technology of graphene and composites, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor corrosion resistance, achieve good anti-corrosion, solve poor corrosion resistance, and improve anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

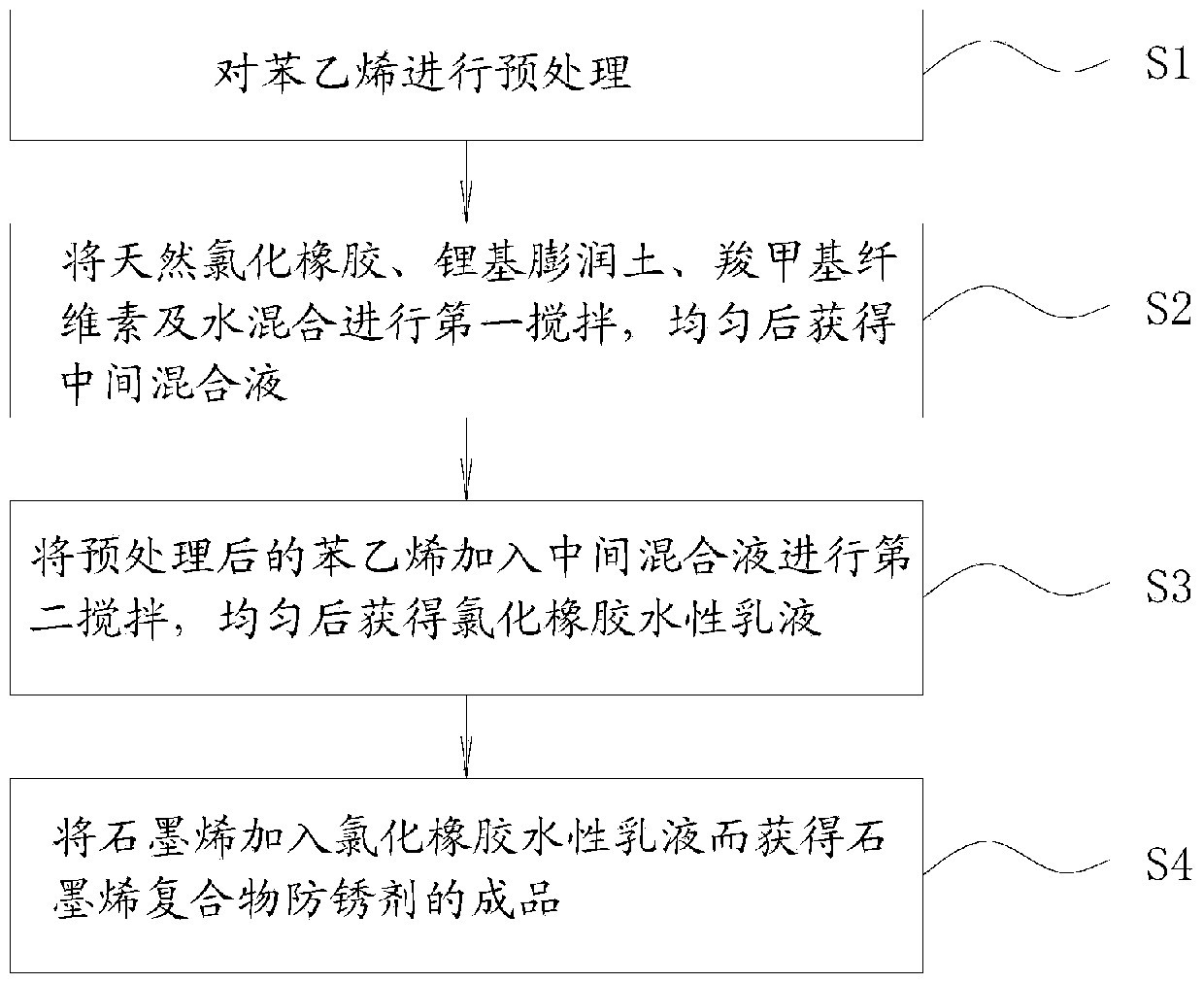

[0028] Based on the same invention, the application also provides a preparation method of a graphene composite antirust agent, see attached figure 1 , including the following steps:

[0029] S1: Pretreatment of styrene;

[0030] S2: Mix natural chlorinated rubber, lithium-based bentonite, carboxymethyl cellulose and water for the first stirring, and obtain an intermediate mixture after uniformity;

[0031] S3: Add the pretreated styrene to the intermediate mixture for the second stirring, and obtain a chlorinated rubber aqueous emulsion after being uniform;

[0032] S4: adding graphene to the aqueous emulsion of chlorinated rubber to obtain the finished product of the graphene composite antirust agent.

[0033] Further, the pretreatment of styrene in step S1 is as follows: the styrene is washed with alkali for 3 to 5 times by NaOH solution with a mass fraction of 5%; after the alkali washing is completed, the styrene is washed with water for 3 to 5 times until neutral .

...

