A central heating system for combined heating of solar energy and low-grade industrial waste heat

An industrial waste heat and central heating technology, applied in hot water central heating system, heating system, energy industry, etc., can solve the problems of unstable heating load, low-grade industrial waste heat utilization efficiency and low proportion of clean energy heating, and achieve Achieve comprehensive utilization efficiency, solve the problem of waste heat utilization, and increase the effect of pipeline network transmission and distribution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

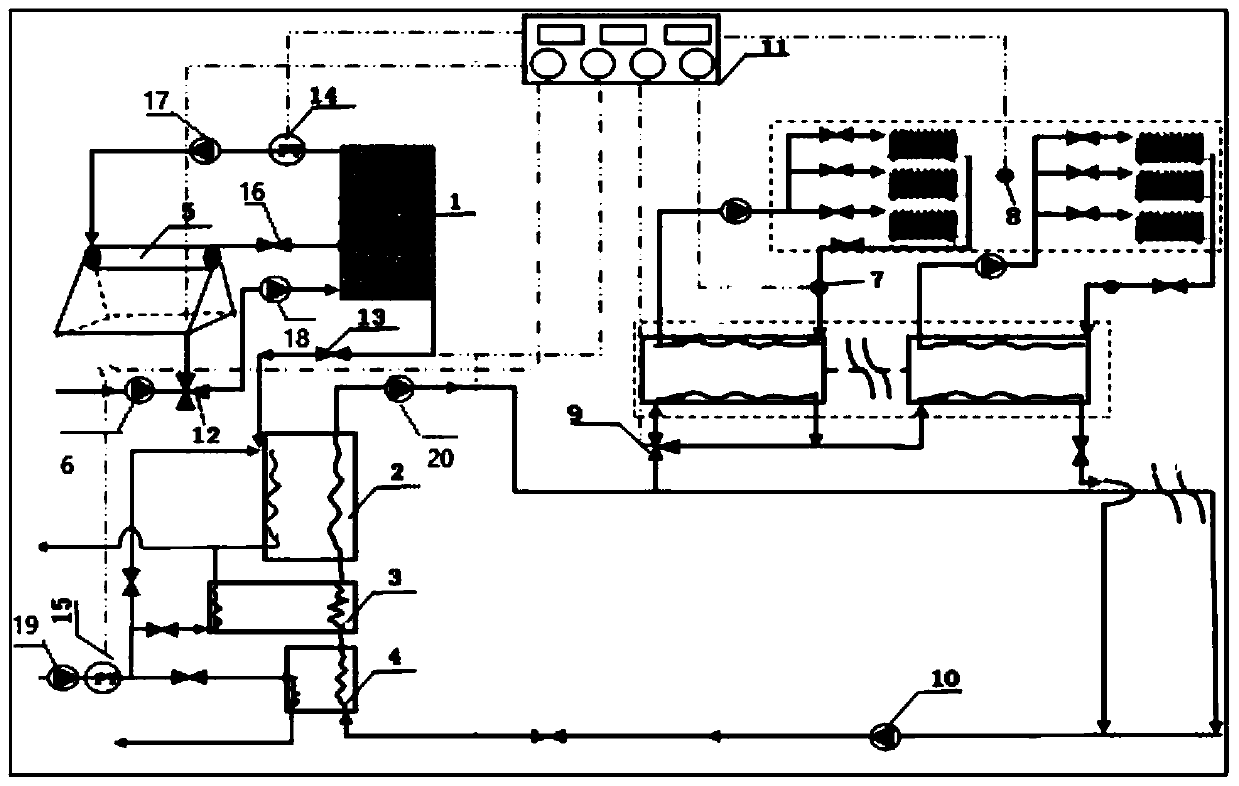

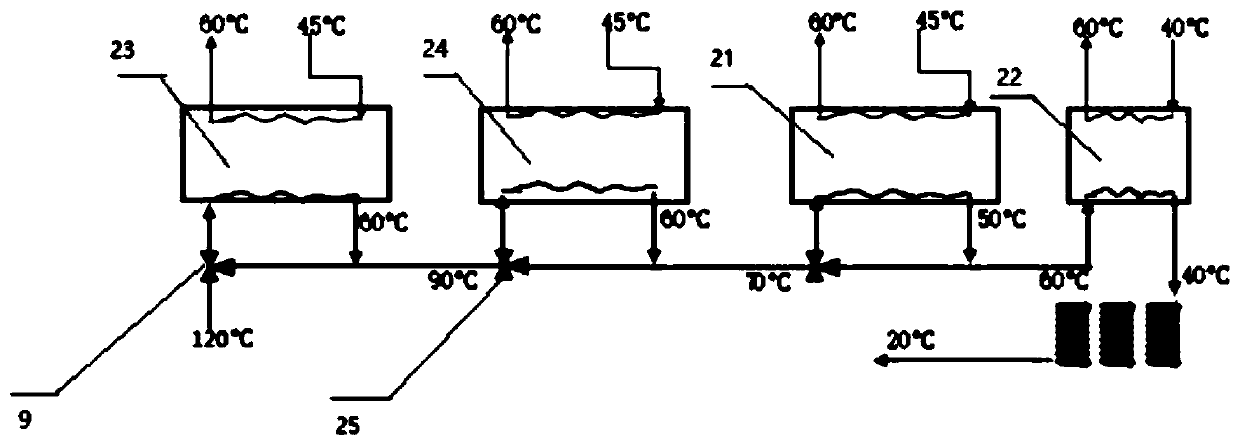

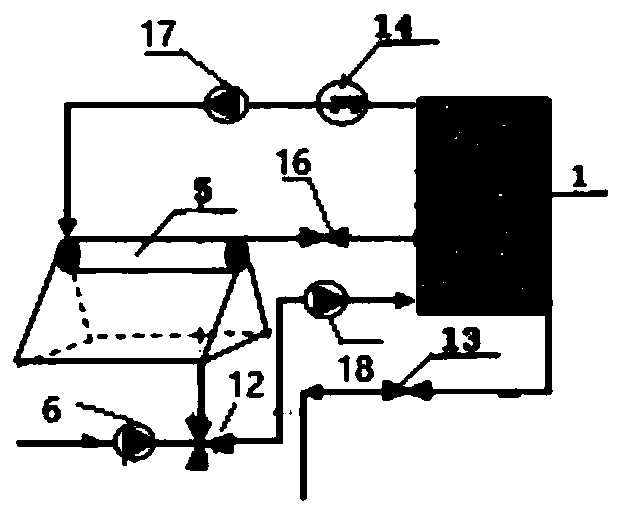

[0042] Such as figure 1 The shown main control device 11 adopts a PLC controller or other controllers, and the main control device 11 receives data detected by sensors such as the first mass flow sensor 14, the second mass flow sensor 15, the indoor temperature detector 8, and the temperature detector 7. Signals are sent to actuators such as the first electromagnetic three-way valve 12 and the electromagnetic three-way valve 9 of the first cascade heat exchange station to make them act.

[0043] The heat storage unit includes a solar heat collector 5, a heat accumulator 1, a first mass flow sensor 14, a first circulating water pump 17, a second circulating water pump 18, a third circulating water pump 6, a first electromagnetic three-way valve 12, a first Temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com