Embodiment 1

[0037] S1: Wash the styrene four times with NaOH solution with a mass fraction of 5%; after the alkali washing is completed, wash the styrene four times with water until neutral;

[0038] S2: Mix 9% natural chlorinated rubber, 2.6% lithium-based bentonite, 2.2% carboxymethyl cellulose and 65.2% water for the first stirring, control the speed at 800r / min, and control the time at 15min, and obtain intermediate mixing after uniformity liquid;

[0039] S3: Add the pretreated 21% styrene to the intermediate mixture for the second stirring, control the rotation speed to 800r / min, and control the time to 18min to obtain a chlorinated rubber aqueous emulsion;

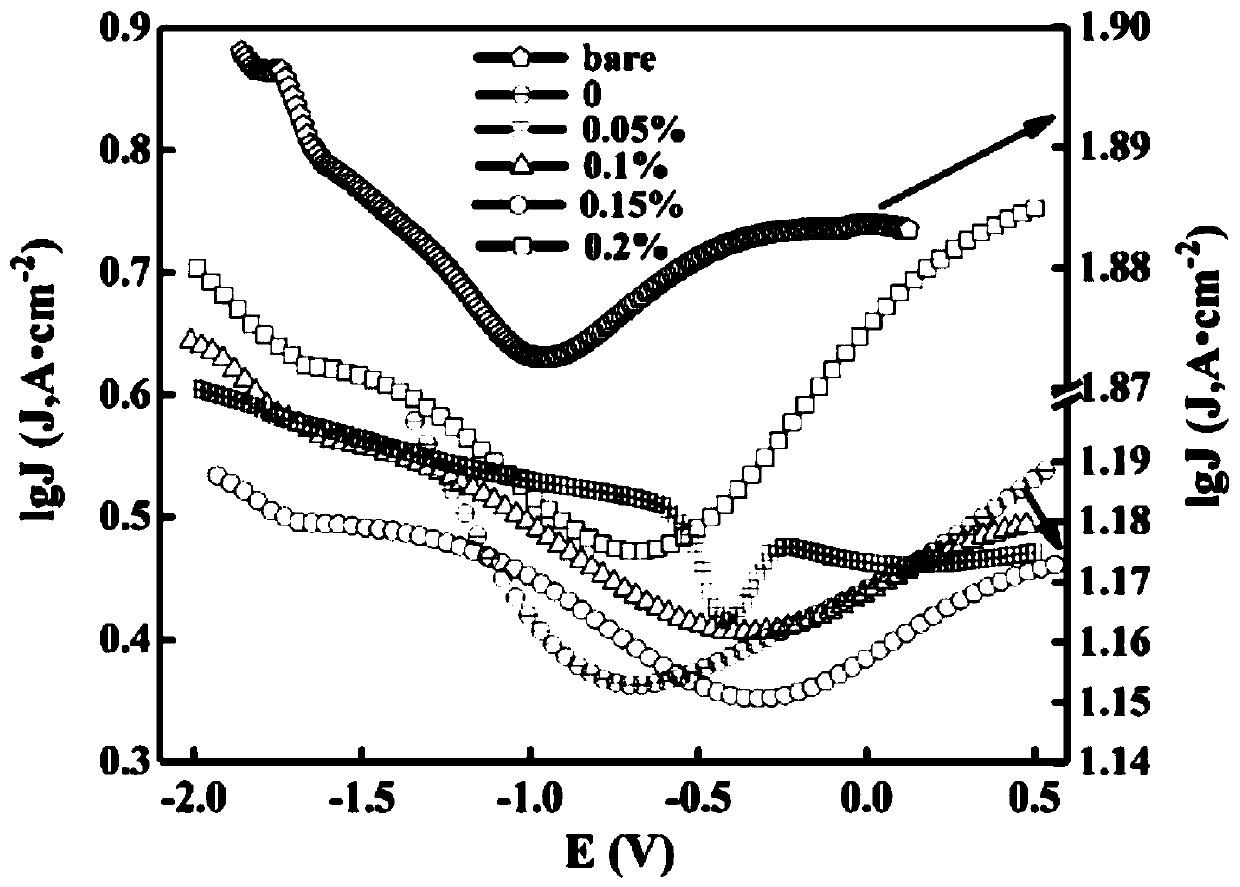

[0040] S4: Adding 0.05% graphene by mass to the aqueous emulsion of chlorinated rubber to obtain a finished graphene composite antirust agent.

Embodiment 2

[0042] S1: Wash the styrene four times with NaOH solution with a mass fraction of 5%; after the alkali washing is completed, wash the styrene four times with water until neutral;

[0043] S2: Mix 11% natural chlorinated rubber, 3% lithium-based bentonite, 2.8% carboxymethyl cellulose and 63.2% water for the first stirring, control the speed at 800r / min, and control the time at 15min, and obtain intermediate mixing after uniformity liquid;

[0044] S3: Add the pretreated 20% styrene to the intermediate mixture for the second stirring, control the rotation speed to 800r / min, and control the time to 18min to obtain a chlorinated rubber aqueous emulsion;

[0045] S4: Adding 0.1% graphene by mass to the aqueous emulsion of chlorinated rubber to obtain a finished graphene composite antirust agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com